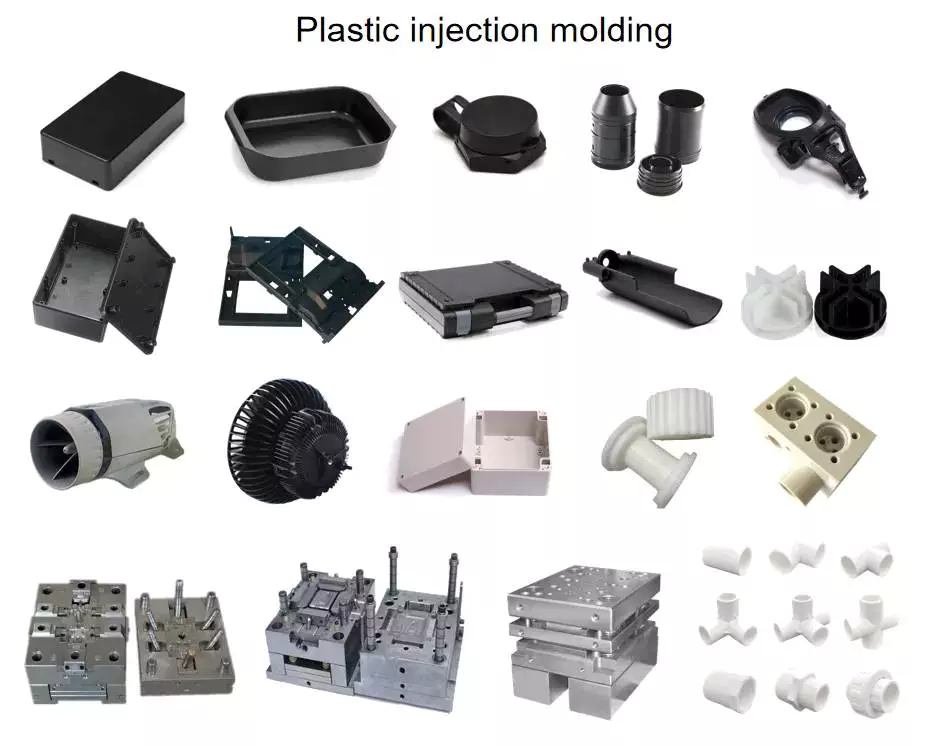

Product Description

Custom Molded PP/PC/PE/ABS/PVC/PS/POM/Nylon Plastic Auto Parts Injection

Detailed Photos

Related Products

Main Processes

Main Materials

| Aluminum Alloy | ZL101, ZL101A, ZL102, ZL104, ZL108, ZL118, ZL203, ADC5, ADC6, ADC10, ADC12, A356, A356.2, A380, A383, A360, A535, A319, A369, AlSi7Mg, AlSi9Mg, AlSi10Mg, AlSi12 |

| Zinc Alloy | Zamark 3, Zamark 4, Zamark 5, Zamark 6, 7, 8 |

| Forging & Profile Aluminum | 6061, 6063, 6082, 7075 |

| OEM Materials | HT200, HT250, HT300 QT450, QT500, QT600, QT700 |

| Q195, Q235, Q345 (Q355), SPCC, SPEC, DC04, DC01, 15#, 18#, 20#, 30#, 35#, 45#, 50# 20Mn, 20Cr, 20CrNi, 30Cr, 35CrMo, 40CrMo, 42CrMo |

|

| 201, 303, 304, 316, 316L | |

| POM, PP, PC, ABS, ASA, PA6, PA66 |

Squeeze Casting

Squeeze Casting as liquid-metal forging, is a process by which molten metal solidifies under pressure within closed dies positioned between the plates of a hydraulic press.The applied pressure and instant contact of the molten metal with the die surface produce a rapid heat transfer condition that yields a pore-free fine-grain casting with mechanical properties approaching those of a wrought product. The squeeze casting process is easily automated to produce near-net to net shape high-quality components.

Main Materials:

A356,A356.2,A319S,AlSi9Mg, ZL104, ZL118

Advantage:

1) Good roughness like die casting & precision casting;

2) Parts with high-accuracy and tolerance like die casting & precision casting;

3) No more material costs and extra machining, much better than forging;

4) Can be T6 treatment, better than die casting, and like forging;

5) Parts with High Sealing Property as with almost no pores;

6) High mechanical property like forging, better than investment casting or sand casting;

Company Profile

ZheJiang (HangZhou) Xihu (West Lake) Dis.xin Metal Products Co.,Ltd is specialized in the production of aluminum die casting, zinc alloy die casting, and aluminum lightweight production. With 15+years experience, we always provide the best die casting parts to customers, and now we also develop the lightweight process successfully and obtain many national patents.

Our products are widely used in automobile, medical, power Industry, electrical appliance, construction, high-speed railway and so on. And we have exported to Japan, Germany, USA, Canada, Australia and many countries.

Great advantages as a manufacturer:

Firstly, we have fixed material partner supplying us the good quality original material and assistant us to research & develop new material.

Secondly, we have our own design and production team of moulds/tooling, which is very cost-effective for moulds/tooling change or optimize.

Finally we can offer Supply Chain Service with time & costs saved from design, casting, precision CNC machining, finishing to the final assembled products with shipment service to you. About our capacity we could make 6000tons at least every year, and make the parts from 0.005kg~15kg according to your drawings and samples.

FAQ

Q.1:Can we get your free samples?

A. For the samples in our stocksize, sure, we’d love to provide you for free to test the quality, but hope you can bear the Freight cost.

B. For the customized samples, we can also open a new mould as your requests, but hope you can bear this samples cost.

Q.2:What is the normal lead time?

A. For stock products, we will send goods to you within 1~7days after receiving your payment.

B. For mass production, lead time is around 30~40days, and longer if need open new mould.

Q.3: What shipping tools you use for different orders shipment?

A. For small trial order,FEDEX, DHL, UPS, TNT etc can be provided.

B. For larger order,we can arrange shipment by sea or by air according to your requirement.

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can you provide examples of products or equipment that incorporate injection molded parts?

Yes, there are numerous products and equipment across various industries that incorporate injection molded parts. Injection molding is a widely used manufacturing process that enables the production of complex and precise components. Here are some examples of products and equipment that commonly incorporate injection molded parts:

1. Electronics and Consumer Devices:

– Mobile phones and smartphones: These devices typically have injection molded plastic casings, buttons, and connectors.

– Computers and laptops: Injection molded parts are used for computer cases, keyboard keys, connectors, and peripheral device housings.

– Appliances: Products such as televisions, refrigerators, washing machines, and vacuum cleaners often incorporate injection molded components for their casings, handles, buttons, and control panels.

– Audio equipment: Speakers, headphones, and audio players often use injection molded parts for their enclosures and buttons.

2. Automotive Industry:

– Cars and Trucks: Injection molded parts are extensively used in the automotive industry. Examples include dashboard panels, door handles, interior trim, steering wheel components, air vents, and various under-the-hood components.

– Motorcycle and Bicycle Parts: Many motorcycle and bicycle components are manufactured using injection molding, including fairings, handle grips, footrests, instrument panels, and engine covers.

– Automotive Lighting: Headlights, taillights, turn signals, and other automotive lighting components often incorporate injection molded lenses, housings, and mounts.

3. Medical and Healthcare:

– Medical Devices: Injection molding is widely used in the production of medical devices such as syringes, IV components, surgical instruments, respiratory masks, implantable devices, and diagnostic equipment.

– Laboratory Equipment: Many laboratory consumables, such as test tubes, petri dishes, pipette tips, and specimen containers, are manufactured using injection molding.

– Dental Equipment: Dental tools, orthodontic devices, and dental prosthetics often incorporate injection molded components.

4. Packaging Industry:

– Bottles and Containers: Plastic bottles and containers used for food, beverages, personal care products, and household chemicals are commonly produced using injection molding.

– Caps and Closures: Injection molded caps and closures are widely used in the packaging industry for bottles, jars, and tubes.

– Thin-Walled Packaging: Injection molding is used to produce thin-walled packaging products such as trays, cups, and lids for food and other consumer goods.

5. Toys and Games:

– Many toys and games incorporate injection molded parts. Examples include action figures, building blocks, puzzles, board game components, and remote-controlled vehicles.

6. Industrial Equipment and Tools:

– Industrial machinery: Injection molded parts are used in various industrial equipment and machinery, including components for manufacturing machinery, conveyor systems, and robotic systems.

– Power tools: Many components of power tools, such as housing, handles, switches, and guards, are manufactured using injection molding.

– Hand tools: Injection molded parts are incorporated into a wide range of hand tools, including screwdrivers, wrenches, pliers, and cutting tools.

These are just a few examples of products and equipment that incorporate injection molded parts. The versatility of injection molding allows for its application in a wide range of industries, enabling the production of high-quality components with complex geometries and precise specifications.

How do injection molded parts enhance the overall efficiency and functionality of products and equipment?

Injection molded parts play a crucial role in enhancing the overall efficiency and functionality of products and equipment. They offer numerous advantages that make them a preferred choice in various industries. Here’s a detailed explanation of how injection molded parts contribute to improved efficiency and functionality:

1. Design Flexibility:

Injection molding allows for intricate and complex part designs that can be customized to meet specific requirements. The flexibility in design enables the integration of multiple features, such as undercuts, threads, hinges, and snap fits, into a single molded part. This versatility enhances the functionality of the product or equipment by enabling the creation of parts that are precisely tailored to their intended purpose.

2. High Precision and Reproducibility:

Injection molding offers excellent dimensional accuracy and repeatability, ensuring consistent part quality throughout production. The use of precision molds and advanced molding techniques allows for the production of parts with tight tolerances and intricate geometries. This high precision and reproducibility enhance the efficiency of products and equipment by ensuring proper fit, alignment, and functionality of the molded parts.

3. Cost-Effective Mass Production:

Injection molding is a highly efficient and cost-effective method for mass production. Once the molds are created, the injection molding process can rapidly produce a large number of identical parts in a short cycle time. The ability to produce parts in high volumes streamlines the manufacturing process, reduces labor costs, and ensures consistent part quality. This cost-effectiveness contributes to overall efficiency and enables the production of affordable products and equipment.

4. Material Selection:

Injection molding offers a wide range of material options, including engineering thermoplastics, elastomers, and even certain metal alloys. The ability to choose from various materials with different properties allows manufacturers to select the most suitable material for each specific application. The right material selection enhances the functionality of the product or equipment by providing the desired mechanical, thermal, and chemical properties required for optimal performance.

5. Structural Integrity and Durability:

Injection molded parts are known for their excellent structural integrity and durability. The molding process ensures uniform material distribution, resulting in parts with consistent strength and reliability. The elimination of weak points, such as seams or joints, enhances the overall structural integrity of the product or equipment. Additionally, injection molded parts are resistant to impact, wear, and environmental factors, ensuring long-lasting functionality in demanding applications.

6. Integration of Features:

Injection molding enables the integration of multiple features into a single part. This eliminates the need for assembly or additional components, simplifying the manufacturing process and reducing production time and costs. The integration of features such as hinges, fasteners, or mounting points enhances the overall efficiency and functionality of the product or equipment by providing convenient and streamlined solutions.

7. Lightweight Design:

Injection molded parts can be manufactured with lightweight materials without compromising strength or durability. This is particularly advantageous in industries where weight reduction is critical, such as automotive, aerospace, and consumer electronics. The use of lightweight injection molded parts improves energy efficiency, reduces material costs, and enhances the overall performance and efficiency of the products and equipment.

8. Consistent Surface Finish:

Injection molding produces parts with a consistent and high-quality surface finish. The use of polished or textured molds ensures that the molded parts have smooth, aesthetic surfaces without the need for additional finishing operations. This consistent surface finish enhances the overall functionality and visual appeal of the product or equipment, contributing to a positive user experience.

9. Customization and Branding:

Injection molding allows for customization and branding options, such as incorporating logos, labels, or surface textures, directly into the molded parts. This customization enhances the functionality and marketability of products and equipment by providing a unique identity and reinforcing brand recognition.

Overall, injection molded parts offer numerous advantages that enhance the efficiency and functionality of products and equipment. Their design flexibility, precision, cost-effectiveness, material selection, structural integrity, lightweight design, and customization capabilities make them a preferred choice for a wide range of applications across industries.

What industries and applications commonly utilize injection molded parts?

Injection molded parts find widespread use across various industries and applications due to their versatility, cost-effectiveness, and ability to meet specific design requirements. Here’s a detailed explanation of the industries and applications that commonly utilize injection molded parts:

1. Automotive Industry:

The automotive industry extensively relies on injection molded parts for both interior and exterior components. These parts include dashboards, door panels, bumpers, grilles, interior trim, seating components, electrical connectors, and various engine and transmission components. Injection molding enables the production of lightweight, durable, and aesthetically pleasing parts that meet the stringent requirements of the automotive industry.

2. Consumer Electronics:

Injection molded parts are prevalent in the consumer electronics industry. They are used in the manufacturing of components such as housings, buttons, bezels, connectors, and structural parts for smartphones, tablets, laptops, gaming consoles, televisions, cameras, and other electronic devices. Injection molding allows for the production of parts with precise dimensions, excellent surface finish, and the ability to integrate features like snap fits, hinges, and internal structures.

3. Medical and Healthcare:

The medical and healthcare industry extensively utilizes injection molded parts for a wide range of devices and equipment. These include components for medical devices, diagnostic equipment, surgical instruments, drug delivery systems, laboratory equipment, and disposable medical products. Injection molding offers the advantage of producing sterile, biocompatible, and precise parts with tight tolerances, ensuring safety and reliability in medical applications.

4. Packaging and Containers:

Injection molded parts are commonly used in the packaging and container industry. These parts include caps, closures, bottles, jars, tubs, trays, and various packaging components. Injection molding allows for the production of lightweight, durable, and visually appealing packaging solutions. The process enables the integration of features such as tamper-evident seals, hinges, and snap closures, contributing to the functionality and convenience of packaging products.

5. Aerospace and Defense:

The aerospace and defense industries utilize injection molded parts for a variety of applications. These include components for aircraft interiors, cockpit controls, avionics, missile systems, satellite components, and military equipment. Injection molding offers the advantage of producing lightweight, high-strength parts with complex geometries, meeting the stringent requirements of the aerospace and defense sectors.

6. Industrial Equipment:

Injection molded parts are widely used in industrial equipment for various applications. These include components for machinery, tools, pumps, valves, electrical enclosures, connectors, and fluid handling systems. Injection molding provides the ability to manufacture parts with excellent dimensional accuracy, durability, and resistance to chemicals, oils, and other harsh industrial environments.

7. Furniture and Appliances:

The furniture and appliance industries utilize injection molded parts for various components. These include handles, knobs, buttons, hinges, decorative elements, and structural parts for furniture, kitchen appliances, household appliances, and white goods. Injection molding enables the production of parts with aesthetic appeal, functional design, and the ability to withstand regular use and environmental conditions.

8. Toys and Recreational Products:

Injection molded parts are commonly found in the toy and recreational product industry. They are used in the manufacturing of plastic toys, games, puzzles, sporting goods, outdoor equipment, and playground components. Injection molding allows for the production of colorful, durable, and safe parts that meet the specific requirements of these products.

9. Electrical and Electronics:

Injection molded parts are widely used in the electrical and electronics industry. They are employed in the production of electrical connectors, switches, sockets, wiring harness components, enclosures, and other electrical and electronic devices. Injection molding offers the advantage of producing parts with excellent dimensional accuracy, electrical insulation properties, and the ability to integrate complex features.

10. Plumbing and Pipe Fittings:

The plumbing and pipe fittings industry relies on injection molded parts for various components. These include fittings, valves, connectors, couplings, and other plumbing system components. Injection molding provides the ability to manufacture parts with precise dimensions, chemical resistance, and robustness, ensuring leak-free connections and long-term performance.

In summary, injection molded parts are utilized in a wide range of industries and applications. The automotive, consumer electronics, medical and healthcare, packaging, aerospace and defense, industrial equipment, furniture and appliances, toys and recreational products, electrical and electronics, and plumbing industries commonly rely on injection molding for the production of high-quality, cost-effective, and functionally optimized parts.

editor by Dream 2024-11-18

China manufacturer ISO Certificate Injection Molding Black ABS/PP/PA6 Plastic Molded Parts

Product Description

Product Description

| Product Specifications | |

| Service | Mold design & production, bulk production, material modification, surface treatment, assembly, custom packaging. |

| Technology | Injection molding, CNC machining, extrusion, compression molding, over molding & insert molding. |

| Material | Rubber: NR, NBR, Neoprene, EPDM, Silicone, FKM, BR/SBR, PU, TPE, TPV, TPU,etc. Plastic: PA, ABS, POM, PP, PE, LDPE, HDPE, UHMWPE, PTFE, PVC, PC, PS, etc. |

| Additives | UV absorbers, flame retardants, plasticizers, colorants, carbon fibers, glass fibers. |

| Color | Any color according to pantone code. |

| Size | As your requirement. |

| Biggest Part Size | 2000*1500*1000mm |

| Surface Treatment | Polishing, glossy, texture, matte. |

| Drawing Format | 2D Drawing: PDF/JPG/PNG 3D Drawing: STEP/STP/IGS/DXF/DWG |

OEM & ODM Manufacturer

One-stop service from design to assembly

We can support

- Mould design and production

- Custom plastic parts

- Custom rubber parts

- Custom urethane parts

- Finished parts assembly service

- Custom packaging service

Certifications: ISO9001:2015 & SGS

Main Products

Plastic Parts

Available Materials: ABS, Nylon, POM, PP, PE, LDPE, HDPE, UHMW, PTFE, PU, PC, PS, PVC, etc.

Rubber Parts

Available Materials: NR, NBR, SBR, CR, Silicone, FVMQ, FKM, EPDM, IR, IIR, TPV, TPE, TPU, etc.

Polyurethane Parts

Polyurethane (PU) is a technical thermoplastic. It has excellent mechanical properties, high elasticity, and mold ability.

Company Profile

ZheJiang Erye Rubber and Plastic Co., Ltd. is a leading provider of custom rubber and CHINAMFG established in 2008. With over a decade of industry experience, we take pride in our unwavering commitment to CHINAMFG and customer satisfaction. Serving customers across more than 50 countries worldwide, we have earned a reputation as a reliable partner in delivering high-quality products tailored to meet diverse industrial needs. Our extensive clientele includes automotive, energy, mining, agricultural, robotic, and various other industries.

Our Advantages

Our Customers

Certifications

The quality of our parts conforms to ISO9001 standard. We take quality control from IQC to OQC seriously, throughout every step of production, and strive to meet customer expectations in all aspects of the product manufacturing process.

Packaging & Shipping

Our package: pack in bulk, poly bag, gift box, or special custom package request according to customers. All cartons have passed the box drop test to ensure that the products received by customers are in good condition.

FAQ

Q1. How soon can I get a precise quotation for custom plastic injection molding parts?

Please send us your inquiry by email or online message. Once we confirm the design, material, color, qty, we can provide quotation within 24 hours.

Q2: Can you make custom parts based on my sample?

Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.

Q3. What contract manufacturing services do you provide?

Our expertise includes engineering, product design, injection molding, custom molding, sub-and-finished assembly and the on-time delivery of components and finished products for major industries.

Q4. What are your manufacturing hours of operation?

Our facility operates 24 hours a day, 7 days a week.

Q5. Do you manufacture the molds and parts at your facility?

Yes, all the mold and parts are manufactured and assembled in our 30,000 sqm facility.

Q6. What certifications does Erye have?

Erye is an ISO9001-certified company. We can send you our current ISO certification CHINAMFG request.

Q7. What types of secondary or assembly options do you perform?

We provide manual assembly, semi-automated assembly, machining and special packaging.Fully automated assembly services can also be done if the volume is sufficient.

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How does the injection molding process contribute to the production of high-precision parts?

The injection molding process is widely recognized for its ability to produce high-precision parts with consistent quality. Several factors contribute to the precision achieved through injection molding:

1. Tooling and Mold Design:

The design and construction of the injection mold play a crucial role in achieving high precision. The mold is typically made with precision machining techniques, ensuring accurate dimensions and tight tolerances. The mold design considers factors such as part shrinkage, cooling channels, gate location, and ejection mechanisms, all of which contribute to dimensional accuracy and part stability during the molding process.

2. Material Control:

Injection molding allows for precise control over the material used in the process. The molten plastic material is carefully measured and controlled, ensuring consistent material properties and reducing variations in the molded parts. This control over material parameters, such as melt temperature, viscosity, and fill rate, contributes to the production of high-precision parts with consistent dimensions and mechanical properties.

3. Injection Process Control:

The injection molding process involves injecting molten plastic into the mold cavity under high pressure. Advanced injection molding machines are equipped with precise control systems that regulate the injection speed, pressure, and time. These control systems ensure accurate and repeatable filling of the mold, minimizing variations in part dimensions and surface finish. The ability to finely tune and control these parameters contributes to the production of high-precision parts.

4. Cooling and Solidification:

Proper cooling and solidification of the injected plastic material are critical for achieving high precision. The cooling process is carefully controlled to ensure uniform cooling throughout the part and to minimize warping or distortion. Efficient cooling systems in the mold, such as cooling channels or conformal cooling, help maintain consistent temperatures and solidification rates, resulting in precise part dimensions and reduced internal stresses.

5. Automation and Robotics:

The use of automation and robotics in injection molding enhances precision and repeatability. Automated systems ensure consistent and precise handling of molds, inserts, and finished parts, reducing human errors and variations. Robots can perform tasks such as part removal, inspection, and assembly with high accuracy, contributing to the overall precision of the production process.

6. Process Monitoring and Quality Control:

Injection molding processes often incorporate advanced monitoring and quality control systems. These systems continuously monitor and analyze key process parameters, such as temperature, pressure, and cycle time, to detect any variations or deviations. Real-time feedback from these systems allows for adjustments and corrective actions, ensuring that the production remains within the desired tolerances and quality standards.

7. Post-Processing and Finishing:

After the injection molding process, post-processing and finishing techniques, such as trimming, deburring, and surface treatments, can further enhance the precision and aesthetics of the parts. These processes help remove any imperfections or excess material, ensuring that the final parts meet the specified dimensional and cosmetic requirements.

Collectively, the combination of precise tooling and mold design, material control, injection process control, cooling and solidification techniques, automation and robotics, process monitoring, and post-processing contribute to the production of high-precision parts through the injection molding process. The ability to consistently achieve tight tolerances, accurate dimensions, and excellent surface finish makes injection molding a preferred choice for applications that demand high precision.

How do innovations and advancements in injection molding technology influence part design and production?

Innovations and advancements in injection molding technology have a significant influence on part design and production. These advancements introduce new capabilities, enhance process efficiency, improve part quality, and expand the range of applications for injection molded parts. Here’s a detailed explanation of how innovations and advancements in injection molding technology influence part design and production:

Design Freedom:

Advancements in injection molding technology have expanded the design freedom for part designers. With the introduction of advanced software tools, such as computer-aided design (CAD) and simulation software, designers can create complex geometries, intricate features, and highly optimized designs. The use of 3D modeling and simulation allows for the identification and resolution of potential design issues before manufacturing. This design freedom enables the production of innovative and highly functional parts that were previously challenging or impossible to manufacture using conventional techniques.

Improved Precision and Accuracy:

Innovations in injection molding technology have led to improved precision and accuracy in part production. High-precision molds, advanced control systems, and closed-loop feedback mechanisms ensure precise control over the molding process variables, such as temperature, pressure, and cooling. This level of control results in parts with tight tolerances, consistent dimensions, and improved surface finishes. Enhanced precision and accuracy enable the production of parts that meet strict quality requirements, fit seamlessly with other components, and perform reliably in their intended applications.

Material Advancements:

The development of new materials and material combinations specifically formulated for injection molding has expanded the range of properties available to part designers. Innovations in materials include high-performance engineering thermoplastics, bio-based polymers, reinforced composites, and specialty materials with unique properties. These advancements allow for the production of parts with enhanced mechanical strength, improved chemical resistance, superior heat resistance, and customized performance characteristics. Material advancements in injection molding technology enable the creation of parts that can withstand demanding operating conditions and meet the specific requirements of various industries.

Process Efficiency:

Innovations in injection molding technology have introduced process optimizations that improve efficiency and productivity. Advanced automation, robotics, and real-time monitoring systems enable faster cycle times, reduced scrap rates, and increased production throughput. Additionally, innovations like multi-cavity molds, hot-runner systems, and micro-injection molding techniques improve material utilization and reduce production costs. Increased process efficiency allows for the economical production of high-quality parts in larger quantities, meeting the demands of industries that require high-volume production.

Overmolding and Multi-Material Molding:

Advancements in injection molding technology have enabled the integration of multiple materials or components into a single part through overmolding or multi-material molding processes. Overmolding allows for the encapsulation of inserts, such as metal components or electronics, with a thermoplastic material in a single molding cycle. This enables the creation of parts with improved functionality, enhanced aesthetics, and simplified assembly. Multi-material molding techniques, such as co-injection molding or sequential injection molding, enable the production of parts with multiple colors, varying material properties, or complex material combinations. These capabilities expand the design possibilities and allow for the creation of innovative parts with unique features and performance characteristics.

Additive Manufacturing Integration:

The integration of additive manufacturing, commonly known as 3D printing, with injection molding technology has opened up new possibilities for part design and production. Additive manufacturing can be used to create complex mold geometries, conformal cooling channels, or custom inserts, which enhance part quality, reduce cycle times, and improve part performance. By combining additive manufacturing and injection molding, designers can explore new design concepts, produce rapid prototypes, and efficiently manufacture customized or low-volume production runs.

Sustainability and Eco-Friendly Solutions:

Advancements in injection molding technology have also focused on sustainability and eco-friendly solutions. This includes the development of biodegradable and compostable materials, recycling technologies for post-consumer and post-industrial waste, and energy-efficient molding processes. These advancements enable the production of environmentally friendly parts that contribute to reducing the carbon footprint and meeting sustainability goals.

Overall, innovations and advancements in injection molding technology have revolutionized part design and production. They have expanded design possibilities, improved precision and accuracy, introduced new materials, enhanced process efficiency, enabled overmolding and multi-material molding, integrated additive manufacturing, and promoted sustainability. These advancements empower part designers and manufacturers to create highly functional, complex, and customized parts that meet the demands of various industries and contribute to overall process efficiency and sustainability.

What are injection molded parts, and how are they manufactured?

Injection molded parts are components or products that are produced through the injection molding manufacturing process. Injection molding is a widely used manufacturing technique for creating plastic parts with high precision, complexity, and efficiency. Here’s a detailed explanation of injection molded parts and the process of manufacturing them:

Injection Molding Process:

The injection molding process involves the following steps:

1. Mold Design:

The first step in manufacturing injection molded parts is designing the mold. The mold is a custom-made tool that defines the shape and features of the final part. It is typically made from steel or aluminum and consists of two halves: the cavity and the core. The mold design takes into account factors such as part geometry, material selection, cooling requirements, and ejection mechanism.

2. Material Selection:

The next step is selecting the appropriate material for the injection molding process. Thermoplastic polymers are commonly used due to their ability to melt and solidify repeatedly without significant degradation. The material choice depends on the desired properties of the final part, such as strength, flexibility, transparency, or chemical resistance.

3. Melting and Injection:

In the injection molding machine, the selected thermoplastic material is melted and brought to a molten state. The molten material, called the melt, is then injected into the mold under high pressure. The injection is performed through a nozzle and a runner system that delivers the molten material to the mold cavity.

4. Cooling:

After the molten material is injected into the mold, it begins to cool and solidify. Cooling is a critical phase of the injection molding process as it determines the final part’s dimensional accuracy, strength, and other properties. The mold is designed with cooling channels or inserts to facilitate the efficient and uniform cooling of the part. Cooling time can vary depending on factors such as part thickness, material properties, and mold design.

5. Mold Opening and Ejection:

Once the injected material has sufficiently cooled and solidified, the mold opens, separating the two halves. Ejector pins or other mechanisms are used to push or release the part from the mold cavity. The ejection system must be carefully designed to avoid damaging the part during the ejection process.

6. Finishing:

After ejection, the injection molded part may undergo additional finishing processes, such as trimming excess material, removing sprues or runners, and applying surface treatments or textures. These processes help achieve the desired final appearance and functionality of the part.

Advantages of Injection Molded Parts:

Injection molded parts offer several advantages:

1. High Precision and Complexity:

Injection molding allows for the creation of parts with high precision and intricate details. The molds can produce complex shapes, fine features, and precise dimensions, enabling the manufacturing of parts with tight tolerances.

2. Cost-Effective Mass Production:

Injection molding is a highly efficient process suitable for large-scale production. Once the mold is created, the manufacturing process can be automated, resulting in fast and cost-effective production of identical parts. The high production volumes help reduce per-unit costs.

3. Material Versatility:

Injection molding supports a wide range of thermoplastic materials, allowing for versatility in material selection based on the desired characteristics of the final part. Different materials can be used to achieve specific properties such as strength, flexibility, heat resistance, or chemical resistance.

4. Strength and Durability:

Injection molded parts can exhibit excellent strength and durability. The molding process ensures that the material is uniformly distributed, resulting in consistent mechanical properties throughout the part. This makes injection molded parts suitable for various applications that require structural integrity and longevity.

5. Minimal Post-Processing:

Injection molded parts often require minimal post-processing. The high precision and quality achieved during the molding process reduce the need for extensive additional machining or finishing operations, saving time and costs.

6. Design Flexibility:

With injection molding, designers have significant flexibility in part design. The process can accommodate complex geometries, undercuts, thin walls, and other design features that may be challenging or costly with other manufacturing methods. This flexibility allows for innovation and optimization of part functionality.

In summary, injection molded parts are components or products manufactured through the injection molding process. This process involves designing amold, selecting the appropriate material, melting and injecting the material into the mold, cooling and solidifying the part, opening the mold and ejecting the part, and applying finishing processes as necessary. Injection molded parts offer advantages such as high precision, complexity, cost-effective mass production, material versatility, strength and durability, minimal post-processing, and design flexibility. These factors contribute to the widespread use of injection molding in various industries for producing high-quality plastic parts.

<img src="https://img.hzpt.com/img/Injectionmoldedparts/Injectionmoldedparts-L1.webp" alt="China manufacturer ISO Certificate Injection Molding Black ABS/PP/PA6 Plastic Molded Parts “><img src="https://img.hzpt.com/img/Injectionmoldedparts/Injectionmoldedparts-L2.webp" alt="China manufacturer ISO Certificate Injection Molding Black ABS/PP/PA6 Plastic Molded Parts “>

editor by Dream 2024-10-16

China OEM High Precision Custom Injection Molded Parts Injection Molding Milling Turning Stamping PMMA Poe ABS PTFE Parts

Product Description

| High Precision CNC OEM Machining Supplier | |

| Service | CNC Turning, CNC Milling, Laser Cutting, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Plastic Molding, |

| Materials | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc 3). Steel: 45#, Q235, Q345B 4). Titanium: TA1,TA2/GR2,TA4/GR5 5). Brass: C36000 (HPb62) 6). Copper, bronze, POM, Acrylic, PC, etc. |

| Surface Treatment | Sandblasting, Anodize, Zinc/Nickl Plating, Polish |

| Processing Technology | CNC machining parts, turning/milling process |

| MOQ | 1pcs |

| Lead Time | Sample: 3-5 days. Mass Production: within 10-25 days after receiving the deposit. |

| Package | 1)pp bags + carton or wooden case 2) according to customers’ requirements 3)negotiable |

| Payment Terms | Trade Assurance, T/T/ West Union |

Certifications

FAQ

1. Are you a manufacturer or a trading company?

We are the set design, development, production, sale, and service of industry and trade-oriented enterprises,dedicate to precision CNC machining services customized for non-standard products.

2. How can I get a quote?

Please offer 2D or 3D drawings (PDF/STEP/IGS/DWG…) with material, dimension, tolerance, surface treatment, quantity, and other technical requirement, etc. We will offer a quotation in 24 hours.

3. Can I get a quote without drawings?

Sure, we appreciate receiving your samples, pictures, or drafts with detailed dimensions for an accurate quotation.

4. Will my drawings be divulged if you benefit?

No, we pay much attention to protecting our customers’ privacy, and signing NDA are also accepted if needed.

5. Can you provide samples for free?

Our sample is free, Freight charge only.

6. How about the lead time?

Generally, 5-7 days for samples, and 3-4 weeks for mass production.

7. How do you control the quality?

(1) Material inspection–Check the material surface and rough dimensions.

(2) Production first inspection–To ensure the critical dimension in mass production.

(3) Sampling inspection–Check the quality before sending it to the warehouse.

(4) Pre-shipment inspection–100% inspected by QC before shipment.

8. How do I know the progress of my order?

We will offer a detailed product schedule and send weekly reports with digital pictures and videos which show the machining progress.

9. What will you do if we receive poor-quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How does the injection molding process contribute to the production of high-precision parts?

The injection molding process is widely recognized for its ability to produce high-precision parts with consistent quality. Several factors contribute to the precision achieved through injection molding:

1. Tooling and Mold Design:

The design and construction of the injection mold play a crucial role in achieving high precision. The mold is typically made with precision machining techniques, ensuring accurate dimensions and tight tolerances. The mold design considers factors such as part shrinkage, cooling channels, gate location, and ejection mechanisms, all of which contribute to dimensional accuracy and part stability during the molding process.

2. Material Control:

Injection molding allows for precise control over the material used in the process. The molten plastic material is carefully measured and controlled, ensuring consistent material properties and reducing variations in the molded parts. This control over material parameters, such as melt temperature, viscosity, and fill rate, contributes to the production of high-precision parts with consistent dimensions and mechanical properties.

3. Injection Process Control:

The injection molding process involves injecting molten plastic into the mold cavity under high pressure. Advanced injection molding machines are equipped with precise control systems that regulate the injection speed, pressure, and time. These control systems ensure accurate and repeatable filling of the mold, minimizing variations in part dimensions and surface finish. The ability to finely tune and control these parameters contributes to the production of high-precision parts.

4. Cooling and Solidification:

Proper cooling and solidification of the injected plastic material are critical for achieving high precision. The cooling process is carefully controlled to ensure uniform cooling throughout the part and to minimize warping or distortion. Efficient cooling systems in the mold, such as cooling channels or conformal cooling, help maintain consistent temperatures and solidification rates, resulting in precise part dimensions and reduced internal stresses.

5. Automation and Robotics:

The use of automation and robotics in injection molding enhances precision and repeatability. Automated systems ensure consistent and precise handling of molds, inserts, and finished parts, reducing human errors and variations. Robots can perform tasks such as part removal, inspection, and assembly with high accuracy, contributing to the overall precision of the production process.

6. Process Monitoring and Quality Control:

Injection molding processes often incorporate advanced monitoring and quality control systems. These systems continuously monitor and analyze key process parameters, such as temperature, pressure, and cycle time, to detect any variations or deviations. Real-time feedback from these systems allows for adjustments and corrective actions, ensuring that the production remains within the desired tolerances and quality standards.

7. Post-Processing and Finishing:

After the injection molding process, post-processing and finishing techniques, such as trimming, deburring, and surface treatments, can further enhance the precision and aesthetics of the parts. These processes help remove any imperfections or excess material, ensuring that the final parts meet the specified dimensional and cosmetic requirements.

Collectively, the combination of precise tooling and mold design, material control, injection process control, cooling and solidification techniques, automation and robotics, process monitoring, and post-processing contribute to the production of high-precision parts through the injection molding process. The ability to consistently achieve tight tolerances, accurate dimensions, and excellent surface finish makes injection molding a preferred choice for applications that demand high precision.

Are there specific considerations for choosing injection molded parts in applications with varying environmental conditions or industry standards?

Yes, there are specific considerations to keep in mind when choosing injection molded parts for applications with varying environmental conditions or industry standards. These factors play a crucial role in ensuring that the selected parts can withstand the specific operating conditions and meet the required standards. Here’s a detailed explanation of the considerations for choosing injection molded parts in such applications:

1. Material Selection:

The choice of material for injection molded parts is crucial when considering varying environmental conditions or industry standards. Different materials offer varying levels of resistance to factors such as temperature extremes, UV exposure, chemicals, moisture, or mechanical stress. Understanding the specific environmental conditions and industry requirements is essential in selecting a material that can withstand these conditions while meeting the necessary standards for performance, durability, and safety.

2. Temperature Resistance:

In applications with extreme temperature variations, it is important to choose injection molded parts that can withstand the specific temperature range. Some materials, such as engineering thermoplastics, exhibit excellent high-temperature resistance, while others may be more suitable for low-temperature environments. Consideration should also be given to the potential for thermal expansion or contraction, as it can affect the dimensional stability and overall performance of the parts.

3. Chemical Resistance:

In industries where exposure to chemicals is common, it is critical to select injection molded parts that can resist chemical attack and degradation. Different materials have varying levels of chemical resistance, and it is important to choose a material that is compatible with the specific chemicals present in the application environment. Consideration should also be given to factors such as prolonged exposure, concentration, and frequency of contact with chemicals.

4. UV Stability:

For applications exposed to outdoor environments or intense UV radiation, selecting injection molded parts with UV stability is essential. UV radiation can cause material degradation, discoloration, or loss of mechanical properties over time. Materials with UV stabilizers or additives can provide enhanced resistance to UV radiation, ensuring the longevity and performance of the parts in outdoor or UV-exposed applications.

5. Mechanical Strength and Impact Resistance:

In applications where mechanical stress or impact resistance is critical, choosing injection molded parts with the appropriate mechanical properties is important. Materials with high tensile strength, impact resistance, or toughness can ensure that the parts can withstand the required loads, vibrations, or impacts without failure. Consideration should also be given to factors such as fatigue resistance, abrasion resistance, or flexibility, depending on the specific application requirements.

6. Compliance with Industry Standards:

When selecting injection molded parts for applications governed by industry standards or regulations, it is essential to ensure that the chosen parts comply with the required standards. This includes standards for dimensions, tolerances, safety, flammability, electrical properties, or specific performance criteria. Choosing parts that are certified or tested to meet the relevant industry standards helps ensure compliance and reliability in the intended application.

7. Environmental Considerations:

In today’s environmentally conscious landscape, considering the sustainability and environmental impact of injection molded parts is increasingly important. Choosing materials that are recyclable or biodegradable can align with sustainability goals. Additionally, evaluating factors such as energy consumption during manufacturing, waste reduction, or the use of environmentally friendly manufacturing processes can contribute to environmentally responsible choices.

8. Customization and Design Flexibility:

Lastly, the design flexibility and customization options offered by injection molded parts can be advantageous in meeting specific environmental or industry requirements. Injection molding allows for intricate designs, complex geometries, and the incorporation of features such as gaskets, seals, or mounting points. Customization options for color, texture, or surface finish can also be considered to meet specific branding or aesthetic requirements.

Considering these specific considerations when choosing injection molded parts for applications with varying environmental conditions or industry standards ensures that the selected parts are well-suited for their intended use, providing optimal performance, durability, and compliance with the required standards.

How do injection molded parts compare to other manufacturing methods in terms of cost and efficiency?

Injection molded parts have distinct advantages over other manufacturing methods when it comes to cost and efficiency. The injection molding process offers high efficiency and cost-effectiveness, especially for large-scale production. Here’s a detailed explanation of how injection molded parts compare to other manufacturing methods:

Cost Comparison:

Injection molding can be cost-effective compared to other manufacturing methods for several reasons:

1. Tooling Costs:

Injection molding requires an initial investment in creating molds, which can be costly. However, once the molds are made, they can be used repeatedly for producing a large number of parts, resulting in a lower per-unit cost. The amortized tooling costs make injection molding more cost-effective for high-volume production runs.

2. Material Efficiency:

Injection molding is highly efficient in terms of material usage. The process allows for precise control over the amount of material injected into the mold, minimizing waste. Additionally, excess material from the molding process can be recycled and reused, further reducing material costs compared to methods that generate more significant amounts of waste.

3. Labor Costs:

Injection molding is a highly automated process, requiring minimal labor compared to other manufacturing methods. Once the molds are set up and the process parameters are established, the injection molding machine can run continuously, producing parts with minimal human intervention. This automation reduces labor costs and increases overall efficiency.

Efficiency Comparison:

Injection molded parts offer several advantages in terms of efficiency:

1. Rapid Production Cycle:

Injection molding is a fast manufacturing process, capable of producing parts in a relatively short cycle time. The cycle time depends on factors such as part complexity, material properties, and cooling time. However, compared to other methods such as machining or casting, injection molding can produce multiple parts simultaneously in each cycle, resulting in higher production rates and improved efficiency.

2. High Precision and Consistency:

Injection molding enables the production of parts with high precision and consistency. The molds used in injection molding are designed to provide accurate and repeatable dimensional control. This precision ensures that each part meets the required specifications, reducing the need for additional machining or post-processing operations. The ability to consistently produce precise parts enhances efficiency and reduces time and costs associated with rework or rejected parts.

3. Scalability:

Injection molding is highly scalable, making it suitable for both low-volume and high-volume production. Once the molds are created, the injection molding process can be easily replicated, allowing for efficient production of identical parts. The ability to scale production quickly and efficiently makes injection molding a preferred method for meeting changing market demands.

4. Design Complexity:

Injection molding supports the production of parts with complex geometries and intricate details. The molds can be designed to accommodate undercuts, thin walls, and complex shapes that may be challenging or costly with other manufacturing methods. This flexibility in design allows for the integration of multiple components into a single part, reducing assembly requirements and potential points of failure. The ability to produce complex designs efficiently enhances overall efficiency and functionality.

5. Material Versatility:

Injection molding supports a wide range of thermoplastic materials, providing versatility in material selection based on the desired properties of the final part. Different materials can be chosen to achieve specific characteristics such as strength, flexibility, heat resistance, chemical resistance, or transparency. This material versatility allows for efficient customization and optimization of part performance.

In summary, injection molded parts are cost-effective and efficient compared to many other manufacturing methods. The initial tooling costs are offset by the ability to produce a large number of parts at a lower per-unit cost. The material efficiency, labor automation, rapid production cycle, high precision, scalability, design complexity, and material versatility contribute to the overall cost-effectiveness and efficiency of injection molding. These advantages make injection molding a preferred choice for various industries seeking to produce high-quality parts efficiently and economically.

<img src="https://img.hzpt.com/img/Injectionmoldedparts/Injectionmoldedparts-L1.webp" alt="China OEM High Precision Custom Injection Molded Parts Injection Molding Milling Turning Stamping PMMA Poe ABS PTFE Parts “><img src="https://img.hzpt.com/img/Injectionmoldedparts/Injectionmoldedparts-L2.webp" alt="China OEM High Precision Custom Injection Molded Parts Injection Molding Milling Turning Stamping PMMA Poe ABS PTFE Parts “>

editor by Dream 2024-10-15

China wholesaler Customized Molded CHINAMFG for Fixed Installation and Injection Moulding

Product Description

Item: Custom PP Molded Plastic Injection Machining Parts Embrace precision and versatility with our Custom PP Molded Plastic Injection Machining Parts. Designed with an emphasis on durability and adaptability, these parts are engineered to meet the unique specifications of your project, ensuring a seamless integration into your production process.

Workshop View Take a glimpse into the heart of our operations. Our workshop is a testament to our commitment to quality and precision, equipped with advanced machinery and staffed by skilled professionals dedicated to crafting top-tier plastic parts.

| Mold Material | S45C, S50C, P20, 718H, 738H, NAK80, S136, S136H |

| Mold Life Time | Life time warrange,you pay mold cost once and we will be responsible for all quality production |

| Product Material | PC, ABS,PP,PC+ABS,PA, HIPS, PVC, PE, PS, POM, Acrylic,TPE,PET,GF filled PA etc |

| Surface | Smooth, Glossy, Textured, Matte/Sandblasting |

| Color | Any Pantone or RAL color code is workable |

| Drawing Format | STEP/IGS/X_T,DWG,PDF |

| Secondary Service | Painting,Printing,Chrome Plating,Assembly etc. |

| Delivery Time | 2 to 8 weeks depending on order size |

Careful Working Discover the meticulous attention to detail that defines our work ethic. At HangZhou SHINER PLASTICS MANUFACTORY CO., LTD., every step of our production process is handled with the utmost care to ensure the highest quality standards are met.

Example of What We Do Delve into our diverse portfolio that showcases the breadth of our capabilities in creating custom molded CHINAMFG tailored to your needs, from concept to completion.

Company Introduction Welcome to HangZhou SHINER PLASTICS MANUFACTORY CO., LTD., a leader in the realm of custom molded plastic parts. Our expertise spans across manufacturing, design, and innovative solutions, all tailored to meet the specific demands of our clients.

Q: Are you a factory or trading company?

A: We are a factory specializing in custom plastic injection molding parts, rubber components, and post-production services such as painting, printing, and assembly. Our comprehensive approach ensures a seamless production experience from start to finish.

Q: What info do you need if I want to get a quote for a custom plastic part?

A: Preferably, a 3D drawing in IGS/STEP/X-T format. However, other formats providing equivalent information are also acceptable, such as CAD drawings with weight specifications or physical samples for evaluation.

Additionally, please specify any special requirements or desired quantities, like painting, printing, or assembly, to receive the most accurate quote.

Q: What materials can you handle?

A: We expertly work with a wide array of plastics including PC, PP, ABS, Nylon, PA6, PA66, TPE, PVC, PBT, and Nylon with Glass Fiber, as well as subber parts in NBR and Silicone. This diversity allows us to cater to a variety of project specifications.

Q: I have a custom plastic part to make. I have the design but am not familiar with injection. Can you advise?

A: Absolutely. Our experienced engineering team is well-versed in both part design and injection feasibility. CHINAMFG receiving your design, we will thoroughly evaluate its suitability for injection molding, identifying any potential issues such as unnecessary plastic that could increase costs or cause surface sinks. We provide feedback to optimize your design before production begins.

Q: What colors can you do with my plastic part?

A: We can produce any color available within the Pantone and RAL color systems, allowing for a customized aesthetic that aligns with your brand vision.

Q: What’s your lead time for mold and for production?

A: Typically, we deliver samples within 30-35 days from mold order confirmation. Production lead times range from 2 to 8 weeks, contingent on order size, to ensure your schedule is perfectly met.

Q: What’s the mold life guarantee?

A: We offer a lifetime guarantee on molds. For molds that may age after approximately 500,000 shots, we commit to creating a new mold at no extra cost if your order reaches this level, ensuring continuous, hassle-free production.

Q: Is the mold our property after we pay it in full?

A: Yes, the mold becomes your property CHINAMFG full payment. We maintain it securely in-house exclusively for your production needs, ensuring no unauthorized usage or modifications occur without your consent.

Q: What’s your delivery terms?

A: We offer EXW pricing for air shipments and FOB HangZhou for sea shipments, given our strategic location near the HangZhou port. We are also flexible to coordinate shipments to other destinations at negotiable rates, ensuring your logistical needs are efficiently met.

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can injection molded parts be customized or modified to meet unique industrial needs?

Yes, injection molded parts can be customized or modified to meet unique industrial needs. The injection molding process offers flexibility and versatility, allowing for the production of highly customized parts with specific design requirements. Here’s a detailed explanation of how injection molded parts can be customized or modified:

Design Customization:

The design of an injection molded part can be tailored to meet unique industrial needs. Design customization involves modifying the part’s geometry, features, and dimensions to achieve specific functional requirements. This can include adding or removing features, changing wall thicknesses, incorporating undercuts or threads, and optimizing the part for assembly or integration with other components. Computer-aided design (CAD) tools and engineering expertise are used to create custom designs that address the specific industrial needs.

Material Selection:

The choice of material for injection molded parts can be customized based on the unique industrial requirements. Different materials possess distinct properties, such as strength, stiffness, chemical resistance, and thermal stability. By selecting the most suitable material, the performance and functionality of the part can be optimized for the specific application. Material customization ensures that the injection molded part can withstand the environmental conditions, operational stresses, and chemical exposures associated with the industrial application.

Surface Finishes:

The surface finish of injection molded parts can be customized to meet specific industrial needs. Surface finishes can range from smooth and polished to textured or patterned, depending on the desired aesthetic appeal, functional requirements, or ease of grip. Custom surface finishes can enhance the part’s appearance, provide additional protection against wear or corrosion, or enable specific interactions with other components or equipment.

Color and Appearance:

Injection molded parts can be customized in terms of color and appearance. Colorants can be added to the material during the molding process to achieve specific shades or color combinations. This customization option is particularly useful when branding, product differentiation, or visual identification is required. Additionally, surface textures, patterns, or special effects can be incorporated into the mold design to create unique appearances or visual effects.

Secondary Operations:

Injection molded parts can undergo secondary operations to further customize or modify them according to unique industrial needs. These secondary operations can include post-molding processes such as machining, drilling, tapping, welding, heat treating, or applying coatings. These operations enable the addition of specific features or functionalities that may not be achievable through the injection molding process alone. Secondary operations provide flexibility for customization and allow for the integration of injection molded parts into complex assemblies or systems.

Tooling Modifications:

If modifications or adjustments are required for an existing injection molded part, the tooling can be modified or reconfigured to accommodate the changes. Tooling modifications can involve altering the mold design, cavity inserts, gating systems, or cooling channels. This allows for the production of modified parts without the need for creating an entirely new mold. Tooling modifications provide cost-effective options for customizing or adapting injection molded parts to meet evolving industrial needs.

Prototyping and Iterative Development:

Injection molding enables the rapid prototyping and iterative development of parts. By using 3D printing or soft tooling, prototype molds can be created to produce small quantities of custom parts for testing, validation, and refinement. This iterative development process allows for modifications and improvements to be made based on real-world feedback, ensuring that the final injection molded parts meet the unique industrial needs effectively.

Overall, injection molded parts can be customized or modified to meet unique industrial needs through design customization, material selection, surface finishes, color and appearance options, secondary operations, tooling modifications, and iterative development. The flexibility and versatility of the injection molding process make it a valuable manufacturing method for creating highly customized parts that address specific industrial requirements.

What is the role of design software and CAD/CAM technology in optimizing injection molded parts?

Design software and CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) technology play a crucial role in optimizing injection molded parts. They provide powerful tools and capabilities that enable designers and engineers to improve the efficiency, functionality, and quality of the parts. Here’s a detailed explanation of the role of design software and CAD/CAM technology in optimizing injection molded parts:

1. Design Visualization and Validation:

Design software and CAD tools allow designers to create 3D models of injection molded parts, providing a visual representation of the product before manufacturing. These tools enable designers to validate and optimize the part design by simulating its behavior under various conditions, such as stress analysis, fluid flow, or thermal performance. This visualization and validation process help identify potential issues or areas for improvement, leading to optimized part designs.

2. Design Optimization:

Design software and CAD/CAM technology provide powerful optimization tools that enable designers to refine and improve the performance of injection molded parts. These tools include features such as parametric modeling, shape optimization, and topology optimization. Parametric modeling allows for quick iteration and exploration of design variations, while shape and topology optimization algorithms help identify the most efficient and lightweight designs that meet the required functional and structural criteria.

3. Mold Design:

Design software and CAD/CAM technology are instrumental in the design of injection molds used to produce the molded parts. Mold design involves creating the 3D geometry of the mold components, such as the core, cavity, runner system, and cooling channels. CAD/CAM tools provide specialized features for mold design, including mold flow analysis, which simulates the injection molding process to optimize mold filling, cooling, and part ejection. This ensures the production of high-quality parts with minimal defects and cycle time.

4. Design for Manufacturability:

Design software and CAD/CAM technology facilitate the implementation of Design for Manufacturability (DFM) principles in the design process. DFM focuses on designing parts that are optimized for efficient and cost-effective manufacturing. CAD tools provide features that help identify and address potential manufacturing issues early in the design stage, such as draft angles, wall thickness variations, or parting line considerations. By considering manufacturing constraints during the design phase, injection molded parts can be optimized for improved manufacturability, reduced production costs, and shorter lead times.

5. Prototyping and Iterative Design:

Design software and CAD/CAM technology enable the rapid prototyping of injection molded parts through techniques such as 3D printing or CNC machining. This allows designers to physically test and evaluate the functionality, fit, and aesthetics of the parts before committing to mass production. CAD/CAM tools support iterative design processes by facilitating quick modifications and adjustments based on prototyping feedback, resulting in optimized part designs and reduced development cycles.

6. Collaboration and Communication:

Design software and CAD/CAM technology provide a platform for collaboration and communication among designers, engineers, and other stakeholders involved in the development of injection molded parts. These tools allow for easy sharing, reviewing, and commenting on designs, ensuring effective collaboration and streamlining the decision-making process. By facilitating clear communication and feedback exchange, design software and CAD/CAM technology contribute to optimized part designs and efficient development workflows.

7. Documentation and Manufacturing Instructions:

Design software and CAD/CAM technology assist in generating comprehensive documentation and manufacturing instructions for the production of injection molded parts. These tools enable the creation of detailed drawings, specifications, and assembly instructions that guide the manufacturing process. Accurate and well-documented designs help ensure consistency, quality, and repeatability in the production of injection molded parts.

Overall, design software and CAD/CAM technology are instrumental in optimizing injection molded parts. They enable designers and engineers to visualize, validate, optimize, and communicate designs, leading to improved part performance, manufacturability, and overall quality.

Can you explain the advantages of using injection molding for producing parts?

Injection molding offers several advantages as a manufacturing process for producing parts. It is a widely used technique for creating plastic components with high precision, efficiency, and scalability. Here’s a detailed explanation of the advantages of using injection molding:

1. High Precision and Complexity:

Injection molding allows for the production of parts with high precision and intricate details. The molds used in injection molding are capable of creating complex shapes, fine features, and precise dimensions. This level of precision enables the manufacturing of parts with tight tolerances, ensuring consistent quality and fit.

2. Cost-Effective Mass Production:

Injection molding is a highly efficient process suitable for large-scale production. Once the initial setup, including mold design and fabrication, is completed, the manufacturing process can be automated. Injection molding machines can produce parts rapidly and continuously, resulting in fast and cost-effective production of identical parts. The ability to produce parts in high volumes helps reduce per-unit costs, making injection molding economically advantageous for mass production.

3. Material Versatility:

Injection molding supports a wide range of thermoplastic materials, providing versatility in material selection based on the desired properties of the final part. Various types of plastics can be used in injection molding, including commodity plastics, engineering plastics, and high-performance plastics. Different materials can be chosen to achieve specific characteristics such as strength, flexibility, heat resistance, chemical resistance, or transparency.

4. Strength and Durability:

Injection molded parts can exhibit excellent strength and durability. During the injection molding process, the molten material is uniformly distributed within the mold, resulting in consistent mechanical properties throughout the part. This uniformity enhances the structural integrity of the part, making it suitable for applications that require strength and longevity.

5. Minimal Post-Processing:

Injection molded parts often require minimal post-processing. The high precision and quality achieved during the molding process reduce the need for extensive additional machining or finishing operations. The parts typically come out of the mold with the desired shape, surface finish, and dimensional accuracy, reducing time and costs associated with post-processing activities.

6. Design Flexibility:

Injection molding offers significant design flexibility. The process can accommodate complex geometries, intricate details, undercuts, thin walls, and other design features that may be challenging or costly with other manufacturing methods. Designers have the freedom to create parts with unique shapes and functional requirements. Injection molding also allows for the integration of multiple components or features into a single part, reducing assembly requirements and potential points of failure.

7. Rapid Prototyping:

Injection molding is also used for rapid prototyping. By quickly producing functional prototypes using the same process and materials as the final production parts, designers and engineers can evaluate the part’s form, fit, and function early in the development cycle. Rapid prototyping with injection molding enables faster iterations, reduces development time, and helps identify and address design issues before committing to full-scale production.

8. Environmental Considerations:

Injection molding can have environmental advantages compared to other manufacturing processes. The process generates minimal waste as the excess material can be recycled and reused. Injection molded parts also tend to be lightweight, which can contribute to energy savings during transportation and reduce the overall environmental impact.

In summary, injection molding offers several advantages for producing parts. It provides high precision and complexity, cost-effective mass production, material versatility, strength and durability, minimal post-processing requirements, design flexibility, rapid prototyping capabilities, and environmental considerations. These advantages make injection molding a highly desirable manufacturing process for a wide range of industries, enabling the production of high-quality plastic parts efficiently and economically.

<img src="https://img.hzpt.com/img/Injectionmoldedparts/Injectionmoldedparts-L1.webp" alt="China wholesaler Customized Molded CHINAMFG for Fixed Installation and Injection Moulding “><img src="https://img.hzpt.com/img/Injectionmoldedparts/Injectionmoldedparts-L2.webp" alt="China wholesaler Customized Molded CHINAMFG for Fixed Installation and Injection Moulding “>

editor by Dream 2024-10-14

China wholesaler Custom Polypropylene PP Plastic Injection Molded Products Toys Game Controller Computer Graphics Card Plastic Shell Injection Parts

Product Description

Custom Polypropylene Pp Plastic Injection Molded Products Toys Game Controller Computer graphics card Plastic Shell Injection Parts

We Design, Manufacture and Export Custom Molded Plastic Producrts to USA and European countries.

Use material of PP, ABS, LDPE, PS, HDPE, PVC, TPR, PC, PU, SBS, TPE and so on.

All of our products are Custom Moulded according to your Drawing, Sample and Idea. Till now we have produced products used for industrial, such as various industrial equipment components; Auto & MOTO, such as internal and external accessories, lights, rear-view mirrors, handles, bumpers and other components; Construction, plastic components for house insulation system, rain store system and drainage system; Daily use, such as CHINAMFG of fridge, air-condition, TV set; plastic case, container and box and so on; Garden tools, such as various plastic rakes, plastic tool handles; Furniture, various plastic caps for slat bed frame; other plastic accessories for furniture. We also do various multi purpose plastic interlocking floor tiles to be used for gymnasium, garage and office.

Product Description

| Item | Manufacturing Widely Application Custom Plastic Injection Molded Products | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Material | ABS, PC/ABS, PP, PC, POM, Nylon 6, Nylon 6/6, PA 12, HDPE, LDPE, PS(HIPS), Acrylic, SAN/AS, ASA, PVC, UPVC, TPE, TPR, PU, TPU, PET, PEI(Ultem), PSU, PPSU, PPE/PS, PTFE, GPPS, PPO, PES, CA, etc. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| If there is any special requirements on material performance, Such as Operating Temperature, UV resistance, UL standard, High transparent, Wear Resistance, Etc… If you do not know what kind of material to use, pls advise us what is the usage of these parts? Then we can make some recommend for you. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Performance | UV Resistance, Heat Resistance, Fire Resistance, Good Flexibility, etc. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Certificate | IATF 16949:2016 / ISO 9 Factory Address: No. 106 Longzi Road, Cunwei Village, CHINAMFG Town, HangZhou, ZheJiang , China 523468 Q6:How big is your factory? Q7:What is your monthly production capacity? Q8:How do you monitor the quality of your products? /* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1