Model Number: OEM

Shaping Mode: Plastic Injection Mould

Product Material: Steel, ABS, PPR, PC, PP, PVC, POM, PMMA, PS, PE, PET, PA, PBT, PEI, etc.

Product: Household Product

Cavity/Core Material: 718H, P20, NAK80, 2316, 2738, 2344

Base: LKM or by requested

Runner System: Hot runner, Cold runner

Cavity: Single cavity, multi cavities by requested

Finish: Corrosion word, Mirror finish, Brushed

Longevity: Available SHOTS will depend on the steel material you choose

Mould standard: HASCO, DME, MISUMI, or by requested etc.

Software: CAD, Pro-E, UG, etc

Main Technique: Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, etc.

Packaging Details: 1 Set Plastic auto body parts molding injection mold car interior parts plastic mold of Wooden case, or by request

Port: ZheJiang Port/HangZhou Port

| Main Technique Parameters | |

| Cavity/CoreMaterial | 718H, P20, NAK80, 2316, 2738, 2344 |

| Product Material | ABS, PPR, PC, PP, PVC, POM, PMMA, PS, PE, PET,PA, PBT, PEI, etc. |

| Base | LKM or by requested |

| Runner System | Hot runner, Cold runner |

| Cavity | Single cavity, multi cavities by requested (support similar products in 1 mould) |

| Finish | Corrosion word, Mirror finish, Brushed |

| Longevity | Available SHOTS will depend on the steel material you choose |

| Mould standard | HASCO, DME, MISUMI, or by requested etc. |

| Software | CAD, Pro-E, UG, etc |

| Main Technique | Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, etc. |

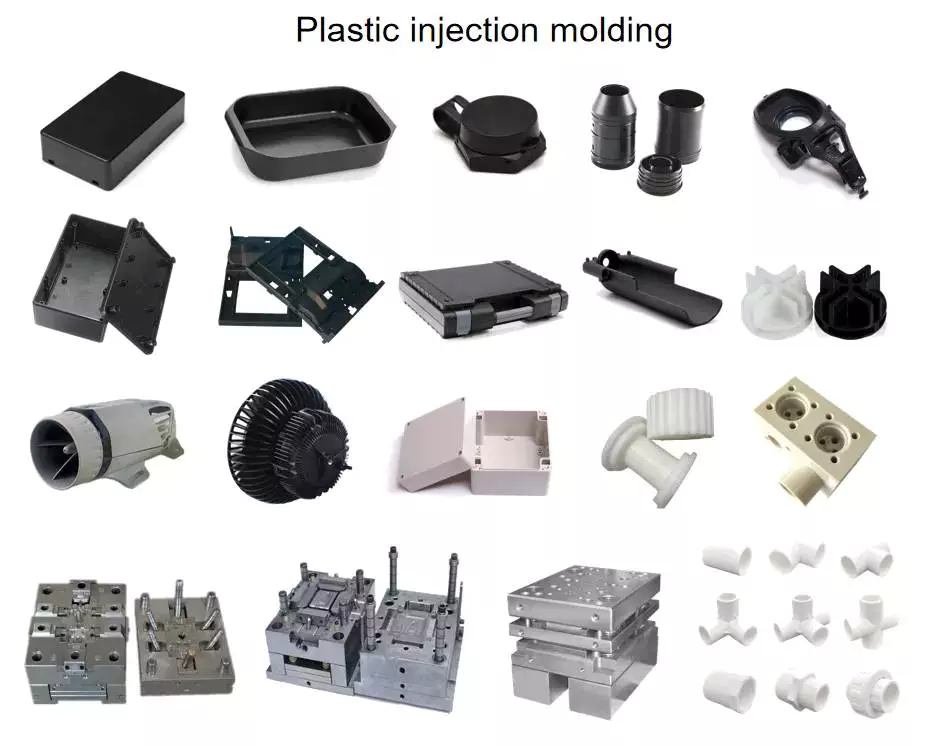

Product Display

Machine Feature:

1 Enhanced clamping mechanism to meet requirements for efficient production.

2 Excellent clamping features with optimized linkage mechanism to have faster and smooth operation.

3 Professional plasticizing unit is applicable for production of various raw materials, and to improve plasticize performance significantly.

4 Excellent injection performance with twin-cylinder injection mode, have more reliable and stable performance.

5 Professional platen optimization, the platen after finite element analysis and optimization has high rigidity and strength.

6 Centralized lubrication system with reliable protective configuration, quantitative distribution and centered lubrication, provide more professional lubrication protection and extend mechanical life.

7 New frame type structure, simple and clean appearance, with more reasonable stress on machine body and high rigidity.

More Products

Company Profile

About Us

Payment& Transport

FAQQ1: Are you a trading company or a manufacturer?

A1: We are a manufacturer, we supply the factory price with good quality, welcome to visit !

Q2:How about quality control in your factory?

A2: “ Quality is the key point, do what customers needs”

Q3: Is there complete machine include CZPT and other auxiliary equipment ?

A3: Yes ,what we are provide is the complete system and you will no need spend

a lot to find the suitable water chiller and color mixer…etc.

Q4: What is the language of the PLC and touch panel?

A4: English and Chinese, or other customized language

Q5: Can you help us with the shipment of this machine ?

A5: With honor ,we have our special shipment company which already cooperate

for long time, we will give you the best price we can. Also you can ask your own

shipping forwarder, we help you do other things. Customer satisfy, is our target.

Designing Injection Molded Parts

Injection molded parts are designed to work together to form a whole. While the small plastic toys like Legos aren’t typically fabricated for assembly, these products still require precision measurements. For this reason, the designs of injection molded parts should be perfected for manufacturing. The designs should also minimize error potential.

Design considerations for injection molded parts

When designing injection molded parts, it’s essential to consider the wall thickness of the part. Ideally, the wall thickness is uniform across the entire part. This allows the entire mold cavity to fill without restriction, and reduces the risk of defects. Parts that don’t have uniform wall thickness will have high stresses at the boundary between two sections, increasing the risk of cracks, warping, and twisting. To avoid such stresses, designers can consider tapering or rounding the edges of the part to eliminate stress concentration.

When designing injection molded parts, it’s essential to consider the wall thickness of the part. Ideally, the wall thickness is uniform across the entire part. This allows the entire mold cavity to fill without restriction, and reduces the risk of defects. Parts that don’t have uniform wall thickness will have high stresses at the boundary between two sections, increasing the risk of cracks, warping, and twisting. To avoid such stresses, designers can consider tapering or rounding the edges of the part to eliminate stress concentration.

The wall thickness of the injection molded part is important because it affects many key characteristics. Therefore, it is critical to take proper care in choosing the wall thickness to avoid costly delays caused by mold problems or mold modification. The nominal wall thickness should be determined based on the function and stress requirements of the part. Similarly, the minimum wall thickness should be calculated based on acceptable stress. Too thin a wall can result in air traps and excessive plastic pressure.

Injection molded parts that have sharp corners are a common cause of defects. Sharp corners create stress concentrations, poor flow patterns, and increased injection mold wear. To minimize these problems, designers should keep inside corners and outside corners at half the wall thickness. This will help minimize stress and ensure the integrity of the part.

Another important design consideration for injection molded parts is the thickness of the ribs. They should be at least two-thirds of the outer wall. Thicker ribs may result in sink marks on the outer surface. Undercuts also complicate the mold design and increase the cost of the part.

Tolerance variation is also an important consideration. It depends on materials, process control, and tool design. Tolerance variation varies from molder to molder, and designers should discuss critical tolerance requirements with molders. If the part has to be manufactured to a particular tolerance, designers should consider options for mold revisions to minimize the tolerance variance. Additionally, designers may need to intentionally design extra clearance. To compensate for such variation, the molder may remove some steel or modify the design. In some cases, interference can be solved by welding.

Design considerations for injection molded parts should be discussed with material science professionals early in the design process. This is critical because changes to the mold design can be costly. Therefore, achieving the best possible result is critical. By following design guidelines, manufacturers can avoid common defects. A uniform wall thickness is also important because non-uniform thickness can lead to warping the part as it cools.

Another important factor for injection molded parts is the flowability of the material in the mold cavity. The resin should be able to flow easily around rounded corners. For example, a molded part with a curved undercut will not eject properly from the mold if there’s no space between the two sides. For this reason, designers should consider the flowability of the molded material before deciding on a design.

Adding a runner system to an injection molding machine

There are two main types of runner systems: hot runner systems and cold runner systems. In a hot runner system, a runner nozzle delivers the molten plastic into the mold cavity. A cold runner system does not require the use of a nozzle and acts as a conduit for the molten plastic.

There are two main types of runner systems: hot runner systems and cold runner systems. In a hot runner system, a runner nozzle delivers the molten plastic into the mold cavity. A cold runner system does not require the use of a nozzle and acts as a conduit for the molten plastic.

The design of a hot runner mold should balance the activity of plastic solution and mold cavities. Ideally, a mold with two cavities is better balanced than one with three. However, it is important to remember that a three-cavity mold requires a manifold balance of human activities.

Plastic mold runner systems are crucial for ensuring consistent fill rates and pressure. Whether you are producing single or multiple-cavity plastic parts, a runner system will keep your processes consistent. When choosing a runner system, make sure you have the right one for your application.

Hot runner systems can reduce cycle times by as much as 10 to 30 percent. They help improve quality control and minimize material waste by keeping the plastic molten throughout the molding process. Moreover, they help save on plastic raw materials and energy. These features make them ideal for large production lines.

A hot runner system can also help prevent overfilling a cavity. Make sure that the volume of the hot runner is equal to the volume of the mold cavity. Otherwise, the plastic solution will be trapped inside the hot runner for too long and decompose.

Hot runner systems come in many varieties. One type of hot runner system is called the sprue hot runner system. This system uses a mechanical valve to open and close a nozzle. This type of hot runner is more effective and efficient than a general-purpose hot runner. However, it is also more expensive.

In a three-plate mold, the runner system is positioned between the core and cavity plates. When the mold is opened, the runner system automatically separates from the molded part. This eliminates the need for manual labor, but increases the cost of tooling.

The runner system is important for producing parts that are both thin and thick. The runner should be narrow but large so as not to create voids and improve the overall performance of the final product. Runner systems are also important for reducing the amount of energy needed to form and regrind the material.

A hot runner system is one way to improve the speed and accuracy of plastic molding. It helps avoid problems with waste by reducing the amount of plastic wasted. Furthermore, a hot runner system also prevents expensive repairs. By adding a runner system to an injection molding system, you will ensure better quality and precision, and avoid unnecessary downtime and costly repairs.

Hot runner systems are ideal for high-volume productions. However, they require a higher level of maintenance. In addition, hot runner systems are difficult to clean and often leave waste material. Hidden runners may also be inconvenient to remove, especially when changing materials or colors. They can also lead to sticking issues if they are made from thermally sensitive materials.

Using a thermally isolated cold injection unit

Thermostatic control of temperature in an injection molding process can make a significant impact on part quality. High mold temperatures should be regulated by using a temperature-controlled cooling unit. These devices are equipped with pumping systems and internal heaters. The temperature of the injected plastic determines the plastic’s flow characteristics and shrinkage. Temperature also influences the surface finish, dimensional stability, and physical properties of the finished product.

Thermostatic control of temperature in an injection molding process can make a significant impact on part quality. High mold temperatures should be regulated by using a temperature-controlled cooling unit. These devices are equipped with pumping systems and internal heaters. The temperature of the injected plastic determines the plastic’s flow characteristics and shrinkage. Temperature also influences the surface finish, dimensional stability, and physical properties of the finished product.

A thermally isolated cold injection unit allows mold operators to mold parts at lower temperatures than a conventional injection molding machine. The injection mold itself is composed of two steel halves. The two halves are connected by a mechanical hinge. During injection molding, a small amount of plastic is forced into the mold cavity. The injected plastic is then allowed to cool into a solid state. The molded part then falls out of the mold halves. The injected part then enters a bin to be collected.

The heat/cool injection molding process can improve the aesthetics of molded parts significantly. The effects of this technique are particularly apparent with amorphous resins, which do not form a skin during the injection phase. The molded parts have a higher gloss than with conventional molding techniques.

This process requires less clamping force than conventional injection molding and offers more design freedom. It also increases process capacity and materials savings. The process control for this process is more complex, with variables such as the amount of melt injection, water pressure, and water injection delay time.

The angle of repose is another criterion. A low angle indicates that the pellets are free-flowing, while an angle above 45deg indicates that the pellets are not free-flowing. This is important when processing nylon resins.

Plastic injection molding has made huge advances in recent decades. Today, most injection molds fall into one of two types: hot runner and cold runner. Each has its advantages and disadvantages. Understanding how they differ will help you decide which method is right for you.

Injection molding is a highly effective manufacturing process that gives manufacturers a competitive edge over their competition. Using this process produces high-quality plastic and metal parts with minimal waste and a low cycle time. The process is also extremely accurate and produces products with the perfect blend of flexibility and strength.

editor by czh

When developing a medical device, there are several design considerations to be made to create a quality injection molded part. Typically, product designers want to minimize the amount of material needed to fill the part while still maintaining the structural integrity of the product. To this end, injection molded parts often have ribs to stiffen the relatively thin walls. However, improper placement of ribs or projections can create molding problems.

When developing a medical device, there are several design considerations to be made to create a quality injection molded part. Typically, product designers want to minimize the amount of material needed to fill the part while still maintaining the structural integrity of the product. To this end, injection molded parts often have ribs to stiffen the relatively thin walls. However, improper placement of ribs or projections can create molding problems. Injection molded parts exhibit a range of mechanical and physical properties. These properties affect the performance of the parts. For example, they can affect electrical conductivity. Also, the degree of filling in the parts can determine their mechanical properties. Some studies have even found that filling content can affect the dimensional accuracy of the parts.

Injection molded parts exhibit a range of mechanical and physical properties. These properties affect the performance of the parts. For example, they can affect electrical conductivity. Also, the degree of filling in the parts can determine their mechanical properties. Some studies have even found that filling content can affect the dimensional accuracy of the parts. Injection molded parts often use fasteners for securing fastener elements in place. As shown in FIGS. 7 and 8 (two separate views), the fastener elements are integrated with the molded product, and they extend from one side. The fastener elements are designed to engage loop elements in the overlying layer. The palm-tree shaped fasteners are especially well-suited for this purpose, as their three-dimensional sides engage more loops than flat sides. These features result in a more secure closure.

Injection molded parts often use fasteners for securing fastener elements in place. As shown in FIGS. 7 and 8 (two separate views), the fastener elements are integrated with the molded product, and they extend from one side. The fastener elements are designed to engage loop elements in the overlying layer. The palm-tree shaped fasteners are especially well-suited for this purpose, as their three-dimensional sides engage more loops than flat sides. These features result in a more secure closure. Injection molded parts must meet certain design considerations to ensure quality and precision. Design considerations include proper material choice, process control, and tool design. In addition, designers must consider the tolerance ranges for the parts to be produced. These tolerances will differ from molder to molder, and designers should discuss their specific needs with their molders before they begin production. Designers must also consider possible revisions to the mold, such as making the part more or less tighter.

Injection molded parts must meet certain design considerations to ensure quality and precision. Design considerations include proper material choice, process control, and tool design. In addition, designers must consider the tolerance ranges for the parts to be produced. These tolerances will differ from molder to molder, and designers should discuss their specific needs with their molders before they begin production. Designers must also consider possible revisions to the mold, such as making the part more or less tighter. Injection molding is a process in which plastic parts are formed by pressing melt into a mold. The process takes place in two stages. During the first step, the material is injected and heated, while the second stage is when the mold is opened and the part ejected. The part is then finished and ready for use.

Injection molding is a process in which plastic parts are formed by pressing melt into a mold. The process takes place in two stages. During the first step, the material is injected and heated, while the second stage is when the mold is opened and the part ejected. The part is then finished and ready for use. The cost of injection molded parts depends on many factors, including the complexity of the part and the mold design. Simpler designs, fewer CAD steps and simpler processes can help companies minimize costs. Another factor that affects the cost of injection molded parts is the geometry of the part. In general, complex geometries require more design work and tooling time. Additionally, thicker walls require more material than thin ones, which raises the cost of the part.

The cost of injection molded parts depends on many factors, including the complexity of the part and the mold design. Simpler designs, fewer CAD steps and simpler processes can help companies minimize costs. Another factor that affects the cost of injection molded parts is the geometry of the part. In general, complex geometries require more design work and tooling time. Additionally, thicker walls require more material than thin ones, which raises the cost of the part. One of the most critical design factors for injection molded parts is the wall thickness. The wall thickness affects many key characteristics of the part, from its surface finish to its structural integrity. Proper consideration of this factor can prevent costly delays due to mold issues or mold modifications. To avoid this problem, product designers must carefully consider the functional requirements of the part to determine the minimum and nominal wall thickness. In addition, they must also consider acceptable stress levels, since parts with excessively thin walls may require excessive plastic pressure and may create air traps.

One of the most critical design factors for injection molded parts is the wall thickness. The wall thickness affects many key characteristics of the part, from its surface finish to its structural integrity. Proper consideration of this factor can prevent costly delays due to mold issues or mold modifications. To avoid this problem, product designers must carefully consider the functional requirements of the part to determine the minimum and nominal wall thickness. In addition, they must also consider acceptable stress levels, since parts with excessively thin walls may require excessive plastic pressure and may create air traps. Surface finishes on injection molded parts are often used to mask defects, hide wear and tear, or enhance a product’s appearance. These finishes can also be useful when the product will come in contact with people’s hands. The surface texture you choose will depend on your desired functionality as well as the way you want to use the product. Generally, rougher textures provide better grip while masking minor molding imperfections. However, they can also make a product more difficult to release from the mold. This means that you may have to increase the draft angle of the mold. In order to get the best surface finish, the toolmaker and product designer must collaborate closely early in the design process.

Surface finishes on injection molded parts are often used to mask defects, hide wear and tear, or enhance a product’s appearance. These finishes can also be useful when the product will come in contact with people’s hands. The surface texture you choose will depend on your desired functionality as well as the way you want to use the product. Generally, rougher textures provide better grip while masking minor molding imperfections. However, they can also make a product more difficult to release from the mold. This means that you may have to increase the draft angle of the mold. In order to get the best surface finish, the toolmaker and product designer must collaborate closely early in the design process. The production volume of injection molded parts varies depending on the material being used. Large volumes of parts are expensive to produce, while small quantities can be produced for low cost. Injection molding requires a precise mold, which is CNC-machined from tool steel or aluminum. The mold has a negative of the part that is injected, a runner system, and internal water cooling channels to aid in cooling the part. Recent advances in 3D printing materials have made it possible to produce molds for low-volume injection molding. Previously, this was not financially viable due to the high cost of traditional mold making.

The production volume of injection molded parts varies depending on the material being used. Large volumes of parts are expensive to produce, while small quantities can be produced for low cost. Injection molding requires a precise mold, which is CNC-machined from tool steel or aluminum. The mold has a negative of the part that is injected, a runner system, and internal water cooling channels to aid in cooling the part. Recent advances in 3D printing materials have made it possible to produce molds for low-volume injection molding. Previously, this was not financially viable due to the high cost of traditional mold making.