Product Description

Merchandise Description

Feature :

one) Design: We use the most advanced mould style software program AutoCAD, UG.

2) Manufacture: We use With advanced engineering, unmatched ability, professional products, and experienced experts to in shape our customers’ demands.

3) Mould foundation: LKM Brand name, HASCO and so on

four) Cavity/main substance: DIN1.2344, 738H, 718, 8407, S136, NAK80,P20, SKD-sixty one, NIMAX and so forth

five) Cavity Qty: Single/ Multi-cavity.

6) Lead time: 25-50days based mostly on the distinct merchandise

seven) Warranty: five hundred,000-1,000,000shots as per customers’ prerequisite

eight) Products material: PP, PA, POM, Abs, PET, Personal computer, PE,HDPE, PA66+GF,PVC, TPE, etc

9) Hot Runner: HASCO, YUDO, DME, Mold-Master

ten)Coloration Common: Pantone, Ral

11)Texture: VDI, YS

twelve)Price tag Terms: FOB HangZhou, China

13)Packaging: Wooden scenario or as per customers’ requirement

| Item identify: | Prototype |

| The company’s strengths: | one,Successful group with many years’ knowledge |

| two,Shipping in time | |

| 3,Superb equipment | |

| 4,Higher good quality and competitive value | |

| Substance: | Stomach muscles,POM,PP, PU,Pc,PA66,PVC,PVE, Aluminum,Steel |

| Colour | Any coloration, according to customers’ requirements. |

| Surfaces remedy: | mild colour,dumb coloration,rubber oil,pearlescent color,Silk-printing, anodize,chrome plating |

| File Formats: | Pro/engineer,Solidworks,UG,Car cad |

| Direct time | twenty five-50days based mostly on the various merchandise |

| Services | one,industrial layout |

| 2,Brass/Aluminum parts machining | |

| 3,Reverse engineering | |

| four,Injection molding | |

| 5,Rapid silicone mould and vacuum casting | |

| six,CNC prototype producing | |

| Business Fields | 1. Venture Improvement (ODM&OEM undertaking) for Industrial Design, ME and Components Layout, Tooling method and Mass creation. |

| 2. Magnesium- Alloy & Aluminum-Alloy component producing | |

| 3. Tooling procedure (Plastic mould, Stamp-Die, Die-Casting and Sand Casting) | |

| four. Metallic machining part production | |

| five. Fast Prototyping | |

| 6. Reduced quantity creation by CNC, RTV, and Quick-mould and so forth |

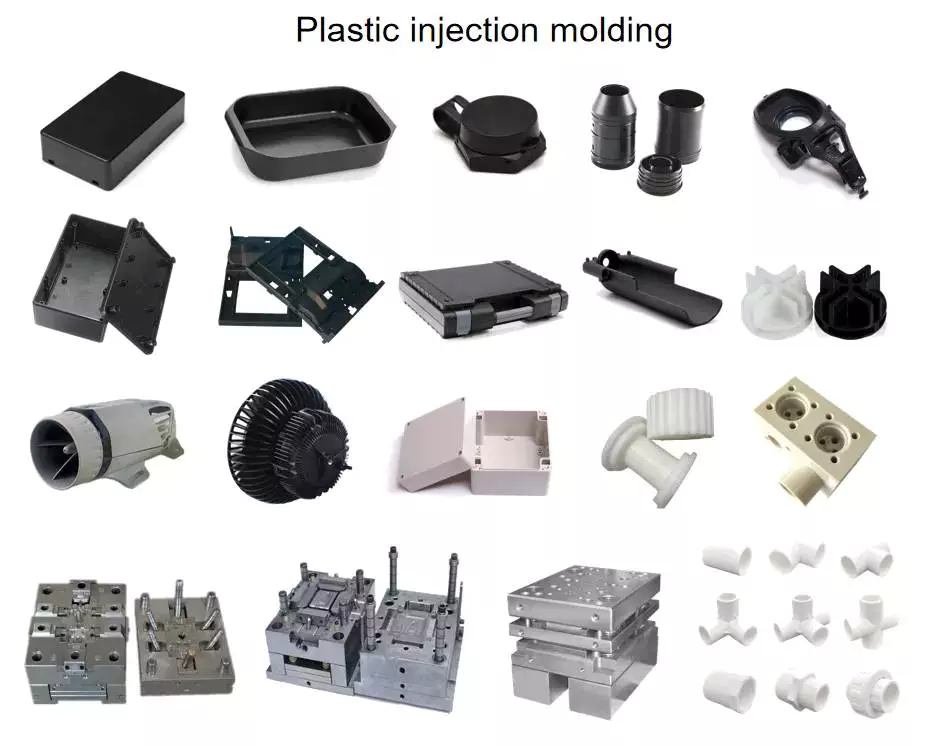

Thorough Pictures

Packaging & Shipping and delivery

Company Profile

ZheZheJiang ntong New Power Gear Co., Ltd. is a large-tech company integrating scientific research and production

The organization has 4500T, 2000T, 1000T and other big vulcanizing presses and machining tools, and has a scientific investigation and development team composed of twelve senior engineers.

Our principal items are wind tower internals series, rubber lining, nylon, polyurethane, flotation device stator, rotor sequence conveyor belt, support rod, substantial force hose, sealing strip, steel hose (stainless steel bellows) sequence , Silicon, unique rubber products and rubber and plastic sealing items. It is extensively utilized in metallurgy, mining, electric powered electricity, equipment components and other industries, and is nicely obtained by consumers.

All personnel of our business will devote to the vast variety of new and outdated consumers with far better items, much more favorable charges and better following-sales provider. I believe that ZheZheJiang ntong will turn into your without end good friend.

Workshop

Certifications

FAQ

Q1. Can you offer OEM & ODM service?

A: Yes.

Q2. What is your Trading Expression ,Payment Term?

A: 1)EXW,FOB, CFR or CIF.

two)T/T or L/C at sight by production buy,take Western Union or Paypal for sample freight.

Q3. Is the samples free?

A: Sample is Free, but the freight will refund you when your huge get.

This autumn. What is your MOQ?

A: 1 Pc is offered to our business,but the freight price for device cost will be quite substantial.

Q5. Can we print our own brand or manufacturer on the products?

A: Welcome, you can send your very own style of Symbol, we can make new mildew and print or label any Logo for you.

Q6. What is your nearby sea port?

A: ZheJiang or HangZhou port in China.

Q7. What’s provider in your plastic market?

A: PE,PP,PBT,PET,PA,PS,Computer,PVC,Ab muscles,EVA,TPE,TPU,TPR,TPV,PLA etc.

Q8. What’s material of your rubber?

A: HNBR,NBR,NR,FKM,EPDM,SIR,PU,ACM,FVMQ,SBR,CR,IIR and so on.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Household, Electronics, Automotive, Agricultural |

|---|---|

| Model Number: | Injection Molding |

| Brand Name: | Mach |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample Same as batch product

|

|---|

| Customization: |

Available

| Customized Request |

|---|

Designing Injection Molded Parts

Designing injection molded parts involves careful consideration of various parameters, including the wall thickness and draft angle. These factors are essential for a strong, durable part. Improper wall thickness can lead to sinking and warping defects. To avoid these issues, ensure that the walls of your injection-molded parts have a uniform thickness that does not vary too much from the rest of the part.

Designing out sharp corners in injection molded parts

When designing an injection molded part, it’s important to consider the corner radius. Sharp corners will create more stress, and this will lead to weak spots and cracks. Creating a radius around the corner helps distribute stress evenly and allows easier material flow and part ejection. Additionally, sharp corners in a mold can collect contaminants and create defects, including surface delamination.

When designing an injection molded part, it’s important to consider the corner radius. Sharp corners will create more stress, and this will lead to weak spots and cracks. Creating a radius around the corner helps distribute stress evenly and allows easier material flow and part ejection. Additionally, sharp corners in a mold can collect contaminants and create defects, including surface delamination.

Sharp corners in injection molded parts are a common source of stress and can cause the part to become damaged during the manufacturing process. In addition to trapping air, sharp corners may also lead to localized high temperatures that degrade the part. To reduce these risks, consider adding radii to all sharp corners.

Another important design factor to consider is wall thickness. Parts that have a smooth transition between sections should be designed with a minimum of five millimeters of wall thickness. Anything thicker will increase production cycle time and may also negatively impact mechanical properties. The use of fillets and chamfers can also help avoid these problems.

Designing out sharp corners in injection molded components can prevent costly problems from occurring during the manufacturing process. While the process is simple and straightforward, it needs to be done correctly to ensure quality. By following best practices, designers can ensure their parts won’t develop any problems or sink, warp, or voids. A poor design can also cause damage to the mold, which can cost thousands of dollars and hundreds of hours to redesign.

When designing injection molded parts, designers should consider the following guidelines. Incorporate internal and external radiuses. The internal radius (also called a fillet radius) is designed into the mold for improved quality and strength during the molding process. This radius is typically located on the inside corners or the bottom of a compartment. It can also be used for connecting walls and ribs. An external radius, on the other hand, is known as a round radius.

A right-angled part with sharp corners has a tendency to be loaded by pushing the vertical wall to the left. This creates a high-level of molded-in stress in the part. The resulting part may be weaker than expected because of the increased stress on the corner.

Importance of uniform wall thickness

Uniform wall thickness is a critical factor when designing injection-molded parts. This ensures that molten polymers can flow efficiently throughout the part. Additionally, it facilitates ideal processing. Varying wall thickness can cause problems during molding, such as air trapping, unbalanced filling, and weld lines. To ensure that your injection-molded parts are uniform, consult a plastic injection molding company that specializes in uniform wall thickness.

Injection-molded parts are more durable when the walls are uniform. A thin wall reduces the volume of material used in the part. However, thin walls can break during ejection. In addition, thin walls increase the possibility of voids. To prevent such problems, use larger machines that can produce parts with uniform wall thickness. This way, parts are easier to handle and ship.

Another important factor is the presence of gussets. These are support structures that stick out from a part’s surface. Gussets are useful for preventing warping, because they provide rigidity to thin unsupported sections. For this reason, gussets are essential when designing an injection-molded part.

Uniform wall thickness is especially critical in parts that have bends or rims. A uniform thickness helps maintain the mechanical strength and appearance of a part. However, this can be tricky as you may need to balance optical properties with mechanical ones. At Providence, we have the experience to help you navigate these challenges and produce quality parts.

Proper wall thickness is important for many reasons. It can affect both cost and production speed. The minimum wall thickness for injection molded parts depends on the part size, structural requirements, and flow behavior of the resin. Typically, injection molded parts have walls that are 2mm to 4mm thick. However, thin wall injection molding produces parts with walls as thin as 0.5mm. If you’re having trouble choosing the right wall thickness, consult an experienced injection molding company that can help you determine the appropriate wall thickness for your part.

Uneven wall thickness causes problems during injection molding. The uneven wall thickness may make the material flow through the part too quickly, or it may cause it to cool too slowly. This can lead to warping, twisting, or cracks. Even worse, uneven wall thickness can cause parts to become permanently damaged when they are ejected from the mold.

Importance of draft angle

Draft angles are an important part of design for injection molded parts. These angles are necessary because friction occurs on surfaces that come into contact with the mold during the molding process. A part with a simple geometry would only require a single degree of draft, but larger parts would need at least two degrees.

Draft angles are an important part of design for injection molded parts. These angles are necessary because friction occurs on surfaces that come into contact with the mold during the molding process. A part with a simple geometry would only require a single degree of draft, but larger parts would need at least two degrees.

Almost all parts requiring injection molding will require some amount of draft. The better the draft, the less likely the parts will have a poor finish and may bend or break. Furthermore, parts with inadequate draft will take longer to cool, extending cycle times. Moreover, if the parts are too thick or have too little draft, they may become warped.

Having a draft angle in injection molding is very important, especially if the mold has sharp corners. Without it, parts will come out scratched and will shorten the life of the mold. In some cases, parts may even not be able to eject from the mold at all. To prevent this, air needs to be allowed to get between the plastic and metal. This allows air to escape and prevents warping during ejection.

The importance of draft angle is often overlooked in the design process. Adding this angle to the mold can help prevent problems with mold release and reduce production costs. A draft angle will also allow parts to release from the mold more easily and will lead to better cosmetic finishes and fewer rejected parts. Additionally, it will reduce the need for costly elaborate ejection setups.

Draft angle should be added to the design as early as possible. It’s crucial for the success of the injection molding process, so it is best to incorporate it early in the design process. Even 3D printed parts can benefit from this detail. The size of the draft angle is also important, especially for core surfaces.

A draft angle can be large or small. The larger the draft angle, the easier it is to release the mold after the mold is completed. However, if the draft angle is too small, it can lead to scrapes on the edges or large ejector pin marks. Draft angles that are too small can lead to cracks and increase mold expenses.

Cost

There are many factors that contribute to the cost of injection-molded parts, including the material used for the mold and the complexity of the design. For example, larger parts will require a larger injection mold, which will cost more to manufacture. Additionally, more complex parts may require a mold with special features. Mold makers can advise you on how to design your part in order to reduce the overall cost of an injection-molded part.

There are many factors that contribute to the cost of injection-molded parts, including the material used for the mold and the complexity of the design. For example, larger parts will require a larger injection mold, which will cost more to manufacture. Additionally, more complex parts may require a mold with special features. Mold makers can advise you on how to design your part in order to reduce the overall cost of an injection-molded part.

One of the biggest costs related to the production of injection molded parts is the cost of the tooling. Tooling costs can reach $1,000 or more, depending on the design, materials, and finishing options. Tooling costs are less if the part quantity is small and repeatable. Higher part volumes may require a new mold and tooling.

Injection-molded parts’ cost depends on the material used and the price of procuring the material. The type of material also influences how long the part will last. Plastics that contain high percentages of glass fibers are abrasive and can damage an injection mold. Therefore, they are more expensive but may not be necessary for certain applications. Additionally, the material’s thermal properties may also affect the cycle time.

Mold size is another factor that impacts the cost. Larger molds require more CNC machinery and building space than smaller molds. Additionally, the complexity of the part will also impact the cost. Injection molds with sharp corners and complex ribs will cost more than small injection molds without intricate designs.

Injection molding is a complex process that requires a variety of moving parts. During the process, a critical piece of equipment is the injection die. This machine is a large part of the process, and comes in different sizes and shapes. Its purpose is to accept the hot plastic and machine it to extremely precise tolerances.

If your project requires a complex product with a high degree of complexity, injection molding is an excellent choice. It is ideal for initial product development, crowdfunding campaigns, and on-demand production. Mold modifications can also lower the cost of injection molding.

editor by CX 2023-04-10

Designing out sharp corners on injection molded components can be a challenging process. There are several factors to consider that impact how much corner radius you need to design out. A general rule is to use a radius that is about 0.5 times the thickness of the adjacent wall. This will prevent sharp corners from occurring on a part that is manufactured from injection molding.

Designing out sharp corners on injection molded components can be a challenging process. There are several factors to consider that impact how much corner radius you need to design out. A general rule is to use a radius that is about 0.5 times the thickness of the adjacent wall. This will prevent sharp corners from occurring on a part that is manufactured from injection molding. The uniformity of wall thickness is an essential factor in the plastic injection molding process. It not only provides the best processing results, but also ensures that the molded part is consistently balanced. This uniformity is especially important for plastics, since they are poor heat conductors. Moreover, if the wall thickness of an injection molded part varies, air will trap and the part will exhibit a poorly balanced filling pattern.

The uniformity of wall thickness is an essential factor in the plastic injection molding process. It not only provides the best processing results, but also ensures that the molded part is consistently balanced. This uniformity is especially important for plastics, since they are poor heat conductors. Moreover, if the wall thickness of an injection molded part varies, air will trap and the part will exhibit a poorly balanced filling pattern. The use of 3D printed molds allows manufacturers to manufacture a wide range of injection molded parts. However, 3D-printed molds are not as strong as those made from metallic materials. This means that they do not withstand high temperatures, which can degrade them. As such, they are not suitable for projects that require smooth finishing. In order to reduce this risk, 3D-printed molds can be treated with ceramic coatings.

The use of 3D printed molds allows manufacturers to manufacture a wide range of injection molded parts. However, 3D-printed molds are not as strong as those made from metallic materials. This means that they do not withstand high temperatures, which can degrade them. As such, they are not suitable for projects that require smooth finishing. In order to reduce this risk, 3D-printed molds can be treated with ceramic coatings. When creating a new part, or updating an existing part, design considerations for injection molded parts are critical. The decisions you make in these early stages of development can have a profound effect on the final product, and they can also have substantial cost and timing implications. In this guide, we’ll explore key design considerations, including how to maximize the efficiency of the injection molding process. We’ll also touch on how to optimize gate placement and parting lines.

When creating a new part, or updating an existing part, design considerations for injection molded parts are critical. The decisions you make in these early stages of development can have a profound effect on the final product, and they can also have substantial cost and timing implications. In this guide, we’ll explore key design considerations, including how to maximize the efficiency of the injection molding process. We’ll also touch on how to optimize gate placement and parting lines. Material compatibility is important for the durability of your injection molded parts. You can use multiple materials in the same part by mixing resins. This is an ideal solution for parts that require adhesion, friction, or wear. Fast Radius can simplify the material selection process, optimize part design, and speed up production.

Material compatibility is important for the durability of your injection molded parts. You can use multiple materials in the same part by mixing resins. This is an ideal solution for parts that require adhesion, friction, or wear. Fast Radius can simplify the material selection process, optimize part design, and speed up production. Tooling fabrication for injection-molded parts is an important component of the manufacturing process. The right design of the mold can reduce the cost and time required for a finished product. For instance, choosing the right type of core for the mold can reduce the amount of material used in the part, which is necessary to produce a high-quality product. It is also important to choose a design that is easy to mill into a mold.

Tooling fabrication for injection-molded parts is an important component of the manufacturing process. The right design of the mold can reduce the cost and time required for a finished product. For instance, choosing the right type of core for the mold can reduce the amount of material used in the part, which is necessary to produce a high-quality product. It is also important to choose a design that is easy to mill into a mold. Injection molding is the process of manufacturing plastic parts. It uses thermoplastic, thermoset, or elastomers to manufacture components. The range of materials is enormous and includes tens of thousands of different polymers. They are blended with other materials and alloys to produce a wide range of properties. Designers select the appropriate materials for the job based on the properties and functions desired in the finished part. During the mold design process, mold materials must be carefully chosen, as different materials require different molding parameters.

Injection molding is the process of manufacturing plastic parts. It uses thermoplastic, thermoset, or elastomers to manufacture components. The range of materials is enormous and includes tens of thousands of different polymers. They are blended with other materials and alloys to produce a wide range of properties. Designers select the appropriate materials for the job based on the properties and functions desired in the finished part. During the mold design process, mold materials must be carefully chosen, as different materials require different molding parameters. To get the best results from your injection molded parts, you must ensure that they meet certain design factors. These factors can help you achieve consistent parts and reduce cost. These guidelines can also help you to avoid common defects. One of the most common defects is warping, which is caused by the unintended warping of the part as it cools.

To get the best results from your injection molded parts, you must ensure that they meet certain design factors. These factors can help you achieve consistent parts and reduce cost. These guidelines can also help you to avoid common defects. One of the most common defects is warping, which is caused by the unintended warping of the part as it cools. Overhangs are areas of extra material that surround the surface of an injection molded part. This extra material is typically made of inexpensive material that is edged or glued on the part’s surface. The overhang material can be easily separated from the blank using a simple cutting process.

Overhangs are areas of extra material that surround the surface of an injection molded part. This extra material is typically made of inexpensive material that is edged or glued on the part’s surface. The overhang material can be easily separated from the blank using a simple cutting process. When designing injection molded parts, it is imperative to keep in mind their manufacturability. Injection molding allows for complex geometries and multiple functions to be combined into a single part. For example, a hinged part can have a single mold that can produce two different halves. This also decreases the overall volume of the part.

When designing injection molded parts, it is imperative to keep in mind their manufacturability. Injection molding allows for complex geometries and multiple functions to be combined into a single part. For example, a hinged part can have a single mold that can produce two different halves. This also decreases the overall volume of the part. Injection molded parts exhibit a range of mechanical and physical properties. These properties affect the performance of the parts. For example, they can affect electrical conductivity. Also, the degree of filling in the parts can determine their mechanical properties. Some studies have even found that filling content can affect the dimensional accuracy of the parts.

Injection molded parts exhibit a range of mechanical and physical properties. These properties affect the performance of the parts. For example, they can affect electrical conductivity. Also, the degree of filling in the parts can determine their mechanical properties. Some studies have even found that filling content can affect the dimensional accuracy of the parts. Injection molded parts often use fasteners for securing fastener elements in place. As shown in FIGS. 7 and 8 (two separate views), the fastener elements are integrated with the molded product, and they extend from one side. The fastener elements are designed to engage loop elements in the overlying layer. The palm-tree shaped fasteners are especially well-suited for this purpose, as their three-dimensional sides engage more loops than flat sides. These features result in a more secure closure.

Injection molded parts often use fasteners for securing fastener elements in place. As shown in FIGS. 7 and 8 (two separate views), the fastener elements are integrated with the molded product, and they extend from one side. The fastener elements are designed to engage loop elements in the overlying layer. The palm-tree shaped fasteners are especially well-suited for this purpose, as their three-dimensional sides engage more loops than flat sides. These features result in a more secure closure.