Product Variety: DELI-001

Plastic Modling Variety: injection, Injection

Processing Services: Moulding

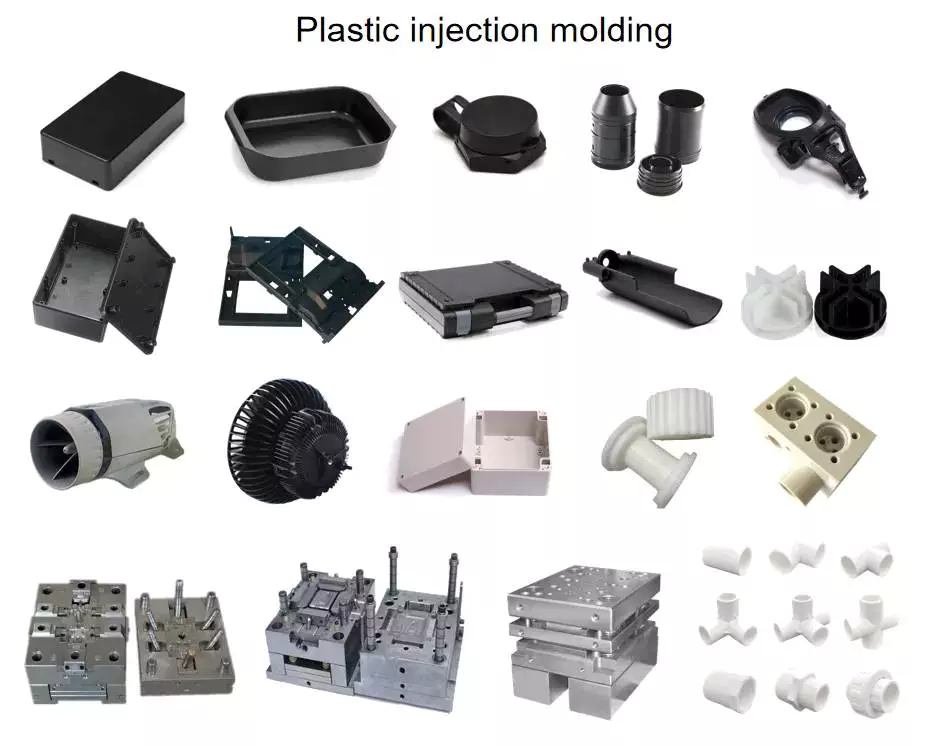

Solution Name: Plastic Injection Elements

Support: Personalize ODM OEM

Plastic elements material: Abs/Pc/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET Ect

Mould substance: P20/718/738/NAK80/S136/2738/2316

Mould Foundation: LKM CZPT Foundation

Drawing Format: 2nd/(PDF/CAD)3D(IGES/Step)

Surface area remedy: Polishing

Deal: Plastic Bag + Carton Box + Picket

MOQ: 1000pcs

Packaging Particulars: Plastic Bag + Carton Box + Picket

Port: HangZhou Port

| Item | High Top quality Manufacturing unit Plastic Injection Parts CNC Machining Peek PA66 GF30 Plastic Injection Molding Parts Go over Plastic Parts |

| Material | ABS, Pc/Abs, PP, Laptop, POM(Acetal/Delrin), Nylon 6, Nylon 6/6, PA twelve, HDPE, LDPE, PS(HIPS), PMMA(Acrylic), SAN/AS, ASA, China plastic components injection goods mildew Gentle CZPT plate injection molding PVC, UPVC,TPE, TPR, PU, TPU, PET, PEI(Ultem), PSU, PPSU, PPE/PS, PTFE(Teflon), GPPS, PPS, PPO, customized Plastic injection molding computer acrylic transparent plastic mold producing injection areas PES, CA, and many others. |

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /Attain/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

| Color | Almost all PMS shades obtainable. |

| Parameter | Inch, centimeter, millimeter, and many others. |

| Function | Industrial components /everyday offer / Health-related quality provide, and so on. |

| Surface Therapy | Matte, Widespread polishing, Mirror sharpening, Texture, Plating, Power Coating (Painting), Laser Engraving, Brushing, Marbling, Abs Pc PP Injection Goods Moulding makingTooling Plastic Car Parts Customized Plastic enclosure Printing and so on. |

| Mold Material | S136H, 718H, NAK80, P20, H13, etc. |

| Mold Precision | If no particular ask for, use to SJ/T10628-1995 expectations, class 3. |

| Mold Daily life-cycle | 100,000-five hundred,000 shots. |

| Packing | Pack in bulk / poly bag / bubble bag / colour box. |

| Sample | Available. A single cavity sample mould or 3D printing. |

| Price Suggestions | The value proven previously mentioned is just for reference, final genuine value depends on your layout, substance ask for, area remedy, orderqty, deal request, Personalized style injection mould for agricultural irrigation method molded parts and many others. |

Benefits of Injection Molded Parts in Design

Injection molded parts are manufactured from a variety of plastics. You can order samples of your desired product or download CAD drawings free of charge. For more information, visit our product catalog. There are numerous benefits of using injection molded products in your designs. Here are some of them. Injection molded products are cost-effective and highly customizable.

Design for manufacturability

Design for manufacturability (DFMA) is an important part of the design process for injection-molded parts. This process helps to minimize costs and streamline the production process. It also helps in the prevention of problems during the manufacturing process. The process involves several steps that include part geometry, location of critical surfaces, material selection, and dimensioning. It is also crucial to consider the colors and tolerances, which can help to minimize scrap rates.

Design for manufacturability (DFMA) is an important part of the design process for injection-molded parts. This process helps to minimize costs and streamline the production process. It also helps in the prevention of problems during the manufacturing process. The process involves several steps that include part geometry, location of critical surfaces, material selection, and dimensioning. It is also crucial to consider the colors and tolerances, which can help to minimize scrap rates.

Design for manufacturability is a vital early stage in the development process to ensure that the product is cost-effective and repeatable. It begins with a thorough understanding of the purpose for which the part is intended. The design process should take into account every aspect of the part, including the material section, tool design, and the production process.

DFM includes guidelines to ensure that the design meets the manufacturing requirements. These guidelines can include good manufacturing practices, as well as good design principles. Good design focuses on the quantity and quality of parts, as well as the complexity of their surfaces and tolerances. The process also focuses on mechanical and optical properties.

Injection molding design for manufacturability can save resources and time. It also reduces the costs of assembly. An injection molder conducts a detailed analysis of these design elements before starting the tooling process. This is not a standalone principle; it should be used in conjunction with other design optimization techniques.

Ideally, a product should be designed for optimum manufacture. This means that it should not have too many parts, or too few. To minimize this, the designer should choose a model that is easy to mold. Also, a design that does not require too many machine operations and minimizes risks.

Plastics used in injection molding

Injection molding is a very versatile process that uses various types of plastic polymers. These plastics are extremely flexible and can be molded to take on any shape, color, and finish. They can also be customized to contain design elements, text, and safety instructions. Plastics are also lightweight, easily recycled, and can be hermetically sealed to prevent moisture from getting into the product.

Injection molding is a very versatile process that uses various types of plastic polymers. These plastics are extremely flexible and can be molded to take on any shape, color, and finish. They can also be customized to contain design elements, text, and safety instructions. Plastics are also lightweight, easily recycled, and can be hermetically sealed to prevent moisture from getting into the product.

Plastics are categorized according to their properties, which can be helpful in selecting the right plastic for a particular application. Different materials have different degrees of hardness, which is important when it comes to molding applications. Some are harder than others, while others are more flexible. Plastics are ranked according to their Shore hardness, which was developed by CZPT.

Polystyrene is one of the most common plastics used in injection molding. However, it has a few disadvantages. While it is a good choice for simple products that do not require high strength and are prone to breakage, it is not ideal for items that need to be resistant to heat and pressure.

While many types of plastics are used in injection molding, choosing the right material is very important. The right material can make a big difference in the performance of your product and the cost of your product. Make sure to talk with your injection molding supplier to determine which plastic is right for your project. You should look for a plastic with a high impact rating and FDA approval.

Another commonly used plastic is PMMA, or polystyrene. This plastic is affordable and has a glass-like finish. It is often used for food and beverage packaging and can be easily recycled. This material is also used in textiles.Characteristics of polypropylene

Polypropylene injection molded parts offer an array of benefits, including a high degree of rigidity, excellent thermal stability, low coefficient of friction, and chemical resistance. These plastics are available in two main types, homopolymers and copolymers. Both types offer superior hardness and tensile strength. However, the material does not have the same fire-resistance as PE plastics.

Polypropylene is a colorless, odorless, crystalline solid. It is highly resistant to a variety of chemicals and is shatter-resistant. Its properties make it a great choice for many industrial applications, including packaging and containers for liquids. The material is also highly durable and can last for a very long time without breaking. In addition, it does not absorb or retain moisture, making it ideal for outdoor and laboratory applications.

Polypropylene is widely used for injection molding, and its low cost, flexibility, and resistance to chemical attack make it a popular choice. This material is also a great electrical insulator and has excellent thermal expansion coefficient. However, it is not biodegradable. Luckily, it can be recycled.

During the molding process, the temperature of the mold is a significant factor. Its morphology is related to the temperature and flow field, and a clear correlation between the two factors is essential. If you can control the temperature and flow, you can optimize your manufacturing process and eliminate costly trial-and-error procedures.

Polypropylene is an excellent electrical insulator and has a high dielectric coefficient. It can also be sterilized and resist high temperatures. Although it is less rigid than polyethylene, it is a good choice for applications where electrical insulation is necessary.

Texture of injection molded parts

Texture design is a common feature of injection molded parts, which helps to raise the perceived value of the vehicle. While traditional manufacturing processes can produce limited textures, additive manufacturing allows for infinite designs. For example, a design that looks like a wood grain pattern may be printed on an aluminum car part.

Texture design is a common feature of injection molded parts, which helps to raise the perceived value of the vehicle. While traditional manufacturing processes can produce limited textures, additive manufacturing allows for infinite designs. For example, a design that looks like a wood grain pattern may be printed on an aluminum car part.

Texture is important because it can improve the strength of the part and enhance its adhesion to other surfaces. Moreover, textured parts can resist damage from contact and fingerprints. This makes them more durable and a good option for further molding operations. Injection molding processes usually follow a set of standards from the Society of Plastics Industry, which define different types of surface finishes.

Textured plastic injection molded parts may have various types of surfaces, including wood grain, leather, sand, or stipple. Choosing the right surface texture is crucial for enhancing the appearance of the part, but it must also be compatible with its function. Different materials have different chemical and physical properties, which can influence the type of texture. Moreover, the melting temperature of the material is important for its surface finish. The additives used in the process can also have an impact on the surface finish.

Texture can also vary between manufacturers and types of components. Some textures are flat, while others are rough. The top row corresponds to A3 and B4 in flatness, while the bottom row shows rough surfaces. These rough surfaces may damage sensitive testing equipment. However, some textures may have near equivalence with each other, namely SPI D-3 and MT-11020.

The type of texture that is applied to injection molded parts can affect the minimum draft angle required for the parts to be ejected. Parts with light texture tend to be smoother than parts with heavy textures, while parts with heavy textures require a higher draft angle. The draft angle for heavy textures should be between five and 12 degrees. It is best to consider this early in the design process and consult with the injection molder to get a good idea of the necessary draft angles.

editor by czh2023-02-15

Injection molded parts must meet certain design considerations to ensure quality and precision. Design considerations include proper material choice, process control, and tool design. In addition, designers must consider the tolerance ranges for the parts to be produced. These tolerances will differ from molder to molder, and designers should discuss their specific needs with their molders before they begin production. Designers must also consider possible revisions to the mold, such as making the part more or less tighter.

Injection molded parts must meet certain design considerations to ensure quality and precision. Design considerations include proper material choice, process control, and tool design. In addition, designers must consider the tolerance ranges for the parts to be produced. These tolerances will differ from molder to molder, and designers should discuss their specific needs with their molders before they begin production. Designers must also consider possible revisions to the mold, such as making the part more or less tighter. Injection molding is a process in which plastic parts are formed by pressing melt into a mold. The process takes place in two stages. During the first step, the material is injected and heated, while the second stage is when the mold is opened and the part ejected. The part is then finished and ready for use.

Injection molding is a process in which plastic parts are formed by pressing melt into a mold. The process takes place in two stages. During the first step, the material is injected and heated, while the second stage is when the mold is opened and the part ejected. The part is then finished and ready for use. The cost of injection molded parts depends on many factors, including the complexity of the part and the mold design. Simpler designs, fewer CAD steps and simpler processes can help companies minimize costs. Another factor that affects the cost of injection molded parts is the geometry of the part. In general, complex geometries require more design work and tooling time. Additionally, thicker walls require more material than thin ones, which raises the cost of the part.

The cost of injection molded parts depends on many factors, including the complexity of the part and the mold design. Simpler designs, fewer CAD steps and simpler processes can help companies minimize costs. Another factor that affects the cost of injection molded parts is the geometry of the part. In general, complex geometries require more design work and tooling time. Additionally, thicker walls require more material than thin ones, which raises the cost of the part. When creating a new part, or updating an existing part, design considerations for injection molded parts are critical. The decisions you make in these early stages of development can have a profound effect on the final product, and they can also have substantial cost and timing implications. In this guide, we’ll explore key design considerations, including how to maximize the efficiency of the injection molding process. We’ll also touch on how to optimize gate placement and parting lines.

When creating a new part, or updating an existing part, design considerations for injection molded parts are critical. The decisions you make in these early stages of development can have a profound effect on the final product, and they can also have substantial cost and timing implications. In this guide, we’ll explore key design considerations, including how to maximize the efficiency of the injection molding process. We’ll also touch on how to optimize gate placement and parting lines. Material compatibility is important for the durability of your injection molded parts. You can use multiple materials in the same part by mixing resins. This is an ideal solution for parts that require adhesion, friction, or wear. Fast Radius can simplify the material selection process, optimize part design, and speed up production.

Material compatibility is important for the durability of your injection molded parts. You can use multiple materials in the same part by mixing resins. This is an ideal solution for parts that require adhesion, friction, or wear. Fast Radius can simplify the material selection process, optimize part design, and speed up production. Tooling fabrication for injection-molded parts is an important component of the manufacturing process. The right design of the mold can reduce the cost and time required for a finished product. For instance, choosing the right type of core for the mold can reduce the amount of material used in the part, which is necessary to produce a high-quality product. It is also important to choose a design that is easy to mill into a mold.

Tooling fabrication for injection-molded parts is an important component of the manufacturing process. The right design of the mold can reduce the cost and time required for a finished product. For instance, choosing the right type of core for the mold can reduce the amount of material used in the part, which is necessary to produce a high-quality product. It is also important to choose a design that is easy to mill into a mold. Injection molding is the process of manufacturing plastic parts. It uses thermoplastic, thermoset, or elastomers to manufacture components. The range of materials is enormous and includes tens of thousands of different polymers. They are blended with other materials and alloys to produce a wide range of properties. Designers select the appropriate materials for the job based on the properties and functions desired in the finished part. During the mold design process, mold materials must be carefully chosen, as different materials require different molding parameters.

Injection molding is the process of manufacturing plastic parts. It uses thermoplastic, thermoset, or elastomers to manufacture components. The range of materials is enormous and includes tens of thousands of different polymers. They are blended with other materials and alloys to produce a wide range of properties. Designers select the appropriate materials for the job based on the properties and functions desired in the finished part. During the mold design process, mold materials must be carefully chosen, as different materials require different molding parameters. Injection molded parts exhibit a range of mechanical and physical properties. These properties affect the performance of the parts. For example, they can affect electrical conductivity. Also, the degree of filling in the parts can determine their mechanical properties. Some studies have even found that filling content can affect the dimensional accuracy of the parts.

Injection molded parts exhibit a range of mechanical and physical properties. These properties affect the performance of the parts. For example, they can affect electrical conductivity. Also, the degree of filling in the parts can determine their mechanical properties. Some studies have even found that filling content can affect the dimensional accuracy of the parts. Injection molded parts often use fasteners for securing fastener elements in place. As shown in FIGS. 7 and 8 (two separate views), the fastener elements are integrated with the molded product, and they extend from one side. The fastener elements are designed to engage loop elements in the overlying layer. The palm-tree shaped fasteners are especially well-suited for this purpose, as their three-dimensional sides engage more loops than flat sides. These features result in a more secure closure.

Injection molded parts often use fasteners for securing fastener elements in place. As shown in FIGS. 7 and 8 (two separate views), the fastener elements are integrated with the molded product, and they extend from one side. The fastener elements are designed to engage loop elements in the overlying layer. The palm-tree shaped fasteners are especially well-suited for this purpose, as their three-dimensional sides engage more loops than flat sides. These features result in a more secure closure. One of the most critical design factors for injection molded parts is the wall thickness. The wall thickness affects many key characteristics of the part, from its surface finish to its structural integrity. Proper consideration of this factor can prevent costly delays due to mold issues or mold modifications. To avoid this problem, product designers must carefully consider the functional requirements of the part to determine the minimum and nominal wall thickness. In addition, they must also consider acceptable stress levels, since parts with excessively thin walls may require excessive plastic pressure and may create air traps.

One of the most critical design factors for injection molded parts is the wall thickness. The wall thickness affects many key characteristics of the part, from its surface finish to its structural integrity. Proper consideration of this factor can prevent costly delays due to mold issues or mold modifications. To avoid this problem, product designers must carefully consider the functional requirements of the part to determine the minimum and nominal wall thickness. In addition, they must also consider acceptable stress levels, since parts with excessively thin walls may require excessive plastic pressure and may create air traps. Surface finishes on injection molded parts are often used to mask defects, hide wear and tear, or enhance a product’s appearance. These finishes can also be useful when the product will come in contact with people’s hands. The surface texture you choose will depend on your desired functionality as well as the way you want to use the product. Generally, rougher textures provide better grip while masking minor molding imperfections. However, they can also make a product more difficult to release from the mold. This means that you may have to increase the draft angle of the mold. In order to get the best surface finish, the toolmaker and product designer must collaborate closely early in the design process.

Surface finishes on injection molded parts are often used to mask defects, hide wear and tear, or enhance a product’s appearance. These finishes can also be useful when the product will come in contact with people’s hands. The surface texture you choose will depend on your desired functionality as well as the way you want to use the product. Generally, rougher textures provide better grip while masking minor molding imperfections. However, they can also make a product more difficult to release from the mold. This means that you may have to increase the draft angle of the mold. In order to get the best surface finish, the toolmaker and product designer must collaborate closely early in the design process. The production volume of injection molded parts varies depending on the material being used. Large volumes of parts are expensive to produce, while small quantities can be produced for low cost. Injection molding requires a precise mold, which is CNC-machined from tool steel or aluminum. The mold has a negative of the part that is injected, a runner system, and internal water cooling channels to aid in cooling the part. Recent advances in 3D printing materials have made it possible to produce molds for low-volume injection molding. Previously, this was not financially viable due to the high cost of traditional mold making.

The production volume of injection molded parts varies depending on the material being used. Large volumes of parts are expensive to produce, while small quantities can be produced for low cost. Injection molding requires a precise mold, which is CNC-machined from tool steel or aluminum. The mold has a negative of the part that is injected, a runner system, and internal water cooling channels to aid in cooling the part. Recent advances in 3D printing materials have made it possible to produce molds for low-volume injection molding. Previously, this was not financially viable due to the high cost of traditional mold making.