Product Description

Product Description

| Product Name | Custom Precision CNC Turning Machining Aluminum Parts CNC Milling Parts from Factory Directly |

| Applicabe Material | Stainless steel, carbon steel, alloy steel, titanium, titanium alloy, aluminum, copper, brass, bronze, plastic, peek,Teflon (PTFE, F4), PPSU,PSU,PEI,POM, etc(according to customer’s requirements). |

| Surface finish | Machine finish/anodized/ beadblasting/Plating/Polish/brush/heat treatment/Brushed/Zinc plating/Nickel Plating/PVD etc. |

| Processing | CNC machining, CNC milling and turning, drilling, grinding, cutting, stamping, tapping and other related equipment. |

| Application | Medical treatment, electronics, communication security, petroleum, chemical industry, automation, light industrial machinery and other industries |

| File Format | PDF/JPEG/AI/PSD/CAD/Dwg/Step/LGS |

| Payment Terms | 50% deposit before production and 50% balance before arranging to ship. |

| Tolerance | 0.01-0.02mm or accoriding to your requirment |

| Quality control | 100%Inspection,Checking is during production process, after surface and before packing |

| Lead time | 10-15 days for sample,15-25 days for bulk order depends on your design. |

| Package | Standard package/ Pallet or container/ as per customized specifications |

| Shipment | Express & air freight is preferred / sea freight/ as per customized specifications |

| Origin | HangZhou China |

Our Advantages

1) 10 years experiences in Precision CNC machining industry

2) Advanced production and testing equipment

3) Strict implementation of international quality standards and management system

4) Mature supplier chain to create value for customers

5) Fast delivery and reasionable price

Company Profile

HangZhou Xihu (West Lake) Dis. ruijiadi hardware products factory is mainly engaged in the design and processing of precision fastening, connection and high-speed moving parts with corrosion resistance, high temperature resistance, high-voltage conductivity or insulation requirements in medical, electronic, communication and security, petroleum, chemical industry, automation light industrial machinery and other industries. It has CNC machining center, CNC walking machine, CNC lathe, CNC milling machine, automatic lathe and other related equipment.

Technical support and the best production scheme will be our greatest sincerity, and we are willing to cooperate with you for CZPT results.

Our Business:

Main Products

FAQ

Q: Are you trading company or manufacturer?

A: We are 100 % factory, we warmly welcome you to pay us a visit and see our machining capabilities here in person.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the design is simple to get machined. or it is 15-20 days if the goods are very complicated in machining structure, surely, it is according to machining difficulty and quantity.

Q: Do you provide samples ? is it free or extra?

A: Yes, we could offer the sample production before moving to mass production to test its quality. It takes the little cost of CNC Programme setting-up and surface finish, we ain’t making money from sample sometime we pay part of them for our customer since it’s the first time to work projects together .

Q:What kind of files do you accept?

A:PDF, DXF, ISG, STEP, X-T, High Resolution IPJ.

Q:What are your terms of delivery?

A:We accept EXW, FOB, CNF, etc. You can choose the most convenient one. Regarding to the shipping cost, if you have your own express account that will be welcome.

Q: What are your terms of payment?

A: 50% T/T in advance, balance before shipment.

| Application: | Fastener, Auto and Motorcycle Accessory, Machinery Accessory |

|---|---|

| Standard: | GB, EN, API650, China GB Code, JIS Code, TEMA, ASME |

| Production Type: | Batch Production |

| Machining Method: | CNC Machining |

| Material: | Nylon, Steel, Plastic, Aluminum |

| Product Type: | Non-Standard Product / Customize Product |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

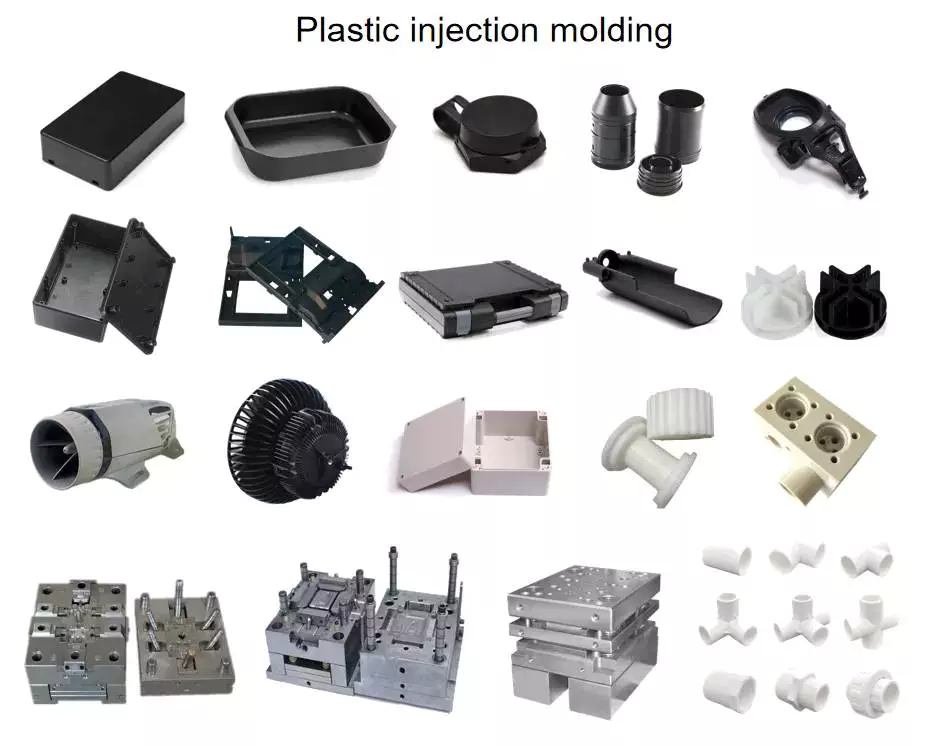

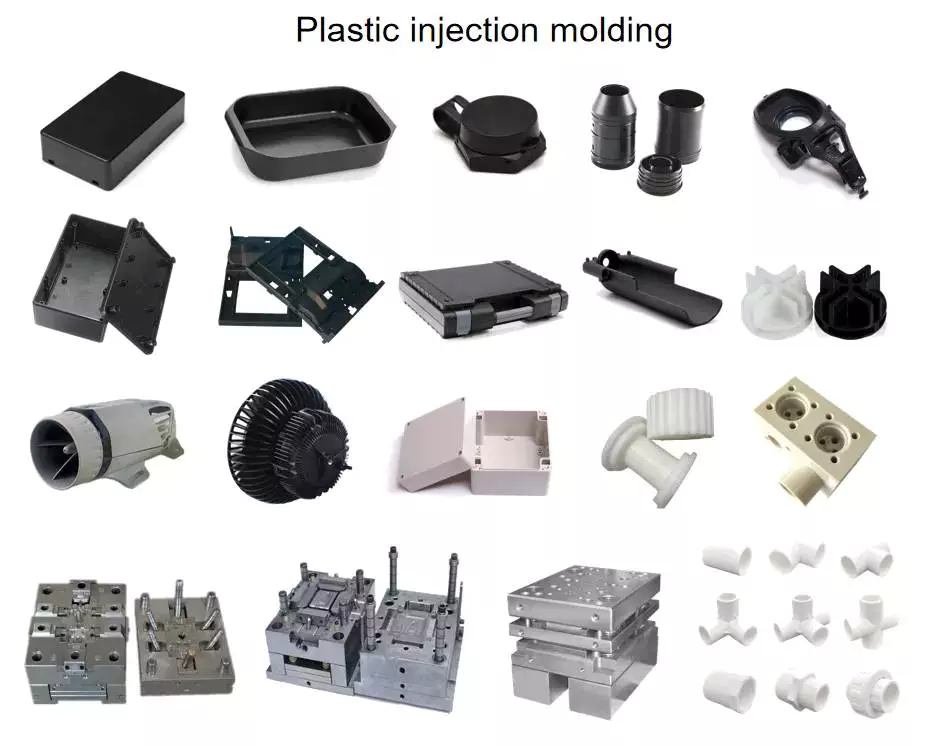

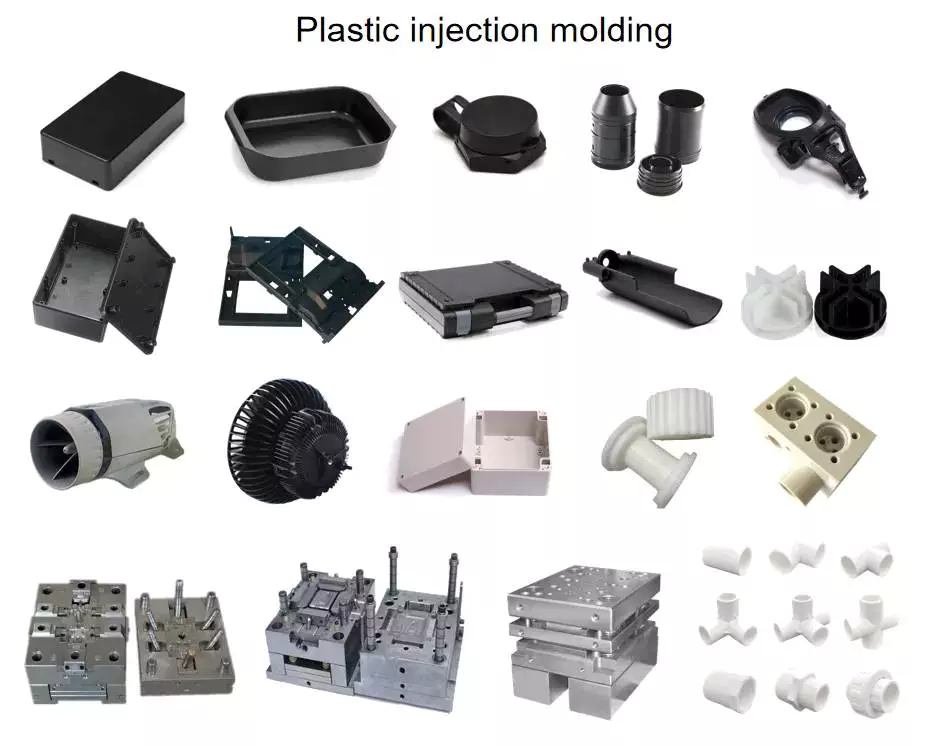

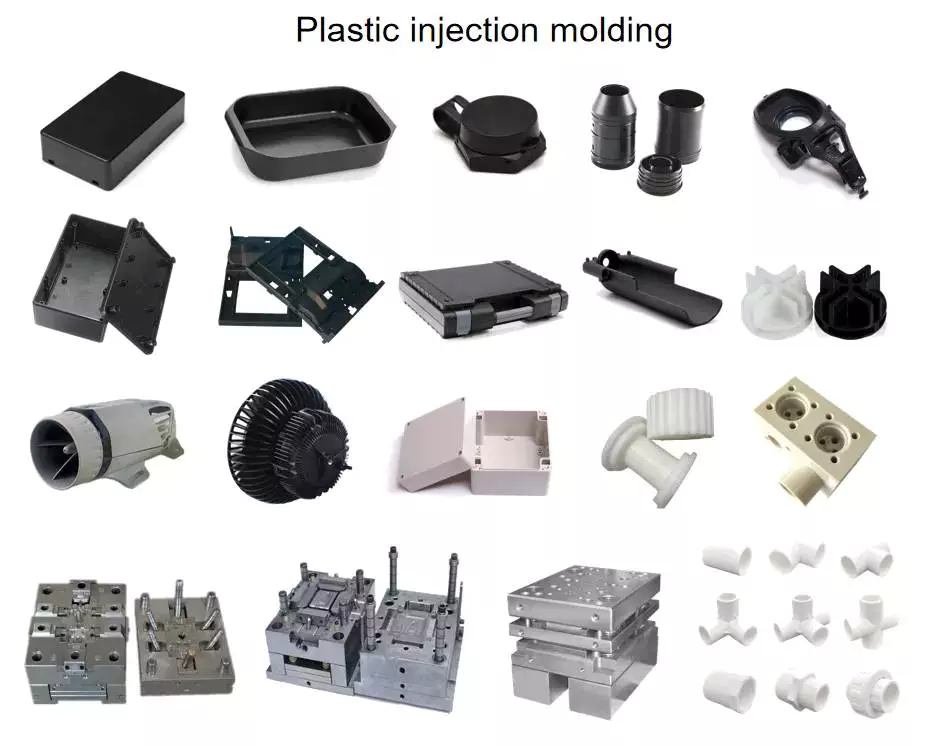

Design Considerations for Injection Molded Parts

There are many factors to consider when designing a component for injection molding. These include design factors, materials, overhangs, and process. Understanding these factors will make it easier to choose the right part for the application. In this article, we’ll go over several of the most common design considerations.

Design factors

To get the best results from your injection molded parts, you must ensure that they meet certain design factors. These factors can help you achieve consistent parts and reduce cost. These guidelines can also help you to avoid common defects. One of the most common defects is warping, which is caused by the unintended warping of the part as it cools.

When designing injection molded parts, the draft angle is critical. Increasing the draft angle allows the part to emerge cleanly from the mold and reduces stress concentration. This can improve the part’s function and speed up the production process. In addition, it ensures a uniform surface finish. Incorrect draft angles can result in parts that are not functional and can cost you money. If your product team doesn’t pay attention to these design factors, they could end up destroying expensive molds and producing a high number of rejects.

Ribs are another design factor that should be taken into consideration. Rib height should be less than three times the thickness of the part’s wall. This will prevent sink marks and minimize the chances of the ribs sticking inside the mold.

Materials

There are many options when it comes to materials for injection molded parts. Choosing the right material will affect how well it performs in your particular application. If you need a large part to be flexible and sturdy, then a plastic with good flow properties will work best. Injection molded plastics come in a variety of different resins. Choose the one that best meets your application’s needs, considering its main functionality and the desired appearance. You may also want to choose a material that is UV resistant, heat resistant, flexible, and food safe.

Polymers that are suitable for injection molding include polycarbonate and polypropylene. These materials are flexible and strong, and can be used to create parts with high-level details. These materials are also lightweight and inexpensive. Despite being flexible, they are not suitable for high-stress applications.

During the molding process, the injected material must be cooled, otherwise it will expand again. This is why you need to keep the temperature of the mould at 80 degrees Celsius or less.

Process

Injection molding is the process of creating plastic parts. The plastic is melted in a mold and then forced to cool. It then solidifies into the desired shape. During the cooling process, the plastic can shrink, so it is important to pack the material tightly in the mold to prevent visible shrinkage. When the mold is completed, it cannot be opened until the required cooling time has passed. This time can be estimated based on the thermodynamic properties of plastic and the maximum wall thickness of the part.

The mold must be precisely designed and tested. The process can be repeated many times, which makes it ideal for mass production. It is also one of the fastest ways to scale production. The more parts a mold can produce, the lower its cost per piece. This is one of the benefits of injection molding.

Injection molding parts are used for many industries, including appliances, electronics, packaging, and medical devices. They can be made to have complicated shapes.

Overhangs

Overhangs are areas of extra material that surround the surface of an injection molded part. This extra material is typically made of inexpensive material that is edged or glued on the part’s surface. The overhang material can be easily separated from the blank using a simple cutting process.

Overhangs are areas of extra material that surround the surface of an injection molded part. This extra material is typically made of inexpensive material that is edged or glued on the part’s surface. The overhang material can be easily separated from the blank using a simple cutting process.

The amount of material needed for an overhang is dependent on the shape of the part and the amount of surface area. Generally, an overhang is less than 15 percent of the cost of the part. Usually, the material used should be able to fulfill the overhang’s function and differentiate it from the material in the form flachen area.

Overhangs on injection molded parts should be avoided because they may cause the design to become unstable. To avoid this problem, consider designing your part so that the sides and edges are parallel to one another. This will help ensure that the part will be free of undercuts and overhangs.

Overhangs on injection molded parts can be avoided by ensuring that the parts are designed with tolerances in mind. For example, an overhang in an injection molded part can cause a mold to have an overhang that is too small for the machine. This can cause problems in the manufacturing process, and it can result in a costly mold.

Cost

Injection molding costs can vary depending on the complexity of the part, the size and the type of plastic. Parts with complex geometries may require additional design work and tooling. Larger parts can also cost more than small ones. The amount of time spent designing and producing them is also important.

To reduce the cost of injection molding, a manufacturer must consider two major factors: tooling and the material used. The plastic used for injection molding has several different properties, which will impact the part price. For instance, plastics with a lot of glass fibers will reduce the amount of time necessary to repair the mold. Another factor to consider is the thermal properties of the material.

The next major factor in the cost of injection molded parts is the material of the injection mold. While most of these molds are made of steel, the type and grade of steel used is important. Injection molds are also required to have nearly wear-free interior cavities. This is necessary to maintain tight tolerances.

Another factor that contributes to the cost of injection molded parts is the cost of bulk material. This material costs money and requires expensive electricity to process. Typically, the more parts you produce, the lower the cost per pound. Storage of bulk material is also a significant expense. Therefore, a quicker cycle time will reduce storage costs.

Reliability

While manufacturing involves some degree of variation, the variation should be within acceptable limits. This is essential if you want to produce high-quality, dimensionally stable parts. A reliable manufacturing process involves precise control over mold tooling and part design. It also requires repeatability in both quality and production processes.

A reliable injection molding process also focuses on detecting defects early in the production process. Invisible hazards, such as air pockets, mold materials compromised by overheating, and more, can lead to failure. These defects will most likely not be discovered by simple visual inspection and may not come to light until after warranty claims are filed from the field. By finding the defects in the early stages, manufacturers can maximize productivity and reduce costs by minimizing the number of replacement parts needed.

The process of building a custom mould for plastic components is highly skilled. A perfect mould will eliminate potential defects and ensure that the production process is reliable. Traditionally, this process relied on trial and error, which added time and money to the production process.

Design for manufacturability

When designing injection molded parts, it is imperative to keep in mind their manufacturability. Injection molding allows for complex geometries and multiple functions to be combined into a single part. For example, a hinged part can have a single mold that can produce two different halves. This also decreases the overall volume of the part.

When designing injection molded parts, it is imperative to keep in mind their manufacturability. Injection molding allows for complex geometries and multiple functions to be combined into a single part. For example, a hinged part can have a single mold that can produce two different halves. This also decreases the overall volume of the part.

Injection molded parts do not typically undergo post-processing. However, the mold itself can be finished to various degrees. If the mold is rough, it can cause friction during the ejection process and require a larger draft angle. Detailed finishing procedures are outlined by the Society of Plastics Industry.

The process of designing injection molds is very exacting. Any errors in the mold design can lead to out-of-spec parts and costly repair. Therefore, the process of Design for Manufacturability (DFM) validation is a key step early in the injection molding process. Fictiv’s DFM feedback process can identify design challenges and provide early feedback to minimize lead times and improve quality.

The surface of an injection molded part can develop sink marks, which occur when the material has not fully solidified when it is ejected from the mold. Parts with thick walls or ribs are more prone to sinking. Another common defect in plastic injection molding is drag marks, which occur when walls scrape against one another during ejection. In addition to sink marks, parts with holes or exposed edges can form knit lines.

editor by CX 2023-06-14

China Standard OEM Plastic Injection Molding Parts/Plastic Products/Plastic Parts /Auto Parts/PP/PC/PE/ABS/PVC standard tolerances for injection molded parts

Product Description

OEM Plastic Injection Molding Parts/Plastic Products/Plastic Parts /Auto Parts/PP/PC/PE/ABS/PVC

Detailed Photos

Product Parameters

|

Material |

PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, PVC, TPFE…. |

|

Color |

Depends on customer’s requirements. |

|

Support Software: |

Pro-E , UGS , SolidWorks ,AutoCAD |

|

Soft ware |

CAD/IGS /STEP/STP /PDF |

|

A surface request |

glossy ,texture |

|

Mold life |

50,000-3000,000 times |

|

Smaple : |

Free sample ! |

|

Delivery time : |

15 days production, if opening mould, plus 15-20 days. |

|

MIN Quantity: |

1000pcs |

|

Package : |

Carton and Pallet , exact part with package every pc . |

Application

Production process

Company Profile

ZheJiang (HangZhou) Xihu (West Lake) Dis.xin Metal Products Co., Ltd is specialized in the production of aluminum die casting, zinc alloy die casting, and aluminum lightweight production. Since establish of 2006, we always provide the best die casting parts to customers, and now we also develop the lightweight process successfully and obtain many national patents. Our products are widely used in automobile, medical, power Industry, electrical appliance, construction, high-speed railway and so on. And we have exported to Japan, Germany, USA, Canada, Australia and many countries.

Environmental Impact Assessment & ISO 9001 Certied

Selecting a reliable and qualified partner is more different & difficult than just choosing a supplier. We have obtained the license of EIA from government and get certied of ISO 9001, and we will always process our production per as EIA & ISO requirement strictly, to guarantee the stable production, to supply the qualified parts to you and enlarge your business finally. We sincerely hope we can become your faithful partner and develop a flouring future with you.

Certifications

Packaging & Shipping

FAQ

1.Are you a manufacturer or a trading company?

We are a 3000-square-meter factory located in ZheJiang , China.

2.How can I get a quote?

Detailed drawings(PDF/STEP/IGS/DWG…) with material, quantity and surface treatment information.

3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

4.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

5. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

6. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

7. How do you control the quality?

(1)Material inspection–Check the material surface and roughly dimension

(2) Production first inspection–To ensure the critical dimension in mass production

(3)Sampling inspection–Check the quality before sending to the warehouse

(4)Pre-shipment inspection–100% inspected by QC assistants before shipment

8. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

| Material: | Plastic |

|---|---|

| Application: | Medical, Household, Electronics, Automotive, Agricultural |

| Certification: | TS16949 |

| Name: | Plastic Injection Molded Products |

| Product: | Household Product |

| Material Available: | ABS,PC,PA,Pppmma,POM.Nylon66,,etc |

| Samples: |

US$ 3/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Designing Injection Molded Parts

Designing injection molded parts involves careful consideration of various parameters, including the wall thickness and draft angle. These factors are essential for a strong, durable part. Improper wall thickness can lead to sinking and warping defects. To avoid these issues, ensure that the walls of your injection-molded parts have a uniform thickness that does not vary too much from the rest of the part.

Designing out sharp corners in injection molded parts

When designing an injection molded part, it’s important to consider the corner radius. Sharp corners will create more stress, and this will lead to weak spots and cracks. Creating a radius around the corner helps distribute stress evenly and allows easier material flow and part ejection. Additionally, sharp corners in a mold can collect contaminants and create defects, including surface delamination.

Sharp corners in injection molded parts are a common source of stress and can cause the part to become damaged during the manufacturing process. In addition to trapping air, sharp corners may also lead to localized high temperatures that degrade the part. To reduce these risks, consider adding radii to all sharp corners.

Another important design factor to consider is wall thickness. Parts that have a smooth transition between sections should be designed with a minimum of five millimeters of wall thickness. Anything thicker will increase production cycle time and may also negatively impact mechanical properties. The use of fillets and chamfers can also help avoid these problems.

Designing out sharp corners in injection molded components can prevent costly problems from occurring during the manufacturing process. While the process is simple and straightforward, it needs to be done correctly to ensure quality. By following best practices, designers can ensure their parts won’t develop any problems or sink, warp, or voids. A poor design can also cause damage to the mold, which can cost thousands of dollars and hundreds of hours to redesign.

When designing injection molded parts, designers should consider the following guidelines. Incorporate internal and external radiuses. The internal radius (also called a fillet radius) is designed into the mold for improved quality and strength during the molding process. This radius is typically located on the inside corners or the bottom of a compartment. It can also be used for connecting walls and ribs. An external radius, on the other hand, is known as a round radius.

A right-angled part with sharp corners has a tendency to be loaded by pushing the vertical wall to the left. This creates a high-level of molded-in stress in the part. The resulting part may be weaker than expected because of the increased stress on the corner.

Importance of uniform wall thickness

Uniform wall thickness is a critical factor when designing injection-molded parts. This ensures that molten polymers can flow efficiently throughout the part. Additionally, it facilitates ideal processing. Varying wall thickness can cause problems during molding, such as air trapping, unbalanced filling, and weld lines. To ensure that your injection-molded parts are uniform, consult a plastic injection molding company that specializes in uniform wall thickness.

Injection-molded parts are more durable when the walls are uniform. A thin wall reduces the volume of material used in the part. However, thin walls can break during ejection. In addition, thin walls increase the possibility of voids. To prevent such problems, use larger machines that can produce parts with uniform wall thickness. This way, parts are easier to handle and ship.

Another important factor is the presence of gussets. These are support structures that stick out from a part’s surface. Gussets are useful for preventing warping, because they provide rigidity to thin unsupported sections. For this reason, gussets are essential when designing an injection-molded part.

Uniform wall thickness is especially critical in parts that have bends or rims. A uniform thickness helps maintain the mechanical strength and appearance of a part. However, this can be tricky as you may need to balance optical properties with mechanical ones. At Providence, we have the experience to help you navigate these challenges and produce quality parts.

Proper wall thickness is important for many reasons. It can affect both cost and production speed. The minimum wall thickness for injection molded parts depends on the part size, structural requirements, and flow behavior of the resin. Typically, injection molded parts have walls that are 2mm to 4mm thick. However, thin wall injection molding produces parts with walls as thin as 0.5mm. If you’re having trouble choosing the right wall thickness, consult an experienced injection molding company that can help you determine the appropriate wall thickness for your part.

Uneven wall thickness causes problems during injection molding. The uneven wall thickness may make the material flow through the part too quickly, or it may cause it to cool too slowly. This can lead to warping, twisting, or cracks. Even worse, uneven wall thickness can cause parts to become permanently damaged when they are ejected from the mold.

Importance of draft angle

Draft angles are an important part of design for injection molded parts. These angles are necessary because friction occurs on surfaces that come into contact with the mold during the molding process. A part with a simple geometry would only require a single degree of draft, but larger parts would need at least two degrees.

Draft angles are an important part of design for injection molded parts. These angles are necessary because friction occurs on surfaces that come into contact with the mold during the molding process. A part with a simple geometry would only require a single degree of draft, but larger parts would need at least two degrees.

Almost all parts requiring injection molding will require some amount of draft. The better the draft, the less likely the parts will have a poor finish and may bend or break. Furthermore, parts with inadequate draft will take longer to cool, extending cycle times. Moreover, if the parts are too thick or have too little draft, they may become warped.

Having a draft angle in injection molding is very important, especially if the mold has sharp corners. Without it, parts will come out scratched and will shorten the life of the mold. In some cases, parts may even not be able to eject from the mold at all. To prevent this, air needs to be allowed to get between the plastic and metal. This allows air to escape and prevents warping during ejection.

The importance of draft angle is often overlooked in the design process. Adding this angle to the mold can help prevent problems with mold release and reduce production costs. A draft angle will also allow parts to release from the mold more easily and will lead to better cosmetic finishes and fewer rejected parts. Additionally, it will reduce the need for costly elaborate ejection setups.

Draft angle should be added to the design as early as possible. It’s crucial for the success of the injection molding process, so it is best to incorporate it early in the design process. Even 3D printed parts can benefit from this detail. The size of the draft angle is also important, especially for core surfaces.

A draft angle can be large or small. The larger the draft angle, the easier it is to release the mold after the mold is completed. However, if the draft angle is too small, it can lead to scrapes on the edges or large ejector pin marks. Draft angles that are too small can lead to cracks and increase mold expenses.

Cost

There are many factors that contribute to the cost of injection-molded parts, including the material used for the mold and the complexity of the design. For example, larger parts will require a larger injection mold, which will cost more to manufacture. Additionally, more complex parts may require a mold with special features. Mold makers can advise you on how to design your part in order to reduce the overall cost of an injection-molded part.

There are many factors that contribute to the cost of injection-molded parts, including the material used for the mold and the complexity of the design. For example, larger parts will require a larger injection mold, which will cost more to manufacture. Additionally, more complex parts may require a mold with special features. Mold makers can advise you on how to design your part in order to reduce the overall cost of an injection-molded part.

One of the biggest costs related to the production of injection molded parts is the cost of the tooling. Tooling costs can reach $1,000 or more, depending on the design, materials, and finishing options. Tooling costs are less if the part quantity is small and repeatable. Higher part volumes may require a new mold and tooling.

Injection-molded parts’ cost depends on the material used and the price of procuring the material. The type of material also influences how long the part will last. Plastics that contain high percentages of glass fibers are abrasive and can damage an injection mold. Therefore, they are more expensive but may not be necessary for certain applications. Additionally, the material’s thermal properties may also affect the cycle time.

Mold size is another factor that impacts the cost. Larger molds require more CNC machinery and building space than smaller molds. Additionally, the complexity of the part will also impact the cost. Injection molds with sharp corners and complex ribs will cost more than small injection molds without intricate designs.

Injection molding is a complex process that requires a variety of moving parts. During the process, a critical piece of equipment is the injection die. This machine is a large part of the process, and comes in different sizes and shapes. Its purpose is to accept the hot plastic and machine it to extremely precise tolerances.

If your project requires a complex product with a high degree of complexity, injection molding is an excellent choice. It is ideal for initial product development, crowdfunding campaigns, and on-demand production. Mold modifications can also lower the cost of injection molding.

editor by CX 2023-06-13

China Custom Custom Molded UV Resistant CZPT UL Standard High Quality CZPT Fabrication injection molded plastic auto parts

Product Description

Item:Custom Molded UV Resistant CZPT UL Standard High Quality CZPT Fabrication

Workshop View

| Mold Material | S45C, S50C, P20, 718H, 738H, NAK80, S136, S136H |

| Mold Life Time | Life time warrange,you pay mold cost once and we will be responsible for all quality production |

| Product Material | PC, ABS,PP,PC+ABS,PA, HIPS, PVC, PE, PS, POM, Acrylic,TPE,PET,GF filled PA etc |

| Surface | Smooth, Glossy, Textured, Matte/Sandblasting |

| Color | Any Pantone or RAL color code is workable |

| Drawing Format | STEP/IGS/X_T,DWG,PDF |

| Secondary Service | Painting,Printing,Chrome Plating,Assembly etc. |

| Delivery Time | 2 to 8 weeks depending on order size |

Careful Working

Example of What We Do

Company Introduction

Q: Are you a factory or trading company ?

A: We are a factory specializing in custom plastic injection molding parts,together with rubber parts and after-treatment of CZPT such as painting,printing ,assembly etc .

Q:What info do you need if I want to get a quote for a custom plastic part ?

A: 3D drawing in IGS/STEP/X-T format is preferred .Otherwise as long as other format can provide equivellent info ,it would be fine too ,such as CAD drawing with weight info provideded ,or samples sent to us for checking .

Also please state other related info such as what quantity you need,if there are any special requirements such as painting,printing,assembly etc .

Q:What material you can handle ?

A:We can make CZPT in various kind of materials such as PC/PP/ABS/Nylon/PA6/PA66/TPE/PVC/PBT/Nylon with Glass Fiber/Polycarbonate with Glass Fiber/AS/PS etc and subber parts in NBR/Silicone etc .

Q:I have a custom plastic part to make ,I have the design but I am not familar with injection so I am not sure if this part may shrink or not working with injection,can you advise ?

A:YES,we have an engineering team who is not only familar with part design but also familar with injection feasiblity ,once we receive the drawing ,we will check the feasiblity for injection and potential problems in the design.For example,if the part is designed with unnecessary plastic which will not only add cost but also cause sink parts at the surface of the part,we will feedback you before proceeding .

Q:What colors can you do with my plastic part?

A :We can make any color that is in Pantone and RAL color system .

Q:What’s your lead time for mold and for production ?

A:Usually we can send samples in 30-35 days from mold order . Production lead time is 2 to 8 weeks depending on order size .

Q:What’s the mold life gurantee ?

A:We provide lifetime gurantee .For example,usually a mold would start to age after like 500,000 shots ,but if quantity can reach this level ,we will make a new mold at our expense to keep the stable production going on . So you pay mold cost once and we will be responsible for all production from this model .

Q:Is mold our property after we pay it in full ?

A:Yes,mold is the customer’s property after the customer pays it in full .We only keep it well in house to serve the customer’s production needs . The mold won’t be changed unless with customer’s permission .We will not produce from this mold for any third party unless we have the customer’s permission .

Q:What’s your delivery terms ?

A:It’s EXW price for air shipment and FOB HangZhou for sea shipment .HangZhou is our nearest port as we are located in HangZhou ,we can also coordinate to ship to other ports or locations if needed with negotiable price .

| Material: | PP, ABS.PC, PA, Nylon, PE, PVC, PS, POM etc |

|---|---|

| Application: | Medical, Household, Electronics, Automotive, Agricultural |

| Shaping Mode: | Injection Mould |

| Installation: | Fixed |

| Customized: | Customized |

| Mould Cavity: | Single or Mutlti Cavity |

| Customization: |

Available

| Customized Request |

|---|

Design Considerations for Injection Molded Parts

There are many factors to consider when designing a component for injection molding. These include design factors, materials, overhangs, and process. Understanding these factors will make it easier to choose the right part for the application. In this article, we’ll go over several of the most common design considerations.

Design factors

To get the best results from your injection molded parts, you must ensure that they meet certain design factors. These factors can help you achieve consistent parts and reduce cost. These guidelines can also help you to avoid common defects. One of the most common defects is warping, which is caused by the unintended warping of the part as it cools.

When designing injection molded parts, the draft angle is critical. Increasing the draft angle allows the part to emerge cleanly from the mold and reduces stress concentration. This can improve the part’s function and speed up the production process. In addition, it ensures a uniform surface finish. Incorrect draft angles can result in parts that are not functional and can cost you money. If your product team doesn’t pay attention to these design factors, they could end up destroying expensive molds and producing a high number of rejects.

Ribs are another design factor that should be taken into consideration. Rib height should be less than three times the thickness of the part’s wall. This will prevent sink marks and minimize the chances of the ribs sticking inside the mold.

Materials

There are many options when it comes to materials for injection molded parts. Choosing the right material will affect how well it performs in your particular application. If you need a large part to be flexible and sturdy, then a plastic with good flow properties will work best. Injection molded plastics come in a variety of different resins. Choose the one that best meets your application’s needs, considering its main functionality and the desired appearance. You may also want to choose a material that is UV resistant, heat resistant, flexible, and food safe.

Polymers that are suitable for injection molding include polycarbonate and polypropylene. These materials are flexible and strong, and can be used to create parts with high-level details. These materials are also lightweight and inexpensive. Despite being flexible, they are not suitable for high-stress applications.

During the molding process, the injected material must be cooled, otherwise it will expand again. This is why you need to keep the temperature of the mould at 80 degrees Celsius or less.

Process

Injection molding is the process of creating plastic parts. The plastic is melted in a mold and then forced to cool. It then solidifies into the desired shape. During the cooling process, the plastic can shrink, so it is important to pack the material tightly in the mold to prevent visible shrinkage. When the mold is completed, it cannot be opened until the required cooling time has passed. This time can be estimated based on the thermodynamic properties of plastic and the maximum wall thickness of the part.

The mold must be precisely designed and tested. The process can be repeated many times, which makes it ideal for mass production. It is also one of the fastest ways to scale production. The more parts a mold can produce, the lower its cost per piece. This is one of the benefits of injection molding.

Injection molding parts are used for many industries, including appliances, electronics, packaging, and medical devices. They can be made to have complicated shapes.

Overhangs

Overhangs are areas of extra material that surround the surface of an injection molded part. This extra material is typically made of inexpensive material that is edged or glued on the part’s surface. The overhang material can be easily separated from the blank using a simple cutting process.

Overhangs are areas of extra material that surround the surface of an injection molded part. This extra material is typically made of inexpensive material that is edged or glued on the part’s surface. The overhang material can be easily separated from the blank using a simple cutting process.

The amount of material needed for an overhang is dependent on the shape of the part and the amount of surface area. Generally, an overhang is less than 15 percent of the cost of the part. Usually, the material used should be able to fulfill the overhang’s function and differentiate it from the material in the form flachen area.

Overhangs on injection molded parts should be avoided because they may cause the design to become unstable. To avoid this problem, consider designing your part so that the sides and edges are parallel to one another. This will help ensure that the part will be free of undercuts and overhangs.

Overhangs on injection molded parts can be avoided by ensuring that the parts are designed with tolerances in mind. For example, an overhang in an injection molded part can cause a mold to have an overhang that is too small for the machine. This can cause problems in the manufacturing process, and it can result in a costly mold.

Cost

Injection molding costs can vary depending on the complexity of the part, the size and the type of plastic. Parts with complex geometries may require additional design work and tooling. Larger parts can also cost more than small ones. The amount of time spent designing and producing them is also important.

To reduce the cost of injection molding, a manufacturer must consider two major factors: tooling and the material used. The plastic used for injection molding has several different properties, which will impact the part price. For instance, plastics with a lot of glass fibers will reduce the amount of time necessary to repair the mold. Another factor to consider is the thermal properties of the material.

The next major factor in the cost of injection molded parts is the material of the injection mold. While most of these molds are made of steel, the type and grade of steel used is important. Injection molds are also required to have nearly wear-free interior cavities. This is necessary to maintain tight tolerances.

Another factor that contributes to the cost of injection molded parts is the cost of bulk material. This material costs money and requires expensive electricity to process. Typically, the more parts you produce, the lower the cost per pound. Storage of bulk material is also a significant expense. Therefore, a quicker cycle time will reduce storage costs.

Reliability

While manufacturing involves some degree of variation, the variation should be within acceptable limits. This is essential if you want to produce high-quality, dimensionally stable parts. A reliable manufacturing process involves precise control over mold tooling and part design. It also requires repeatability in both quality and production processes.

A reliable injection molding process also focuses on detecting defects early in the production process. Invisible hazards, such as air pockets, mold materials compromised by overheating, and more, can lead to failure. These defects will most likely not be discovered by simple visual inspection and may not come to light until after warranty claims are filed from the field. By finding the defects in the early stages, manufacturers can maximize productivity and reduce costs by minimizing the number of replacement parts needed.

The process of building a custom mould for plastic components is highly skilled. A perfect mould will eliminate potential defects and ensure that the production process is reliable. Traditionally, this process relied on trial and error, which added time and money to the production process.

Design for manufacturability

When designing injection molded parts, it is imperative to keep in mind their manufacturability. Injection molding allows for complex geometries and multiple functions to be combined into a single part. For example, a hinged part can have a single mold that can produce two different halves. This also decreases the overall volume of the part.

When designing injection molded parts, it is imperative to keep in mind their manufacturability. Injection molding allows for complex geometries and multiple functions to be combined into a single part. For example, a hinged part can have a single mold that can produce two different halves. This also decreases the overall volume of the part.

Injection molded parts do not typically undergo post-processing. However, the mold itself can be finished to various degrees. If the mold is rough, it can cause friction during the ejection process and require a larger draft angle. Detailed finishing procedures are outlined by the Society of Plastics Industry.

The process of designing injection molds is very exacting. Any errors in the mold design can lead to out-of-spec parts and costly repair. Therefore, the process of Design for Manufacturability (DFM) validation is a key step early in the injection molding process. Fictiv’s DFM feedback process can identify design challenges and provide early feedback to minimize lead times and improve quality.

The surface of an injection molded part can develop sink marks, which occur when the material has not fully solidified when it is ejected from the mold. Parts with thick walls or ribs are more prone to sinking. Another common defect in plastic injection molding is drag marks, which occur when walls scrape against one another during ejection. In addition to sink marks, parts with holes or exposed edges can form knit lines.

editor by CX 2023-06-12

China supplier From 3D/Sample to Actual Part Custom Injection Molding PA6/PBT with Glass Fiber Components joining injection molded parts

Product Description

Item:China Plastic Injection Molding Manufacturer OEM Made per Drawing or Sample Glass Fiber Filled Nylon/PBT Plastic Parts

Workshop View

| Mold Material | S45C, S50C, P20, 718H, 738H, NAK80, S136, S136H |

| Mold Life Time | Life time warrange,you pay mold cost once and we will be responsible for all quality production |

| Product Material | PC, ABS,PP,PC+ABS,PA, HIPS, PVC, PE, PS, POM, Acrylic,TPE,PET,GF filled PA etc |

| Surface | Smooth, Glossy, Textured, Matte/Sandblasting |

| Color | Any Pantone or RAL color code is workable |

| Drawing Format | STEP/IGS/X_T,DWG,PDF |

| Secondary Service | Painting,Printing,Chrome Plating,Assembly etc. |

| Delivery Time | 2 to 8 weeks depending on order size |

Careful Working

Example of What We Do

Company Introduction

Q: Are you a factory or trading company ?

A: We are a factory specializing in custom plastic injection molding parts,together with rubber parts and after-treatment of CZPT such as painting,printing ,assembly etc .

Q:What info do you need if I want to get a quote for a custom plastic part ?

A: 3D drawing in IGS/STEP/X-T format is preferred .Otherwise as long as other format can provide equivellent info ,it would be fine too ,such as CAD drawing with weight info provideded ,or samples sent to us for checking .

Also please state other related info such as what quantity you need,if there are any special requirements such as painting,printing,assembly etc .

Q:What material you can handle ?

A:We can make CZPT in various kind of materials such as PC/PP/ABS/Nylon/PA6/PA66/TPE/PVC/PBT/Nylon with Glass Fiber/Polycarbonate with Glass Fiber/AS/PS etc and subber parts in NBR/Silicone etc .

Q:I have a custom plastic part to make ,I have the design but I am not familar with injection so I am not sure if this part may shrink or not working with injection,can you advise ?

A:YES,we have an engineering team who is not only familar with part design but also familar with injection feasiblity ,once we receive the drawing ,we will check the feasiblity for injection and potential problems in the design.For example,if the part is designed with unnecessary plastic which will not only add cost but also cause sink parts at the surface of the part,we will feedback you before proceeding .

Q:What colors can you do with my plastic part?

A :We can make any color that is in Pantone and RAL color system .

Q:What’s your lead time for mold and for production ?

A:Usually we can send samples in 30-35 days from mold order . Production lead time is 2 to 8 weeks depending on order size .

Q:What’s the mold life gurantee ?

A:We provide lifetime gurantee .For example,usually a mold would start to age after like 500,000 shots ,but if quantity can reach this level ,we will make a new mold at our expense to keep the stable production going on . So you pay mold cost once and we will be responsible for all production from this model .

Q:Is mold our property after we pay it in full ?

A:Yes,mold is the customer’s property after the customer pays it in full .We only keep it well in house to serve the customer’s production needs . The mold won’t be changed unless with customer’s permission .We will not produce from this mold for any third party unless we have the customer’s permission .

Q:What’s your delivery terms ?

A:It’s EXW price for air shipment and FOB HangZhou for sea shipment .HangZhou is our nearest port as we are located in HangZhou ,we can also coordinate to ship to other ports or locations if needed with negotiable price .

| Material: | PP, ABS.PC, PA, Nylon, PE, PVC, PS, POM etc |

|---|---|

| Application: | Medical, Household, Electronics, Automotive, Agricultural |

| Shaping Mode: | Injection Mould |

| Installation: | Fixed |

| Customized: | Customized |

| Mould Cavity: | Single or Mutlti Cavity |

| Customization: |

Available

| Customized Request |

|---|

Advantages of Injection Moulding

Whether you’re considering an injection molded part for your next project or need to replace an existing one, there are a few factors you should consider. These include design, surface finishes, tooling costs, and material compatibility. Understanding these factors can help you make the right decision. Read on to learn more about the advantages of injection molding and how to get started.

Design factors

One of the most critical design factors for injection molded parts is the wall thickness. The wall thickness affects many key characteristics of the part, from its surface finish to its structural integrity. Proper consideration of this factor can prevent costly delays due to mold issues or mold modifications. To avoid this problem, product designers must carefully consider the functional requirements of the part to determine the minimum and nominal wall thickness. In addition, they must also consider acceptable stress levels, since parts with excessively thin walls may require excessive plastic pressure and may create air traps.

Another factor to consider when designing a part is its ejection and release capabilities. If the part is released from the mold, the tools should be able to slide the plastic out. Injection molds usually have two sides, one of which is ejectable, and another that remains in the mold. In some cases, special features are required to prevent part release, such as a ramp or a gusset. These design features can increase the design flexibility, but they can also increase the cost of the mold.

When designing injection molded parts, the engineering team first determines the key design elements. These elements will make sure the injection process goes as smoothly as possible. This includes factors like wall thickness, rib design, boss design, corner transition, and weld line, among others. The engineering team will then perform a design for manufacturability analysis and, if all is well, can start building and testing the mold.

Material compatibility

Several factors can affect material compatibility of injection molded parts. When molding plastic parts, it is important to choose a material that is compatible with the part’s intended purpose. Many injection molding processes require that the two main plastic materials used are compatible with each other. This is the case in overmolding and two-shot injection molding.

The material you use to make an injection molded part will significantly impact the tolerance of the finished product. This is why material selection is as important as the design of the part. Many types of plastic resins can be used for injection molding. In addition, many of these resins can be modified or strengthened by adding additives, fillers, and stabilizers. This flexibility allows product teams to tailor the material to achieve desired performance characteristics.

One of the most common thermoplastics is polypropylene. It is extremely durable and has good impact strength and moisture resistance. This material is also recyclable and does not react with food.

Tooling costs

One of the largest costs for manufacturing injection molded parts is tooling. For an OEM, tooling costs can range from $15K per part for a simple part to $500K for a mold with complex geometry. Tooling costs vary based on the type of steel used and the production volume of the part.

To get a reasonable estimate, companies should have a final design, preliminary design, and sample part to hand when requesting quotes. The dimensions and complexity of the cavity in a mold are crucial in determining the tooling cost, as are the part tolerances. Part tolerances are based on the area covered by the part and its functions within the mold.

The type of mold you need can also impact your tooling costs. Injection molding machines can accommodate many different kinds of molds. Some molds are made from a single mold, while others require multiple molds. Some molds can be complicated, making them unmanufacturable, which in turn drives up the cost of tooling.

The costs for tooling for injection molding are not well known, but they do add up quickly. Many product development teams tend to consider the cost of the injection molding process in terms of direct materials, machine time, and labor, but that cost model often fails to take into account additional components.

Surface finishes

Surface finishes on injection molded parts are often used to mask defects, hide wear and tear, or enhance a product’s appearance. These finishes can also be useful when the product will come in contact with people’s hands. The surface texture you choose will depend on your desired functionality as well as the way you want to use the product. Generally, rougher textures provide better grip while masking minor molding imperfections. However, they can also make a product more difficult to release from the mold. This means that you may have to increase the draft angle of the mold. In order to get the best surface finish, the toolmaker and product designer must collaborate closely early in the design process.

Surface finishes on injection molded parts are often used to mask defects, hide wear and tear, or enhance a product’s appearance. These finishes can also be useful when the product will come in contact with people’s hands. The surface texture you choose will depend on your desired functionality as well as the way you want to use the product. Generally, rougher textures provide better grip while masking minor molding imperfections. However, they can also make a product more difficult to release from the mold. This means that you may have to increase the draft angle of the mold. In order to get the best surface finish, the toolmaker and product designer must collaborate closely early in the design process.

There are several different surface finishes that can be used for injection molded parts. One type is known as the B-grade finish, and is compatible with a wide variety of injection molding plastics. Another type of finish is called a stone polishing process, and is ideal for parts that have no aesthetic value.

Overhangs

The injection moulding industry refers to overhangs on injection molded parts as “undercuts,” and these can lead to design instability. To minimize undercuts, the design must be parallel to the part’s surface. If an undercut is present, a zigzag parting line can be used.

The overhang is typically a few millimeters shorter than the surface of the mold. It is generally made from a lower-cost plastic material than the part’s surface area. The material used for the overhang should have sufficient strength to fulfill its function. An overhang will also help to prevent the piece from deforming or cracking.

Injection molding can create overhangs around the perimeter of a part. Overhangs are not always necessary; they can be added to parts as desired. Adding an overhang, however, will add substantial tooling costs. As a result, it is better to minimize the overall thickness of a design. However, in some cases an overhang can be useful to make the part look more attractive.

For parts with complex geometries, there are a few options for overhangs. Some manufacturers use side-action molds to form more complex shapes.

CNC machining

CNC machining of injection molded parts is a process that helps manufacturers achieve precise surfaces and shapes for their products. This process typically begins with the milling of the tooling, which is typically made of aluminum or steel. This tooling is then placed in a CNC mill. This machine carves the negative of the final plastic part, making it possible to achieve specific surface finishes. The process can be adapted to create a part with a complex structure or special features.

CNC machining allows the manufacturer to produce high-performance parts. This is possible because MIM parts do not experience induced stresses or internal pressure during the manufacturing process. Furthermore, the parts produced by MIM are more durable than CNC parts. Despite their advantages, CNC machining has its limitations, especially when it comes to design freedom and intricacy. This factor is largely dependent on the software used by the manufacturer or designer.

One drawback of CNC machining is its higher cost. Compared to injection molding, CNC machining is more expensive per part. The reason is that the initial mold cost is relatively high and is spread over a large number of parts. Once the injection molding process has been completed, the cost of the parts produced by this process becomes more competitive with those produced by machined parts. However, the cost gap increases with the volume of parts produced. This cost crossover generally occurs in quantities of at least 100 parts and can reach a maximum of 5000 parts.

Production volume

The production volume of injection molded parts varies depending on the material being used. Large volumes of parts are expensive to produce, while small quantities can be produced for low cost. Injection molding requires a precise mold, which is CNC-machined from tool steel or aluminum. The mold has a negative of the part that is injected, a runner system, and internal water cooling channels to aid in cooling the part. Recent advances in 3D printing materials have made it possible to produce molds for low-volume injection molding. Previously, this was not financially viable due to the high cost of traditional mold making.

The production volume of injection molded parts varies depending on the material being used. Large volumes of parts are expensive to produce, while small quantities can be produced for low cost. Injection molding requires a precise mold, which is CNC-machined from tool steel or aluminum. The mold has a negative of the part that is injected, a runner system, and internal water cooling channels to aid in cooling the part. Recent advances in 3D printing materials have made it possible to produce molds for low-volume injection molding. Previously, this was not financially viable due to the high cost of traditional mold making.

A mold is used to produce plastic parts. The molding process is very fast, with each cycle taking anywhere from 30 seconds to 90 seconds. After a part is molded, it is removed from the mold and placed on a holding container or conveyor belt. Injection molded parts are generally ready for use right away and require minimal post-processing. Injection molded parts have a similar design to a photograph, since the geometry is directly transferred to the part’s surface texture.

When selecting a plastic mold, it is important to determine the volume that the part will be produced at. If the volume is low, softer plastics may be used. However, as the part is molded over, its performance characteristics may degrade. In low-volume production, it is important to consider the overall complexity of the part. This includes the part’s draft, wall thickness, and surface finish.

editor by CX 2023-06-09

China supplier From 3D/Sample to Actual Part Custom Injection Molding PA6/PBT with Glass Fiber Components wholesaler

Product Description

Item:China Plastic Injection Molding Manufacturer OEM Made per Drawing or Sample Glass Fiber Filled Nylon/PBT Plastic Parts

Workshop View

| Mold Material | S45C, S50C, P20, 718H, 738H, NAK80, S136, S136H |

| Mold Life Time | Life time warrange,you pay mold cost once and we will be responsible for all quality production |

| Product Material | PC, ABS,PP,PC+ABS,PA, HIPS, PVC, PE, PS, POM, Acrylic,TPE,PET,GF filled PA etc |

| Surface | Smooth, Glossy, Textured, Matte/Sandblasting |

| Color | Any Pantone or RAL color code is workable |

| Drawing Format | STEP/IGS/X_T,DWG,PDF |

| Secondary Service | Painting,Printing,Chrome Plating,Assembly etc. |

| Delivery Time | 2 to 8 weeks depending on order size |

Careful Working

Example of What We Do

Company Introduction

Q: Are you a factory or trading company ?

A: We are a factory specializing in custom plastic injection molding parts,together with rubber parts and after-treatment of CZPT such as painting,printing ,assembly etc .

Q:What info do you need if I want to get a quote for a custom plastic part ?

A: 3D drawing in IGS/STEP/X-T format is preferred .Otherwise as long as other format can provide equivellent info ,it would be fine too ,such as CAD drawing with weight info provideded ,or samples sent to us for checking .

Also please state other related info such as what quantity you need,if there are any special requirements such as painting,printing,assembly etc .

Q:What material you can handle ?

A:We can make CZPT in various kind of materials such as PC/PP/ABS/Nylon/PA6/PA66/TPE/PVC/PBT/Nylon with Glass Fiber/Polycarbonate with Glass Fiber/AS/PS etc and subber parts in NBR/Silicone etc .

Q:I have a custom plastic part to make ,I have the design but I am not familar with injection so I am not sure if this part may shrink or not working with injection,can you advise ?

A:YES,we have an engineering team who is not only familar with part design but also familar with injection feasiblity ,once we receive the drawing ,we will check the feasiblity for injection and potential problems in the design.For example,if the part is designed with unnecessary plastic which will not only add cost but also cause sink parts at the surface of the part,we will feedback you before proceeding .

Q:What colors can you do with my plastic part?

A :We can make any color that is in Pantone and RAL color system .

Q:What’s your lead time for mold and for production ?

A:Usually we can send samples in 30-35 days from mold order . Production lead time is 2 to 8 weeks depending on order size .

Q:What’s the mold life gurantee ?

A:We provide lifetime gurantee .For example,usually a mold would start to age after like 500,000 shots ,but if quantity can reach this level ,we will make a new mold at our expense to keep the stable production going on . So you pay mold cost once and we will be responsible for all production from this model .

Q:Is mold our property after we pay it in full ?

A:Yes,mold is the customer’s property after the customer pays it in full .We only keep it well in house to serve the customer’s production needs . The mold won’t be changed unless with customer’s permission .We will not produce from this mold for any third party unless we have the customer’s permission .

Q:What’s your delivery terms ?

A:It’s EXW price for air shipment and FOB HangZhou for sea shipment .HangZhou is our nearest port as we are located in HangZhou ,we can also coordinate to ship to other ports or locations if needed with negotiable price .

| Material: | PP, ABS.PC, PA, Nylon, PE, PVC, PS, POM etc |

|---|---|

| Application: | Medical, Household, Electronics, Automotive, Agricultural |

| Shaping Mode: | Injection Mould |

| Installation: | Fixed |

| Customized: | Customized |

| Mould Cavity: | Single or Mutlti Cavity |

| Customization: |

Available

| Customized Request |

|---|

What Is Injection Moulding?

Injection molding is a process of producing precision-molded parts by fusing raw plastics and guiding them into a mold. The main components of an injection mold are a hopper, barrel, and reciprocating screw. Before injection, the raw plastics are mixed with coloring pigments and reinforcing additives.

Characteristics of injection molded parts

Injection molding is the process of manufacturing plastic parts. It uses thermoplastic, thermoset, or elastomers to manufacture components. The range of materials is enormous and includes tens of thousands of different polymers. They are blended with other materials and alloys to produce a wide range of properties. Designers select the appropriate materials for the job based on the properties and functions desired in the finished part. During the mold design process, mold materials must be carefully chosen, as different materials require different molding parameters.

Injection molding requires precise tolerances of the temperature and strain levels. The maximum strain level is about 0.15 percent. It is possible to adjust these parameters to meet the requirements of an injection molding project. The resulting products can be easily checked for quality by measuring the strain and temperature of the mold inserts in real time.

Injection molding is known for its laminar flow of the polymer. However, there is still a possibility for side-to-side thermal variations in the part forming cavity. This is illustrated in FIG. 4. The part has high and low sheared areas; the higher sheared areas flow on the bottom side of the part, while the lower sheared areas flow on the top side.

Injection molding is used to make many different types of plastic parts, from small parts to entire body panels of a car. These parts can be made from a variety of different materials, such as polypropylene for toys and ABS for consumer electronics. They can also be made from metal, such as aluminum or steel.

The melting temperature of plastic parts must be appropriate for the project’s specifications. The mold should be large enough to produce the parts desired. This will minimize the impact of uneven shrinkage on the product’s dimensional accuracy. In addition to the temperature, a mold must be designed with the material’s properties in mind.

Tooling fabrication

Injection molded parts are produced using molds. This process is a complex process that requires customization to ensure proper fit and function. The main component of a mold is the base, which holds the cavities, ejectors and cooling lines. The size and position of these components are crucial to the production of quality parts. Incorrectly sized vents can cause trapped air to enter the part during the molding process. This can lead to gas bubbles, burn marks, and poor part quality.

Injection molded parts are produced using molds. This process is a complex process that requires customization to ensure proper fit and function. The main component of a mold is the base, which holds the cavities, ejectors and cooling lines. The size and position of these components are crucial to the production of quality parts. Incorrectly sized vents can cause trapped air to enter the part during the molding process. This can lead to gas bubbles, burn marks, and poor part quality.

The material used for tooling fabrication is usually H-13 tool steel. This steel is suitable for injection molded parts as it has a low elongation value. The material used to fabricate tooling for injection molded parts typically has a high yield strength. The material used for injection moulding tooling is typically 420 stainless steel or H-13 tool steel. These materials are suitable for most injection molding processes and have comparable yield strength compared to wrought or MIM parts.

Another important part of tooling fabrication is the design of the mold. It is important to design the mold with a draft angle, as this will make ejection easier and reduce costs. A draft angle of 5o is recommended when designing a tall feature. Choosing a draft angle is essential to ensuring that the plastic part is free from air bubbles after injection molding.

Injection moulding tooling costs can account for as much as 15% of the cost of an injection moulded part. With innovation in mould materials and design, tooling fabrication can be more efficient and cost-effective.

Surface finishes on injection molded parts

Surface finishes on injection molded parts can have a variety of effects on the part’s appearance and performance. Different materials lend themselves to different kinds of surface finishes, with some plastics better suited for smooth, glossy finishes than others. The type of surface finish is also affected by several factors, including the speed of injection and the melt temperature. Faster injection speeds help improve the quality of plastic finishes by decreasing the visibility of weld lines and improving the overall appearance of the parts.

Surface finishes on injection molded parts can have a variety of effects on the part’s appearance and performance. Different materials lend themselves to different kinds of surface finishes, with some plastics better suited for smooth, glossy finishes than others. The type of surface finish is also affected by several factors, including the speed of injection and the melt temperature. Faster injection speeds help improve the quality of plastic finishes by decreasing the visibility of weld lines and improving the overall appearance of the parts.

For a smooth plastic surface finish, some companies require a high level of roughness on the part. Others may prefer a more rough look, but both options can have their benefits. The type of surface finish chosen will depend on the part’s purpose and intended application. For example, a glossy plastic finish may be preferred for a cosmetic part, while a rougher finish may be better suited for a mechanical part that must be tough and cost-effective.

Surface finishes on injection molded parts are often customized to match the application. For example, some parts require a rough surface finish because they require a greater amount of friction. These parts may require a sandblasting process to achieve the desired texture. Other processes can also be used to control plastic texture.

The type of surface finish depends on the materials used, as well as the design and shape of the part. The type of material used, additives, and temperature also have an impact on the surface finish. It is also important to consider surface finishes early in the design process.

Importance of a secondary operation to improve accuracy

While most injection molded parts do not require secondary operations, some components do require this type of processing. The surface finish of a component will determine how well it functions and what other secondary operations are necessary. Depending on the part’s function, a smooth or textured surface may be appropriate. Additionally, some parts may require surface preparation before applying adhesives, so an accurate surface finish can make all the difference. In order to achieve the desired finish, the injection molder should have experience molding different materials. He or she should also have the knowledge of how to simulate the flow of a mold. Also, experienced molders know how to mix materials to achieve the desired color, avoiding the need for secondary painting processes.

Injection molding is a complex process that requires precision and accuracy. The optimal temperature of the melted plastic must be chosen, as well as the mold itself. The mold must also be designed for the correct flow of plastic. In addition, it must be made of the best thermoplastic material for the part’s design. Finally, the correct time must be allowed for the part to be solid before it is ejected. Many of these issues can be overcome with specialized tooling that is customized to the part’s design.

Injection molding offers the opportunity to make complex parts at low cost. It also allows manufacturers to make parts with complicated geometries and multiple functions.

editor by CX 2023-06-08

China best Injection Molded Parts for Automobile Parts automotive injection molded parts

Product Description

Packaging & Delivery

Packaging Details

For Mold

After assembling mold, we paint anti-rust fog or grease on mold, then cover it with thin film and place it into a stable wooden

box.

For Product

To wrap each part up with semi-transparent thin foam and put it into plastic bag first, and then place the products into cartons with thin sponge plates to prevent scratches. Or as per customer’s request.

|

Plastic Materials: |

Rubber, Slilconce rubber, LSR,Aluminum, Zinc,Copper…Metal…etc. |

|

Other materials: |

PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,…etc. |

|

Standard: |

ISO9001:2008 |

|

Quality: |

RoSH and SGS standard |

|

Feature: |

Non marking and Non flash |

|

Color,Quantity,Unit price,Tooling cost,Tooling size: |

According to your 2D, 3D Drawing |

|

Package: |

Standard exported Wooden box packed, Fumigation process(upon required) |

|

Mold Building Lead Time: |

T1, 4-5 weeks, Part measurement report (upon required). |

|

Export Country: |

Europe, Japan, America, Australian, UK, Canada, France, Germany, Italy…etc.: |

|

Experience: |

13 years experience in plastic injection mold making and plastic prouducts produce. |

|

To be discussed |

In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, |

| Shaping Mode: | Injection Mould |

|---|---|

| Surface Finish Process: | Polishing |

| Mould Cavity: | Single Cavity |

| Plastic Material: | TPE |

| Process Combination Type: | Single-Process Mode |

| Customization: |

Available

| Customized Request |

|---|

Injection Molded Parts – Design Considerations

If you want to produce high-quality Injection molded parts, there are several factors to consider before the design process. These factors include the Surface finish, Material compatibility, and Tooling fabrication. This article will focus on some of these factors. Ultimately, you can save time and money by designing the parts in-house.

Design considerations

When creating a new part, or updating an existing part, design considerations for injection molded parts are critical. The decisions you make in these early stages of development can have a profound effect on the final product, and they can also have substantial cost and timing implications. In this guide, we’ll explore key design considerations, including how to maximize the efficiency of the injection molding process. We’ll also touch on how to optimize gate placement and parting lines.

To ensure a successful injection molding process, part design must balance structural integrity and plastic fill volume. This means creating parts with relatively thin walls that have adequate support and avoid warping or sinking. To do this, injection molded parts often feature ribs or projections to strengthen the walls. However, too thin of a wall can result in excessive plastic pressure and air traps.

One of the most important design considerations for injection molded parts is the direction of the parting line. For many applications, a parting line is obvious, but for others it’s a little less obvious. The first step in designing an injection mold is to determine which direction it should open.

Another critical design consideration is the part’s ejection. If a part isn’t ejected properly, it will stick to the mold. A part that has too many undercuts or ribs will end up stuck on the mold’s side, making it difficult to eject it from the mold. A part that has a draft angle of at least five degrees is much easier to eject.

Another important design consideration for an injection molded part is the type of plastic used. Some plastics do not tolerate undercuts. However, some materials are able to tolerate undercuts of up to five percent. Undercuts are not ideal and can increase the complexity and cost of the injection mold.

Another design consideration for injection molded parts is the radius of edges. Sharp corners can create high molded-in stresses and can lead to failure points. A radius eliminates this stress by redistributing the stress more evenly throughout the part. This also facilitates flow of the material through the mold.

Surface finish

Injection molded parts are often finished with additional processing in order to improve their aesthetic quality. There are a variety of finishing processes, including machining and sanding, which give injected molded parts a particular look, feel, or texture. The surface finish of a plastic part affects both its aesthetics and its functionality. According to the Society of Plastics Industry, certain standards for surface finish are essential to the aesthetics and durability of plastic parts.

Surface finish of injection molded parts depends on the primary design goal. For instance, some designs may need a part to be aesthetically pleasing while others may want to enhance its functionality. Surface texture is often used by designers and engineers to achieve different aesthetic goals, such as improving the product’s perceived value. A textured surface may also help hide imperfections and improve the part’s non-slip qualities.

Surface finish is a critical aspect of plastic injection molding. It can affect material selection, tooling, and other process decisions. It is important to determine the desired surface finish early in the design phase. A skilled plastic injection molder can assist you in making this decision. In addition to determining the finish you need, a skilled molder can help you decide the best material for the job.

The PIA classification system defines four basic grades for surface finish. There are subcategories for each grade. Group A surface finish is smooth, and grade B and C finishes are textured. The former is the most common and economical finish and is most suitable for industrial parts. It can hide deformations and tooling marks, and is the least expensive finish type.

Surface finish of injection molded parts can vary greatly, and can be crucial to the performance and appearance of the part. Some companies prefer plastic parts with a glossy finish, while others prefer a textured surface for aesthetic reasons. While the former may be better for aesthetic purposes, rougher surfaces are often preferred for functional or mechanical parts.

Material compatibility

Material compatibility is important for the durability of your injection molded parts. You can use multiple materials in the same part by mixing resins. This is an ideal solution for parts that require adhesion, friction, or wear. Fast Radius can simplify the material selection process, optimize part design, and speed up production.

Material compatibility is important for the durability of your injection molded parts. You can use multiple materials in the same part by mixing resins. This is an ideal solution for parts that require adhesion, friction, or wear. Fast Radius can simplify the material selection process, optimize part design, and speed up production.

ABS is a thermoplastic polymer that can withstand a range of temperatures. Its low melting point means that it is easy to mold, and it has good chemical and moisture resistance. ABS also has good impact strength, and is highly durable. It is easy to recycle. Nylon is another versatile material for injection molding. It can be used for car tires, electrical components, and various apparel.

When choosing the material for your injection molded parts, keep in mind that the type of resin will determine their tolerance. Injection molding is compatible with a wide range of plastic resins. Some materials are more suitable than others for certain applications, and many plastics can be modified with stabilizers or additives to improve their properties. This flexibility allows the product development team to customize materials to achieve the performance characteristics they desire.

Polyamides are another great option for injection molding parts. Both natural and synthetic varieties of these plastics have excellent properties. However, they have some drawbacks. For instance, nylon injection molding is difficult and can result in inadequate filling. However, Nylon injection molding has many benefits, including high impact resistance and heat resistance.

Polybutylene terephthalate (PBT) is a high-molecular-weight polymer with excellent mechanical and chemical resistance. It is a good choice for components in the medical, automotive, and lighting industries. Its low water absorption and low flammability make it suitable for many applications.