Model Number: D201

Plastic Modling Type: injection

Processing Service: Moulding

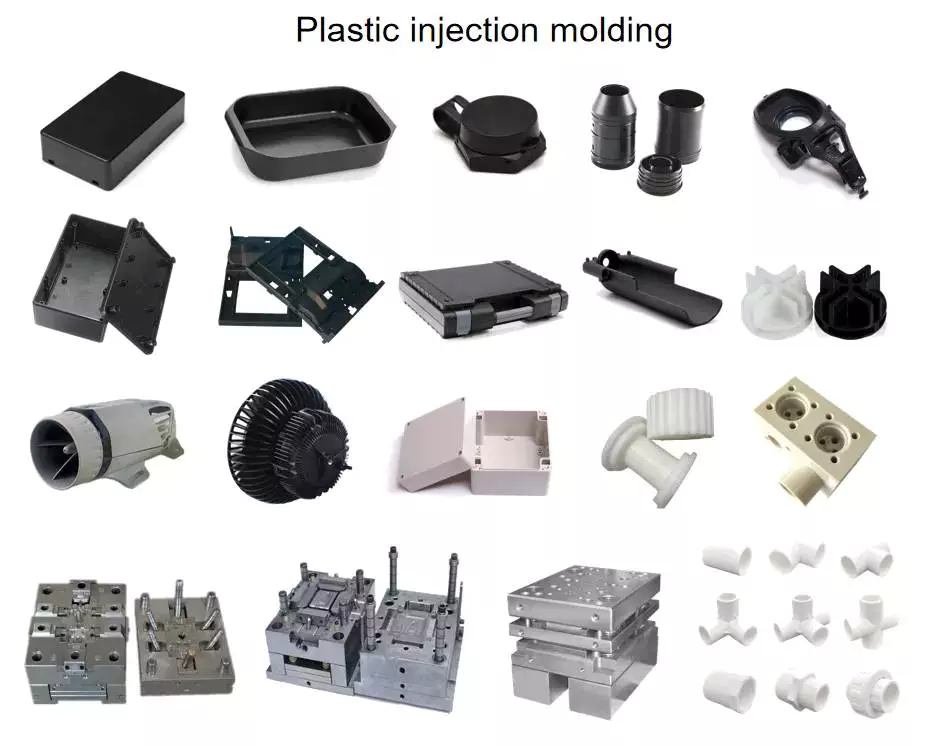

Name: Cheap Price OEM Plastic Injection CZPT Injection Molded Parts

Color: Red ,Yellow,Green,Natural, Black, white etc

OEM & ODM: yes

Free samples: yes

Size: Customized Size

Usage: Mechanical Turn Parts

Certification: ISO9001:2008

Drawing Format: STEP

Service: Customized OEM

Process: Injection Plastic Modling

Packaging Details: silicone rubber feet packed in plastic bag, carton or wooden cases.Or as customers request details.

Port: ZheJiang g, ZheJiang or HangZhou

Company information HangZhou Weichuang Rubber & Plastic Co. Ltd. is a modern high-tech enterprise in the integration of R&D, production and market expansion of high performance engineering rubber and plastic products. Our products are widely used in food machinery, beer and beverage machinery, steel rolling, railways, mining machinery, textile machinery, automobiles, automated conveyor equipment, etc. We maintain a leading level for more than 20 years by have a group of professional technicians, using advanced equipment, operating under a complete scientific management system and testing for quality.Our company maintains dozens of numerical control devices, advanced molding integration production lines, and complete testing equipment like hardness tester, Rheometer and tensile machine etc. We passed ISO 9001 by managing every production chain scientifically. All of our products use environment friendly material and is tested strictly from source material to production to delivery processes. Our company can produce various high challenging parts and was invited many times to improve machines and develop new type of parts according to customers’ requests; increasing the performance of machines, productivity and gained good reputations. Our products are widely sold in China and exported to Europe, America and South Asia. Our main products: all kinds of nylon bushings, wheels, slides, carrier rollers, gears, scale boards and other irregular parts; all kinds of ultra-high molecular weight PE(UHMW-PE) plate and other irregular parts; all kinds of injection molding parts with different material; all kinds of polyurethane plate and wheels ; all kinds of rubber products ; all kinds of oil nylon and large casting MC nylon irregular parts.

Cheap Price OEM Plastic Injection CZPT Injection Molded Parts Feature: 1, High Wear-resistance 2, Good Anti-corrosion resistance 3, Good self-lubrication 4, Very high-impact resistance 5, Very good electrical insulation 6, High inadhesion resistance 7, Non-toxic and clean property

| Material | PU/HDPE/UHMW-PE/MC NYLON/PA66/POM/TEFLON/PVDF/PPS/PEEK/PSU etc.As you like. | ||||

| General size | According to your drawings. | ||||

| Density | 1.2g/cm2 | ||||

| Color | Natural, Black, Yellow, Red etc. Customized. any color is ok. | ||||

| Advantage | One stop procurement | ||||

| Diameter | 1-200mm, or customized | ||||

| Price | Factory price offered | ||||

| OEM/ODM | Customers provide design or photo or we create design according to customers’requirements. | ||||

| Certification | ISO9001 | ||||

| Free sample | Yes | ||||

| Shape | sheet, rod, tube, gear, pulley, CZPT rail, and so on. | ||||

| Shipment | Fedex, DHL,UPS, Sea transport etc. | ||||

| Packing | Plastic bags, Cartons, Wodden case, Pallet, Container etc. | ||||

| Application | Automotive, Agricultural, Electronics, Industrial, Marine, Mining, Hydraulics, Valves, oil, Gas, Electrial, Construction | ||||

1.OEM Factory, saving your time and cost.2.If order comes to a certain quantity, we can reduce the molds cost.3.A team of professional track the process of your orders, payment and delivery, to save your time.

What are our service? 1.Professional analyse for your products2.Good suggestion on the material and technic3.Strict quality inspection 4.Suitable package5.safe and fast transportation 6.nice after-sales service

HangZhou Weichuang Rubber&Plastic Co.,Ltd., for over 20 years.

HangZhou Weichuang Rubber&Plastic Co.,Ltd., has been a leader in the research and development of thermoplastic products for short-run production. With our patented interchangeable injection molding system and comprehensive service, Weichuang provides a single-source responsibility for your product.We offer in-house CAD/CAM design services, engineering, and innovative solutions. Quality control and ISO 9001 compliance are the benchmarks of our commitment to customer satisfaction.

Packing & Delivery Packaging details: packed in plastic bags, cartons,wooden cases. or as your request.Delivery details: 15-30 days of plastic injection molding products, flexible for urgent orders.Transportation details: By Express such as DHL, UPS, TNT, FEDEX etc.

Welcome to contact me for inquiry:

Contact Us

Injection Molded Parts – Design Considerations

If you want to produce high-quality Injection molded parts, there are several factors to consider before the design process. These factors include the Surface finish, Material compatibility, and Tooling fabrication. This article will focus on some of these factors. Ultimately, you can save time and money by designing the parts in-house.

Design considerations

When creating a new part, or updating an existing part, design considerations for injection molded parts are critical. The decisions you make in these early stages of development can have a profound effect on the final product, and they can also have substantial cost and timing implications. In this guide, we’ll explore key design considerations, including how to maximize the efficiency of the injection molding process. We’ll also touch on how to optimize gate placement and parting lines.

When creating a new part, or updating an existing part, design considerations for injection molded parts are critical. The decisions you make in these early stages of development can have a profound effect on the final product, and they can also have substantial cost and timing implications. In this guide, we’ll explore key design considerations, including how to maximize the efficiency of the injection molding process. We’ll also touch on how to optimize gate placement and parting lines.

To ensure a successful injection molding process, part design must balance structural integrity and plastic fill volume. This means creating parts with relatively thin walls that have adequate support and avoid warping or sinking. To do this, injection molded parts often feature ribs or projections to strengthen the walls. However, too thin of a wall can result in excessive plastic pressure and air traps.

One of the most important design considerations for injection molded parts is the direction of the parting line. For many applications, a parting line is obvious, but for others it’s a little less obvious. The first step in designing an injection mold is to determine which direction it should open.

Another critical design consideration is the part’s ejection. If a part isn’t ejected properly, it will stick to the mold. A part that has too many undercuts or ribs will end up stuck on the mold’s side, making it difficult to eject it from the mold. A part that has a draft angle of at least five degrees is much easier to eject.

Another important design consideration for an injection molded part is the type of plastic used. Some plastics do not tolerate undercuts. However, some materials are able to tolerate undercuts of up to five percent. Undercuts are not ideal and can increase the complexity and cost of the injection mold.

Another design consideration for injection molded parts is the radius of edges. Sharp corners can create high molded-in stresses and can lead to failure points. A radius eliminates this stress by redistributing the stress more evenly throughout the part. This also facilitates flow of the material through the mold.

Surface finish

Injection molded parts are often finished with additional processing in order to improve their aesthetic quality. There are a variety of finishing processes, including machining and sanding, which give injected molded parts a particular look, feel, or texture. The surface finish of a plastic part affects both its aesthetics and its functionality. According to the Society of Plastics Industry, certain standards for surface finish are essential to the aesthetics and durability of plastic parts.

Surface finish of injection molded parts depends on the primary design goal. For instance, some designs may need a part to be aesthetically pleasing while others may want to enhance its functionality. Surface texture is often used by designers and engineers to achieve different aesthetic goals, such as improving the product’s perceived value. A textured surface may also help hide imperfections and improve the part’s non-slip qualities.

Surface finish is a critical aspect of plastic injection molding. It can affect material selection, tooling, and other process decisions. It is important to determine the desired surface finish early in the design phase. A skilled plastic injection molder can assist you in making this decision. In addition to determining the finish you need, a skilled molder can help you decide the best material for the job.

The PIA classification system defines four basic grades for surface finish. There are subcategories for each grade. Group A surface finish is smooth, and grade B and C finishes are textured. The former is the most common and economical finish and is most suitable for industrial parts. It can hide deformations and tooling marks, and is the least expensive finish type.

Surface finish of injection molded parts can vary greatly, and can be crucial to the performance and appearance of the part. Some companies prefer plastic parts with a glossy finish, while others prefer a textured surface for aesthetic reasons. While the former may be better for aesthetic purposes, rougher surfaces are often preferred for functional or mechanical parts.

Material compatibility

Material compatibility is important for the durability of your injection molded parts. You can use multiple materials in the same part by mixing resins. This is an ideal solution for parts that require adhesion, friction, or wear. Fast Radius can simplify the material selection process, optimize part design, and speed up production.

Material compatibility is important for the durability of your injection molded parts. You can use multiple materials in the same part by mixing resins. This is an ideal solution for parts that require adhesion, friction, or wear. Fast Radius can simplify the material selection process, optimize part design, and speed up production.

ABS is a thermoplastic polymer that can withstand a range of temperatures. Its low melting point means that it is easy to mold, and it has good chemical and moisture resistance. ABS also has good impact strength, and is highly durable. It is easy to recycle. Nylon is another versatile material for injection molding. It can be used for car tires, electrical components, and various apparel.

When choosing the material for your injection molded parts, keep in mind that the type of resin will determine their tolerance. Injection molding is compatible with a wide range of plastic resins. Some materials are more suitable than others for certain applications, and many plastics can be modified with stabilizers or additives to improve their properties. This flexibility allows the product development team to customize materials to achieve the performance characteristics they desire.

Polyamides are another great option for injection molding parts. Both natural and synthetic varieties of these plastics have excellent properties. However, they have some drawbacks. For instance, nylon injection molding is difficult and can result in inadequate filling. However, Nylon injection molding has many benefits, including high impact resistance and heat resistance.

Polybutylene terephthalate (PBT) is a high-molecular-weight polymer with excellent mechanical and chemical resistance. It is a good choice for components in the medical, automotive, and lighting industries. Its low water absorption and low flammability make it suitable for many applications.

Polyurethane (TPU) is another polymer option. It has excellent resistance to abrasion, chemicals, greases, and oils. It also has high temperature resistance, and is suitable for ozone environments. However, TPU is more expensive than TPE and requires drying before processing. Moreover, it has a short shelf life.

Tooling fabrication

Tooling fabrication for injection-molded parts is an important component of the manufacturing process. The right design of the mold can reduce the cost and time required for a finished product. For instance, choosing the right type of core for the mold can reduce the amount of material used in the part, which is necessary to produce a high-quality product. It is also important to choose a design that is easy to mill into a mold.

Tooling fabrication for injection-molded parts is an important component of the manufacturing process. The right design of the mold can reduce the cost and time required for a finished product. For instance, choosing the right type of core for the mold can reduce the amount of material used in the part, which is necessary to produce a high-quality product. It is also important to choose a design that is easy to mill into a mold.

Injection molding requires a mold with precise geometries. The mold tool must be constructed accurately and carefully to achieve the desired precision. It can be the biggest investment in the manufacturing process, but it is also critical to the success of a project. Large volume and high-precision parts often require more complex tooling, as they require the highest level of precision.

Tool steels typically used for injection moulding include H-13 and 420 stainless steel. Both of these materials are strong enough to produce parts of comparable hardness to wrought parts. These materials have low elongation values, so they are ideal for constructing injection moulding tools. Some of these steels also have excellent dimensional accuracy and are ideally suited for high-precision tool fabrication.

The process of plastic injection molding requires precise measuring and tooling fabrication. The mold must have the proper lead angle and space for the material to deform. Undercuts must be no larger than 5% of the diameter. Moreover, the injection molded part should be free of stripping or undercuts. Ideally, it should have a lead angle of 30o to 45o.

Various plastics can be used in the process of injection molding. The process can be used to produce cosmetic and end-use parts. Materials used in the molding process include silicone rubber and thermoplastics. If the part requires additional reinforcement, it can be reinforced with fibers, mineral particles, or flame retardant agents.

Increasingly advanced technologies have streamlined the process of tooling fabrication for injection moulded parts. The process has improved with the use of computer aided design, additive manufacturing, and CNC lathes. Approximately 15% of the cost of a finished injection molded part is spent on tooling fabrication.

editor by czh

Injection molding is the process of manufacturing plastic parts. It uses thermoplastic, thermoset, or elastomers to manufacture components. The range of materials is enormous and includes tens of thousands of different polymers. They are blended with other materials and alloys to produce a wide range of properties. Designers select the appropriate materials for the job based on the properties and functions desired in the finished part. During the mold design process, mold materials must be carefully chosen, as different materials require different molding parameters.

Injection molding is the process of manufacturing plastic parts. It uses thermoplastic, thermoset, or elastomers to manufacture components. The range of materials is enormous and includes tens of thousands of different polymers. They are blended with other materials and alloys to produce a wide range of properties. Designers select the appropriate materials for the job based on the properties and functions desired in the finished part. During the mold design process, mold materials must be carefully chosen, as different materials require different molding parameters. Injection molded parts must meet certain design considerations to ensure quality and precision. Design considerations include proper material choice, process control, and tool design. In addition, designers must consider the tolerance ranges for the parts to be produced. These tolerances will differ from molder to molder, and designers should discuss their specific needs with their molders before they begin production. Designers must also consider possible revisions to the mold, such as making the part more or less tighter.

Injection molded parts must meet certain design considerations to ensure quality and precision. Design considerations include proper material choice, process control, and tool design. In addition, designers must consider the tolerance ranges for the parts to be produced. These tolerances will differ from molder to molder, and designers should discuss their specific needs with their molders before they begin production. Designers must also consider possible revisions to the mold, such as making the part more or less tighter. Injection molding is a process in which plastic parts are formed by pressing melt into a mold. The process takes place in two stages. During the first step, the material is injected and heated, while the second stage is when the mold is opened and the part ejected. The part is then finished and ready for use.

Injection molding is a process in which plastic parts are formed by pressing melt into a mold. The process takes place in two stages. During the first step, the material is injected and heated, while the second stage is when the mold is opened and the part ejected. The part is then finished and ready for use. The cost of injection molded parts depends on many factors, including the complexity of the part and the mold design. Simpler designs, fewer CAD steps and simpler processes can help companies minimize costs. Another factor that affects the cost of injection molded parts is the geometry of the part. In general, complex geometries require more design work and tooling time. Additionally, thicker walls require more material than thin ones, which raises the cost of the part.

The cost of injection molded parts depends on many factors, including the complexity of the part and the mold design. Simpler designs, fewer CAD steps and simpler processes can help companies minimize costs. Another factor that affects the cost of injection molded parts is the geometry of the part. In general, complex geometries require more design work and tooling time. Additionally, thicker walls require more material than thin ones, which raises the cost of the part. One of the most critical design factors for injection molded parts is the wall thickness. The wall thickness affects many key characteristics of the part, from its surface finish to its structural integrity. Proper consideration of this factor can prevent costly delays due to mold issues or mold modifications. To avoid this problem, product designers must carefully consider the functional requirements of the part to determine the minimum and nominal wall thickness. In addition, they must also consider acceptable stress levels, since parts with excessively thin walls may require excessive plastic pressure and may create air traps.

One of the most critical design factors for injection molded parts is the wall thickness. The wall thickness affects many key characteristics of the part, from its surface finish to its structural integrity. Proper consideration of this factor can prevent costly delays due to mold issues or mold modifications. To avoid this problem, product designers must carefully consider the functional requirements of the part to determine the minimum and nominal wall thickness. In addition, they must also consider acceptable stress levels, since parts with excessively thin walls may require excessive plastic pressure and may create air traps. Surface finishes on injection molded parts are often used to mask defects, hide wear and tear, or enhance a product’s appearance. These finishes can also be useful when the product will come in contact with people’s hands. The surface texture you choose will depend on your desired functionality as well as the way you want to use the product. Generally, rougher textures provide better grip while masking minor molding imperfections. However, they can also make a product more difficult to release from the mold. This means that you may have to increase the draft angle of the mold. In order to get the best surface finish, the toolmaker and product designer must collaborate closely early in the design process.

Surface finishes on injection molded parts are often used to mask defects, hide wear and tear, or enhance a product’s appearance. These finishes can also be useful when the product will come in contact with people’s hands. The surface texture you choose will depend on your desired functionality as well as the way you want to use the product. Generally, rougher textures provide better grip while masking minor molding imperfections. However, they can also make a product more difficult to release from the mold. This means that you may have to increase the draft angle of the mold. In order to get the best surface finish, the toolmaker and product designer must collaborate closely early in the design process. The production volume of injection molded parts varies depending on the material being used. Large volumes of parts are expensive to produce, while small quantities can be produced for low cost. Injection molding requires a precise mold, which is CNC-machined from tool steel or aluminum. The mold has a negative of the part that is injected, a runner system, and internal water cooling channels to aid in cooling the part. Recent advances in 3D printing materials have made it possible to produce molds for low-volume injection molding. Previously, this was not financially viable due to the high cost of traditional mold making.

The production volume of injection molded parts varies depending on the material being used. Large volumes of parts are expensive to produce, while small quantities can be produced for low cost. Injection molding requires a precise mold, which is CNC-machined from tool steel or aluminum. The mold has a negative of the part that is injected, a runner system, and internal water cooling channels to aid in cooling the part. Recent advances in 3D printing materials have made it possible to produce molds for low-volume injection molding. Previously, this was not financially viable due to the high cost of traditional mold making. Design for manufacturability (DFMA) is an important part of the design process for injection-molded parts. This process helps to minimize costs and streamline the production process. It also helps in the prevention of problems during the manufacturing process. The process involves several steps that include part geometry, location of critical surfaces, material selection, and dimensioning. It is also crucial to consider the colors and tolerances, which can help to minimize scrap rates.

Design for manufacturability (DFMA) is an important part of the design process for injection-molded parts. This process helps to minimize costs and streamline the production process. It also helps in the prevention of problems during the manufacturing process. The process involves several steps that include part geometry, location of critical surfaces, material selection, and dimensioning. It is also crucial to consider the colors and tolerances, which can help to minimize scrap rates. Injection molding is a very versatile process that uses various types of plastic polymers. These plastics are extremely flexible and can be molded to take on any shape, color, and finish. They can also be customized to contain design elements, text, and safety instructions. Plastics are also lightweight, easily recycled, and can be hermetically sealed to prevent moisture from getting into the product.

Injection molding is a very versatile process that uses various types of plastic polymers. These plastics are extremely flexible and can be molded to take on any shape, color, and finish. They can also be customized to contain design elements, text, and safety instructions. Plastics are also lightweight, easily recycled, and can be hermetically sealed to prevent moisture from getting into the product. Texture design is a common feature of injection molded parts, which helps to raise the perceived value of the vehicle. While traditional manufacturing processes can produce limited textures, additive manufacturing allows for infinite designs. For example, a design that looks like a wood grain pattern may be printed on an aluminum car part.

Texture design is a common feature of injection molded parts, which helps to raise the perceived value of the vehicle. While traditional manufacturing processes can produce limited textures, additive manufacturing allows for infinite designs. For example, a design that looks like a wood grain pattern may be printed on an aluminum car part.