Design Quantity: SX-1001

Plastic Modling Type: injection

Processing Service: Moulding, Reducing

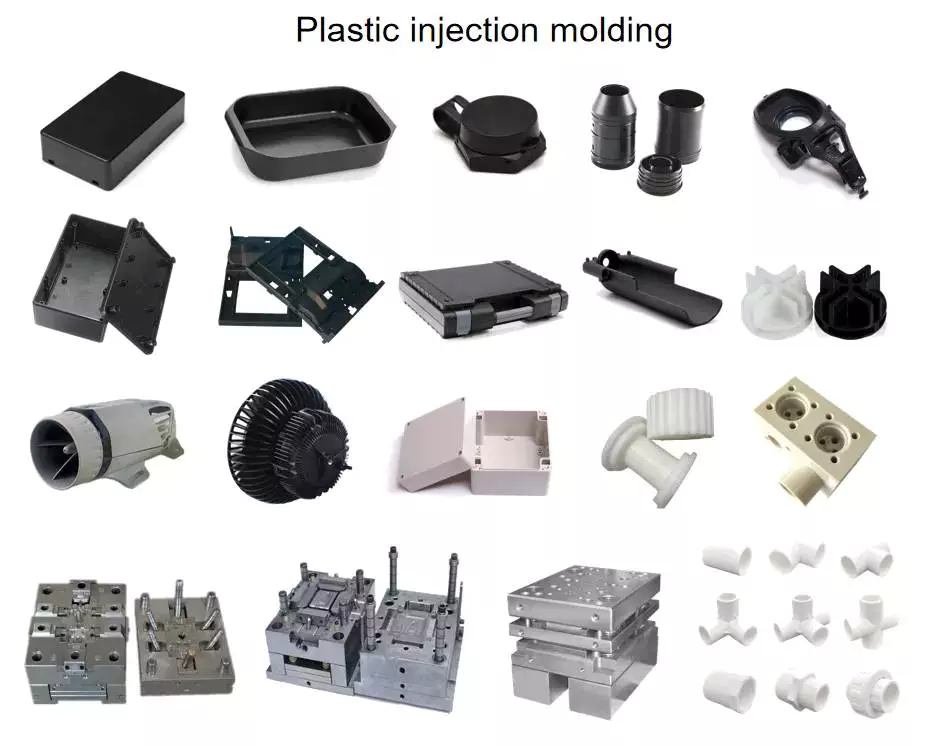

Merchandise Identify: Plastic injection molding fittings

Content: PP /PE/PVC/Abdominal muscles/PS/PA66/PMMA/TPU/TPR

Dimension: Tailored Size

Shade: Custom made Coloration

Logo: Customer Logo

Service: OEMODM

Drawing Structure: 2d/(PDF/CAD)3D(IGES/Step)

Procedure: Injection Plastic Modling

Mould Materials: S136, NAK80, 718H, 738,P20, and many others

Sureface Treatment: Sharpening/clean,texture/frosted, painting, plating, printing

Packaging Particulars: Plastic Bag+Carton BoxInner plastic bag, Injection mold maker customized high precision mouldings plastic CZPT products maker for factory outside carton box,very last is the pallet,all are dependent on the customers’ requirments

Port: ZheJiang port HangZhou port HangZhou port

We concentrate on Plastic Injection Products, pls contact us for more details OEM customized precision CNC plastic injection molding producer nylon abdominal muscles pp rubber injection molded provider plastic elements

| Model Variety | Customized |

| Plastic Modling Kind | Injection |

| Material | PP, PE, Abs, Nylon, Nylon sixty six, PA, POM, UPCV ect. |

| Color | Black, High High quality Electrical Iron Injection CZPT Garments Electric powered Iron Steam Iron Plastic Parts Mould White, Yellow, Pink, Eco-friendly, Blue,ect. |

| Size | Custmoized |

| Process | Injection Plastic Modling |

| Sample | Available |

| 3D drawing Structure | Stp/.Step/.Igs |

| Application | Intellectual Items, Vehicle spare elements, LED and so on |

Importance of Wall Thickness in Injection Molded Parts

When designing injection molded parts, it is important to keep the wall thickness uniform. Uneven wall thickness can lead to warping and sinking. To minimize these problems, injection molded parts should have a wall thickness of 40 to 60 percent of the adjacent wall. The thickness of the wall should also fit within the range recommended for the resin that is being used. If the wall thickness is too thick, it should be cored out. Unnecessary wall thickness alters the dimensions of the part, reduces its strength, and may require post-process machining.

Designing out sharp corners on injection molded parts

Designing out sharp corners on injection molded components can be a challenging process. There are several factors to consider that impact how much corner radius you need to design out. A general rule is to use a radius that is about 0.5 times the thickness of the adjacent wall. This will prevent sharp corners from occurring on a part that is manufactured from injection molding.

Designing out sharp corners on injection molded components can be a challenging process. There are several factors to consider that impact how much corner radius you need to design out. A general rule is to use a radius that is about 0.5 times the thickness of the adjacent wall. This will prevent sharp corners from occurring on a part that is manufactured from injection molding.

Sharp corners can obstruct the flow of plastic melt into the mold and create flaws on parts. They can also cause stress concentration, which can compromise the strength of the part. To avoid this, sharp corners should be designed out. Adding radii to the corners is also an effective way to avoid sharp angles.

Another common problem is the presence of overhangs. Injection molding parts with overhangs tend to have side-action cores, which enter from the top or bottom. As a result, the cost of making these parts goes up quickly. Moreover, the process of solidification and cooling takes up more than half of the injection molding cycle. This makes it more cost-effective to design parts with minimal overhangs.

Undercuts on injection molded parts should be designed with a greater radius, preferably one or two times the part’s wall thickness. The inside radius of corners should be at least 0.5 times the wall thickness and the outside radius should be 1.5 times the wall thickness. This will help maintain a consistent wall thickness throughout the part. Avoiding undercuts is also important for easy ejection from the mold. If undercuts are present, they can cause a part to stick inside the mold after it has cooled.

Keeping wall thickness uniform is another important issue when designing plastic parts. Inconsistent wall thickness will increase the chance of warping and other defects.

Adding inserts to injection molded parts

Adding inserts to injection molded parts can be a cost-effective way to enhance the functionality of your products. Inserts are usually manufactured from a wide range of materials, including stainless steel, brass, aluminum, bronze, copper, Monel, nickel/nickel alloy, and more. Selecting the right material for your parts depends on the application. Choosing the correct material can help prevent defects and keep production cycles short. The insert material should be durable and resist deformation during the injection molding process. It must also be thin enough to provide the desired grip and have a proper mold depth.

The benefits of adding inserts to injection molded parts include the ability to design parts with unique shapes. These parts can be aesthetically pleasing, while still remaining durable and resistant to wear and tear. In addition, insert molding allows products to have a good external finish. In addition to being cost-effective, insert molding is considered a more efficient manufacturing method than other conventional methods.

Adding inserts to injection molded parts is an excellent way to enhance the strength and performance of your products. There are many different types of inserts, including threaded nuts, bushings, pins, and blades. Some types are even available with knurled outer surfaces that help them adhere to plastic.

In addition to being cost-effective, insert molding is environmentally friendly and compatible with many types of materials. Typical inserts are made of metal or plastic. Depending on the application, stiffening inserts may also be made from wood.

Importance of uniform wall thickness

The uniformity of wall thickness is an essential factor in the plastic injection molding process. It not only provides the best processing results, but also ensures that the molded part is consistently balanced. This uniformity is especially important for plastics, since they are poor heat conductors. Moreover, if the wall thickness of an injection molded part varies, air will trap and the part will exhibit a poorly balanced filling pattern.

The uniformity of wall thickness is an essential factor in the plastic injection molding process. It not only provides the best processing results, but also ensures that the molded part is consistently balanced. This uniformity is especially important for plastics, since they are poor heat conductors. Moreover, if the wall thickness of an injection molded part varies, air will trap and the part will exhibit a poorly balanced filling pattern.

Uniform wall thickness also helps reduce shrinkage. Different materials have different shrinkage rates. For instance, thick parts take longer time to cool than thin ones. As the part’s thickness increases, cooling time doubles. This relationship is due to the one-dimensional heat conduction equation, which shows that heat flows from the center of the part toward the cooling channel. However, this relationship does not hold for all types of plastics.

The general rule for maintaining uniform wall thickness in injection molded parts is that walls should be no thicker than 3mm. In some cases, thicker walls can be used, but they will significantly increase production time and detract from the part’s aesthetic appeal and functionality. Furthermore, the thickness of adjacent walls should be no thicker than 40-60% of each other.

The uniformity of wall thickness is critical to the overall quality and efficiency of the injection molding process. An uneven wall thickness can cause twisting, warping, cracking, and even collapse. A uniform wall thickness also reduces residual stress and shrinkage. Injection molded parts are more stable when the wall thickness is uniform.

An injection molded part with thick walls can be problematic, especially when the molded parts are shaped like a cube. A non-uniform wall thickness can result in problems and costly retooling. Fortunately, there are solutions to this problem. The first step is to understand the problem areas and take action.

Using 3D printing to fabricate molds

The use of 3D printed molds allows manufacturers to manufacture a wide range of injection molded parts. However, 3D-printed molds are not as strong as those made from metallic materials. This means that they do not withstand high temperatures, which can degrade them. As such, they are not suitable for projects that require smooth finishing. In order to reduce this risk, 3D-printed molds can be treated with ceramic coatings.

The use of 3D printed molds allows manufacturers to manufacture a wide range of injection molded parts. However, 3D-printed molds are not as strong as those made from metallic materials. This means that they do not withstand high temperatures, which can degrade them. As such, they are not suitable for projects that require smooth finishing. In order to reduce this risk, 3D-printed molds can be treated with ceramic coatings.

Using 3D printing to fabricate injection molds can help reduce costs and lead times, allowing manufacturers to bring their products to market faster. This process also has the advantage of being highly efficient, as molds made using 3D printing can be designed to last for many years.

The first step in fabricating an injection mold is to design a design. This design can be complex or simple, depending on the part. The design of the mold can be intricate. A simple example of a mold would be a red cup, with an interior and exterior. The interior portion would have a large cone of material protruding from the other side.

Injection molding is an effective way to produce thousands of parts. However, many engineering companies do not have access to expensive 3D printers. To solve this problem, companies should consider using outside suppliers. In addition to speeding up the manufacturing process, 3D printing can reduce the cost of sample parts.

Plastic injection molding still remains the most popular method for high volume production. However, this process requires a large up-front capital investment and takes a while to adapt. Its advantages include the ability to use multiple molds at once, minimal material wastage, and precision dosing. With an increasing number of materials available, 3D printing can be a smart option for companies looking to manufacture a variety of plastic parts.

editor by czh2023-02-15

When developing a medical device, there are several design considerations to be made to create a quality injection molded part. Typically, product designers want to minimize the amount of material needed to fill the part while still maintaining the structural integrity of the product. To this end, injection molded parts often have ribs to stiffen the relatively thin walls. However, improper placement of ribs or projections can create molding problems.

When developing a medical device, there are several design considerations to be made to create a quality injection molded part. Typically, product designers want to minimize the amount of material needed to fill the part while still maintaining the structural integrity of the product. To this end, injection molded parts often have ribs to stiffen the relatively thin walls. However, improper placement of ribs or projections can create molding problems. Injection molded parts exhibit a range of mechanical and physical properties. These properties affect the performance of the parts. For example, they can affect electrical conductivity. Also, the degree of filling in the parts can determine their mechanical properties. Some studies have even found that filling content can affect the dimensional accuracy of the parts.

Injection molded parts exhibit a range of mechanical and physical properties. These properties affect the performance of the parts. For example, they can affect electrical conductivity. Also, the degree of filling in the parts can determine their mechanical properties. Some studies have even found that filling content can affect the dimensional accuracy of the parts. Injection molded parts often use fasteners for securing fastener elements in place. As shown in FIGS. 7 and 8 (two separate views), the fastener elements are integrated with the molded product, and they extend from one side. The fastener elements are designed to engage loop elements in the overlying layer. The palm-tree shaped fasteners are especially well-suited for this purpose, as their three-dimensional sides engage more loops than flat sides. These features result in a more secure closure.

Injection molded parts often use fasteners for securing fastener elements in place. As shown in FIGS. 7 and 8 (two separate views), the fastener elements are integrated with the molded product, and they extend from one side. The fastener elements are designed to engage loop elements in the overlying layer. The palm-tree shaped fasteners are especially well-suited for this purpose, as their three-dimensional sides engage more loops than flat sides. These features result in a more secure closure. When designing an injection molded part, it’s important to consider the corner radius. Sharp corners will create more stress, and this will lead to weak spots and cracks. Creating a radius around the corner helps distribute stress evenly and allows easier material flow and part ejection. Additionally, sharp corners in a mold can collect contaminants and create defects, including surface delamination.

When designing an injection molded part, it’s important to consider the corner radius. Sharp corners will create more stress, and this will lead to weak spots and cracks. Creating a radius around the corner helps distribute stress evenly and allows easier material flow and part ejection. Additionally, sharp corners in a mold can collect contaminants and create defects, including surface delamination. Draft angles are an important part of design for injection molded parts. These angles are necessary because friction occurs on surfaces that come into contact with the mold during the molding process. A part with a simple geometry would only require a single degree of draft, but larger parts would need at least two degrees.

Draft angles are an important part of design for injection molded parts. These angles are necessary because friction occurs on surfaces that come into contact with the mold during the molding process. A part with a simple geometry would only require a single degree of draft, but larger parts would need at least two degrees. There are many factors that contribute to the cost of injection-molded parts, including the material used for the mold and the complexity of the design. For example, larger parts will require a larger injection mold, which will cost more to manufacture. Additionally, more complex parts may require a mold with special features. Mold makers can advise you on how to design your part in order to reduce the overall cost of an injection-molded part.

There are many factors that contribute to the cost of injection-molded parts, including the material used for the mold and the complexity of the design. For example, larger parts will require a larger injection mold, which will cost more to manufacture. Additionally, more complex parts may require a mold with special features. Mold makers can advise you on how to design your part in order to reduce the overall cost of an injection-molded part. When designing injection molded parts, it’s essential to consider the wall thickness of the part. Ideally, the wall thickness is uniform across the entire part. This allows the entire mold cavity to fill without restriction, and reduces the risk of defects. Parts that don’t have uniform wall thickness will have high stresses at the boundary between two sections, increasing the risk of cracks, warping, and twisting. To avoid such stresses, designers can consider tapering or rounding the edges of the part to eliminate stress concentration.

When designing injection molded parts, it’s essential to consider the wall thickness of the part. Ideally, the wall thickness is uniform across the entire part. This allows the entire mold cavity to fill without restriction, and reduces the risk of defects. Parts that don’t have uniform wall thickness will have high stresses at the boundary between two sections, increasing the risk of cracks, warping, and twisting. To avoid such stresses, designers can consider tapering or rounding the edges of the part to eliminate stress concentration. There are two main types of runner systems: hot runner systems and cold runner systems. In a hot runner system, a runner nozzle delivers the molten plastic into the mold cavity. A cold runner system does not require the use of a nozzle and acts as a conduit for the molten plastic.

There are two main types of runner systems: hot runner systems and cold runner systems. In a hot runner system, a runner nozzle delivers the molten plastic into the mold cavity. A cold runner system does not require the use of a nozzle and acts as a conduit for the molten plastic. Thermostatic control of temperature in an injection molding process can make a significant impact on part quality. High mold temperatures should be regulated by using a temperature-controlled cooling unit. These devices are equipped with pumping systems and internal heaters. The temperature of the injected plastic determines the plastic’s flow characteristics and shrinkage. Temperature also influences the surface finish, dimensional stability, and physical properties of the finished product.

Thermostatic control of temperature in an injection molding process can make a significant impact on part quality. High mold temperatures should be regulated by using a temperature-controlled cooling unit. These devices are equipped with pumping systems and internal heaters. The temperature of the injected plastic determines the plastic’s flow characteristics and shrinkage. Temperature also influences the surface finish, dimensional stability, and physical properties of the finished product. To get the best results from your injection molded parts, you must ensure that they meet certain design factors. These factors can help you achieve consistent parts and reduce cost. These guidelines can also help you to avoid common defects. One of the most common defects is warping, which is caused by the unintended warping of the part as it cools.

To get the best results from your injection molded parts, you must ensure that they meet certain design factors. These factors can help you achieve consistent parts and reduce cost. These guidelines can also help you to avoid common defects. One of the most common defects is warping, which is caused by the unintended warping of the part as it cools. Overhangs are areas of extra material that surround the surface of an injection molded part. This extra material is typically made of inexpensive material that is edged or glued on the part’s surface. The overhang material can be easily separated from the blank using a simple cutting process.

Overhangs are areas of extra material that surround the surface of an injection molded part. This extra material is typically made of inexpensive material that is edged or glued on the part’s surface. The overhang material can be easily separated from the blank using a simple cutting process. When designing injection molded parts, it is imperative to keep in mind their manufacturability. Injection molding allows for complex geometries and multiple functions to be combined into a single part. For example, a hinged part can have a single mold that can produce two different halves. This also decreases the overall volume of the part.

When designing injection molded parts, it is imperative to keep in mind their manufacturability. Injection molding allows for complex geometries and multiple functions to be combined into a single part. For example, a hinged part can have a single mold that can produce two different halves. This also decreases the overall volume of the part.